Hot erasing head for erasing erasable medium and printer thereof

A recording medium and heating element technology, applied in printing and other directions, can solve problems such as errors, differences, and the effect of erasing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

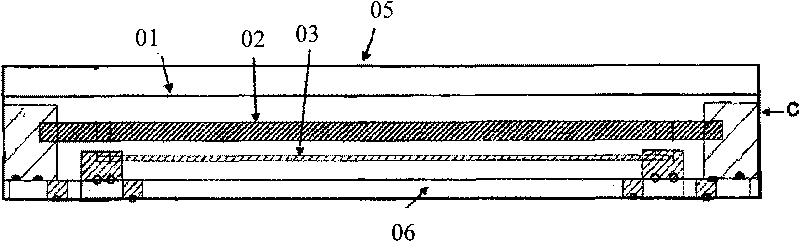

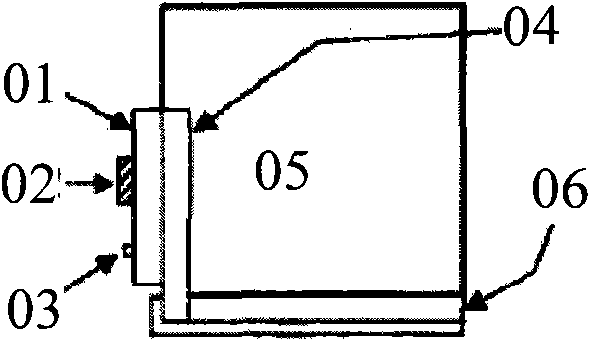

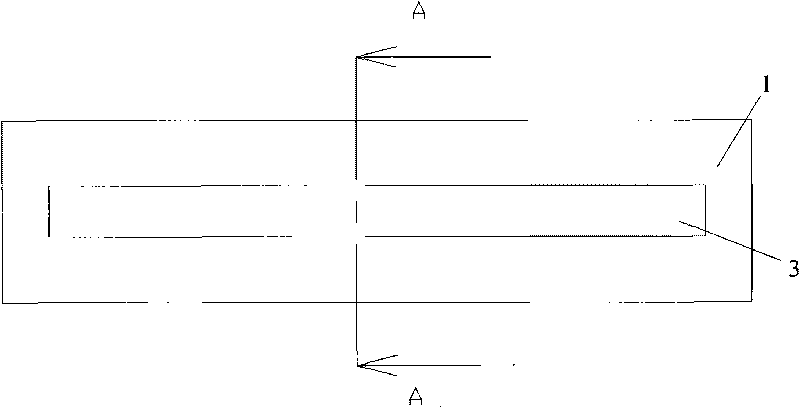

[0031] image 3 It is a schematic top view of the erasing head provided by the first embodiment of the present invention. Figure 4 yes image 3 Schematic diagram of the cross-section in the direction of A-A. Combine below image 3 , 4 The structure of the erasing head of the present invention will be described.

[0032] As shown in the figure, the erasing head is in the shape of a strip and is composed of multiple vertically arranged functional layers. Taking the surface facing the recording medium during operation as the upper surface, it includes heat sink 1, substrate 2, heating element 3, insulating layer 4, temperature detection layer 5 and protective film 6 from bottom to top in the cross section perpendicular to the length direction. . In this embodiment, the material of the substrate 2 is ceramics, and its upper surface is covered with a layer of glass glaze 20 with heat insulation function. The heating element 3 is covered on the surface of the glass glaze 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com