All-terrain high-speed telescopic arm forklift truck

A telescopic boom, all-road technology, applied in the direction of the hoisting device, etc., can solve the problems of not being able to keep up with the speed of the transport fleet, low transmission efficiency in transition, poor operating comfort, etc. Fast, high traction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

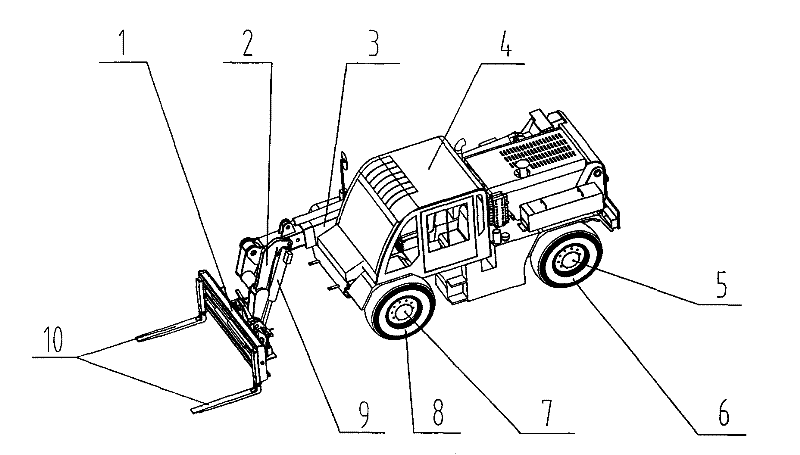

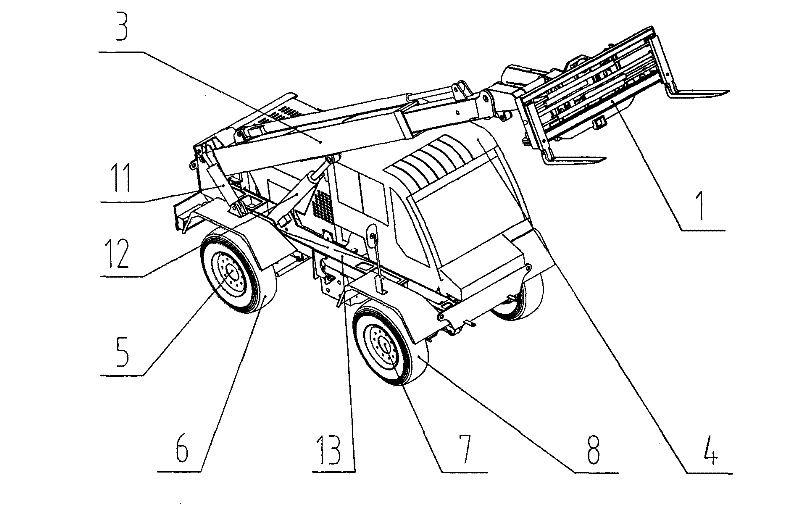

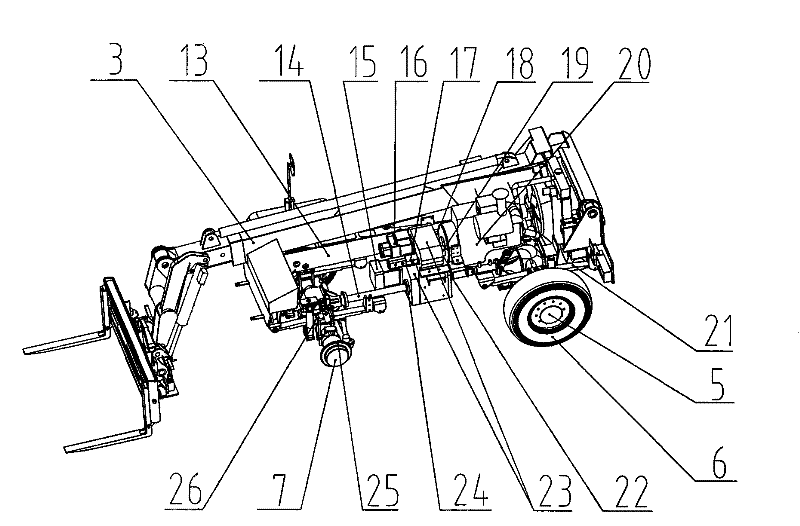

[0016] refer to figure 1 , 2 , shown in 3, the present invention comprises an integral vehicle frame chassis 13, front and rear axles 7,5 are set on the vehicle frame 13, closed cab 4 is arranged on the left side of the front end of the vehicle frame 13, and telescopic Arm working mechanism 3, the front end of telescopic arm working mechanism 3 is connected to folding arm mechanism 2, and the front end of folding arm mechanism 2 is connected to working device 1. Two single cargo forks 10 are arranged in the working device 1, and the two single cargo forks 10 can be folded up and work together. The device 1 is combined to meet the safety of high-speed driving. The folding arm mechanism 2 is provided with a leveling cylinder 9, which is connected to the working device 1. Telescopic arm working mechanism 3 links to each other with vehicle frame 13, and vehicle frame 13 middle part is provided with lifting oil cylinder 12, and rear portion is provided with compensating oil cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com