Method for lifting inverted cone shell water tank of reinforced concrete water tower

A technology of a concrete water tower and an inverted conical shell is applied in the field of lifting the inverted conical shell water tank of a reinforced concrete water tower, and can solve the problems of water tank sliding loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

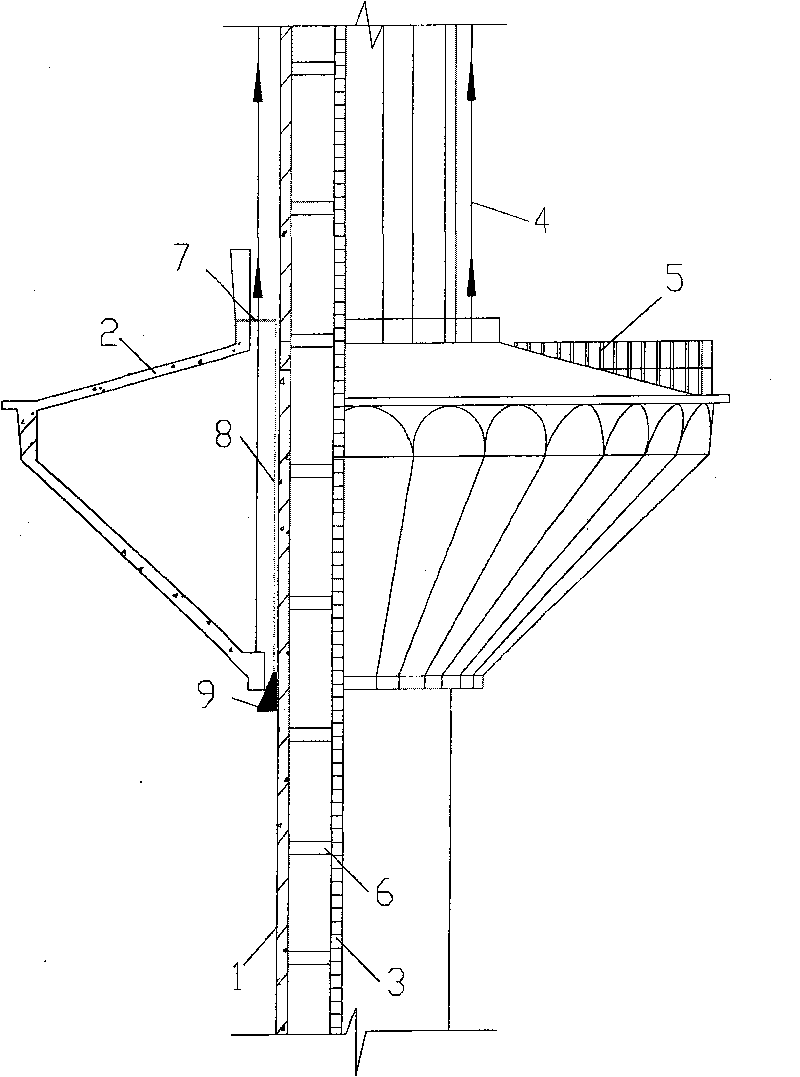

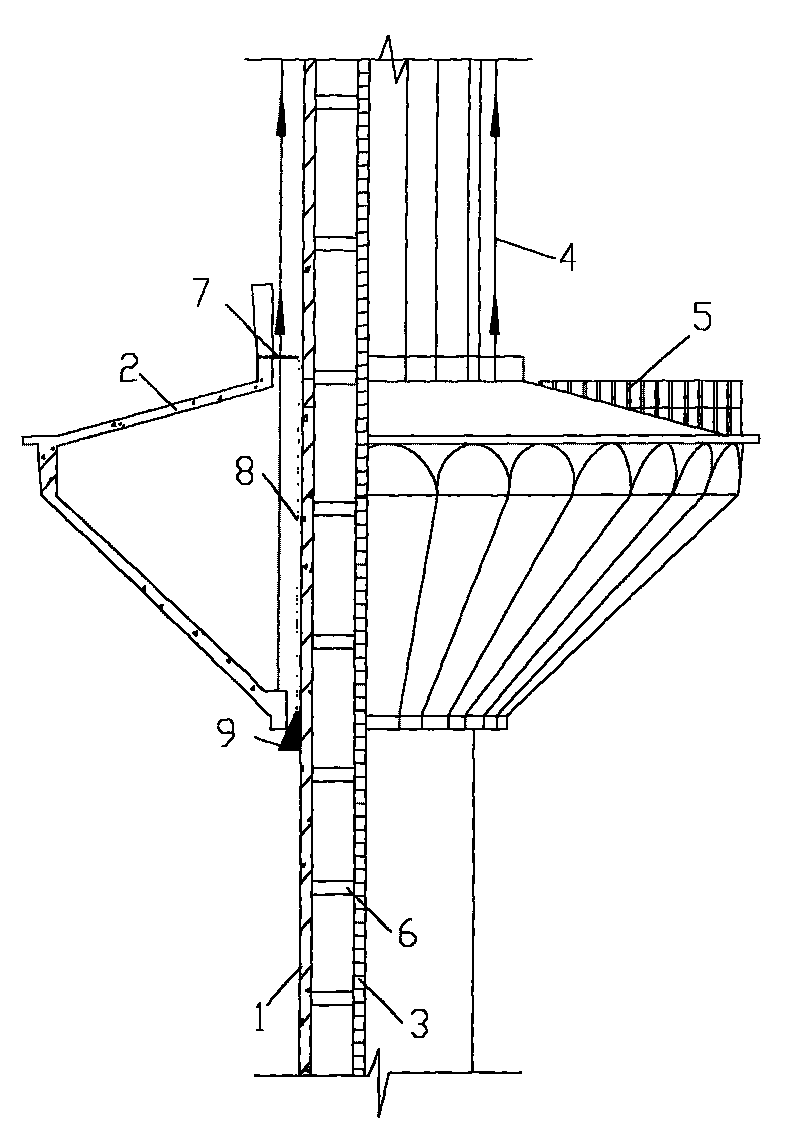

[0009] With reference to accompanying drawing, concrete steps of the present invention are:

[0010] (1) The boom 4 is positioned, and the hydraulic equipment is in place. The hydraulic equipment uses the QYD-50 jack used in the sliding form, and is installed upside down on the ring beam of the lifting bracket.

[0011] (2) The initial rise of the water tank: adjust the pressure of the overflow valve to 0.5MPa, start the oil pump, and the clamp head of the jack drives the boom to raise the water tank slowly. Comprehensive inspection of hydraulic piping system, boom and water tank cabinet structure. At the same time, remove the wooden squares, wooden boards, and sand and skids in the gaps at the bottom of the water tank. The boom 4 rises to drive the water tank to rise.

[0012] (3) steel wedge installation,

[0013] The installer enters the top cover 2 of the water tank from the opening of the support wall 1, sets up the suspension rod 7, hangs the rising steel wedge 9 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com