Method for laying out raw material grinding mill workshop building

A plant layout and raw material grinding technology, which is applied in industrial buildings and other fields, can solve problems such as the need to increase the cap foundation, the large investment in plant construction, and the large investment in personnel, so as to shorten the construction time, shorten the construction period, and ensure the safety of the construction process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

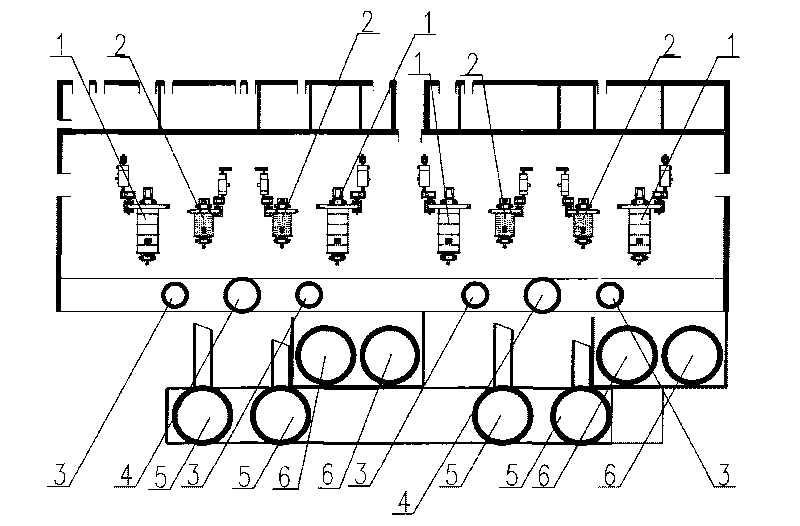

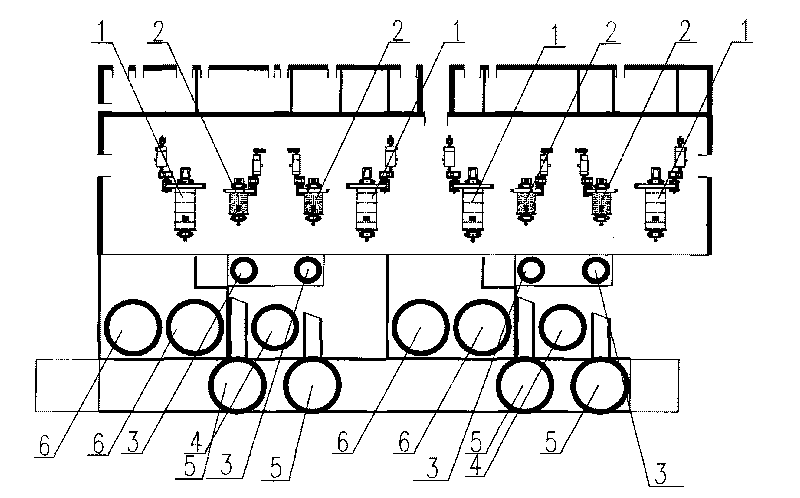

[0015] image 3 It is a plan view of the raw material mill room layout obtained by the raw material mill room layout method according to an embodiment of the present invention. Such as image 3 As shown, the raw material mill building comprises four ball mills 1, four rod mills 2, four classifiers 3, two lime bins 4, four raw ore bins 5, four pulp tanks 6 and four grinding conveyor belts (in image 3 Not shown in ), corresponding to the formation of four raw material process lines. Because the amount of lime added is relatively small, one lime silo corresponds to two raw material process lines, that is, one lime silo adds lime to the bauxite in the two grinding conveyor belts at the same time through a conveyor belt or other means. In the method for arranging the raw material mill building according to an embodiment of the present invention, the lime bin 4 is arranged separately from the factory building column, that is, the lime bin 4 and the factory building column are sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com