Method for constructing subway station air shaft for soft soil strata

A technology for subway stations and construction methods, which is applied to earthwork drilling, well sinking, shaft equipment, etc., which can solve the problems of large impact on urban environment, influence on construction progress, and many departments in coordination and cooperation, so as to achieve low construction indirect costs and realize The effect of safe construction and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

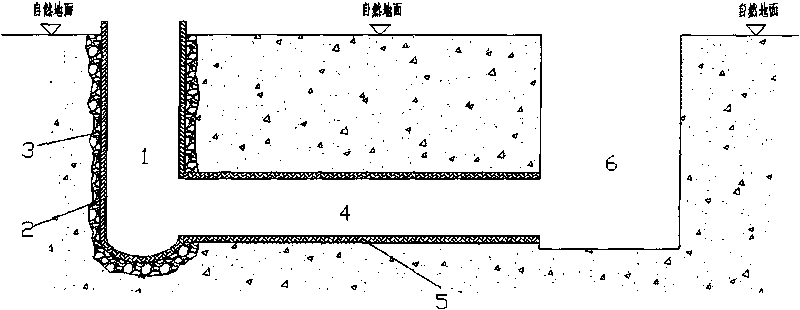

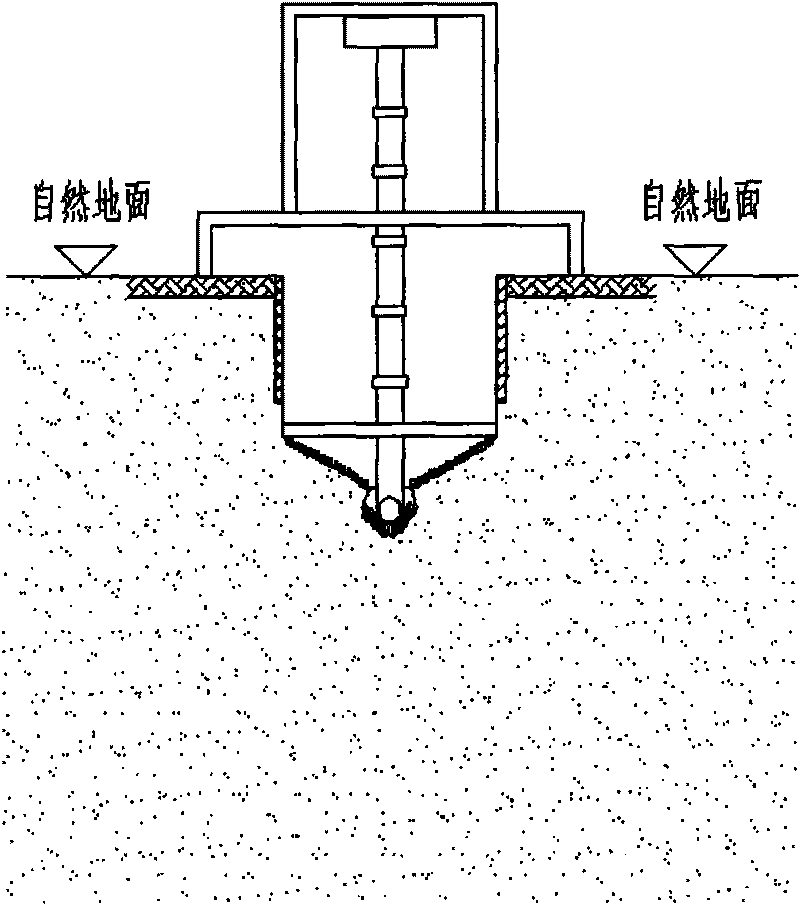

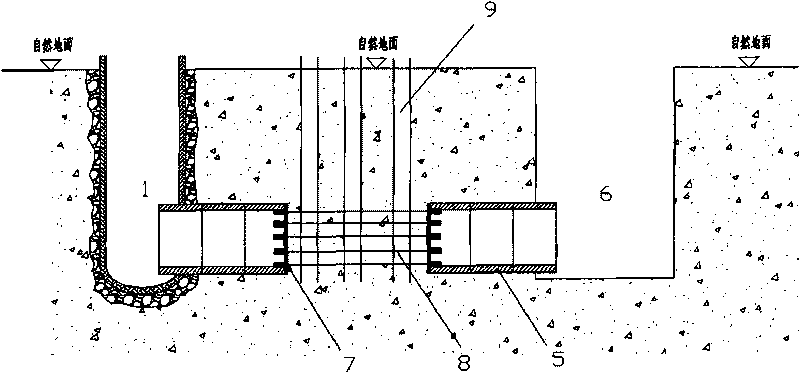

[0023] Depend on Figure 1-Figure 4 As shown, a kind of construction method that is used for the air shaft of subway station in soft soil stratum provided by the embodiment of the present invention is characterized in that, concrete implementation steps:

[0024] 1) drilling

[0025] Utilize the "drilling method" to drill into row and air intake shaft 1, and once drilled to the bottom, the inner diameter of the air intake shaft is 4m, the inner diameter of the exhaust shaft is 5m, and the drilling depth exceeds a certain distance from the bottom plane of the horizontal box culvert 5. During the drilling process, high-quality Mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com