Variable displacement turbine

A technology for turbines and turbine shafts, which is applied to gas turbine devices, mechanical equipment, engine components, etc., and can solve problems such as complex axial casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. When the shapes, relative positions and other aspects of parts described in the embodiments are not clearly defined, the scope of the present invention is not limited to the parts shown in the drawings, and the contents shown in the drawings are only illustrative.

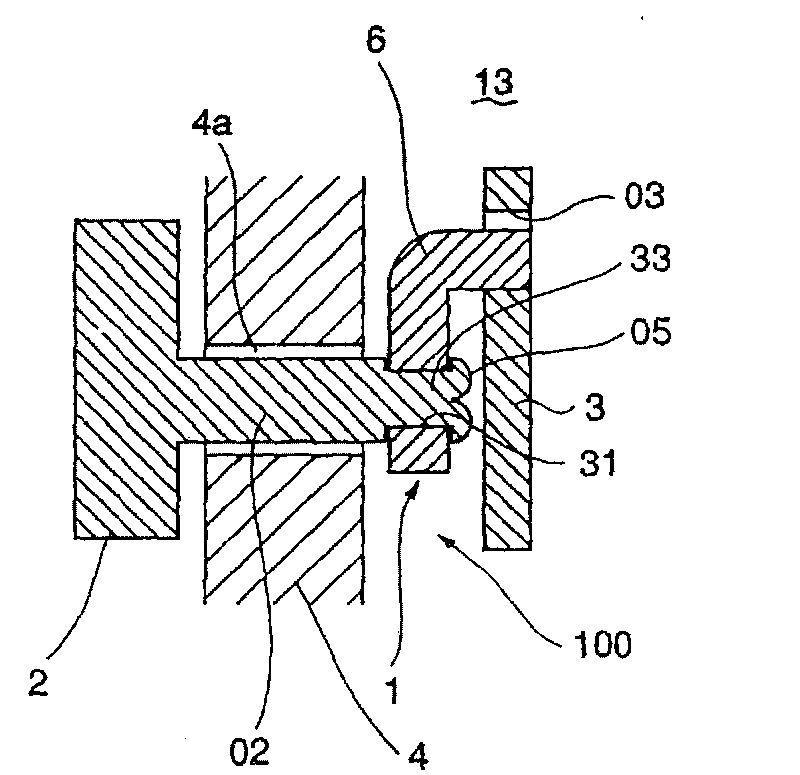

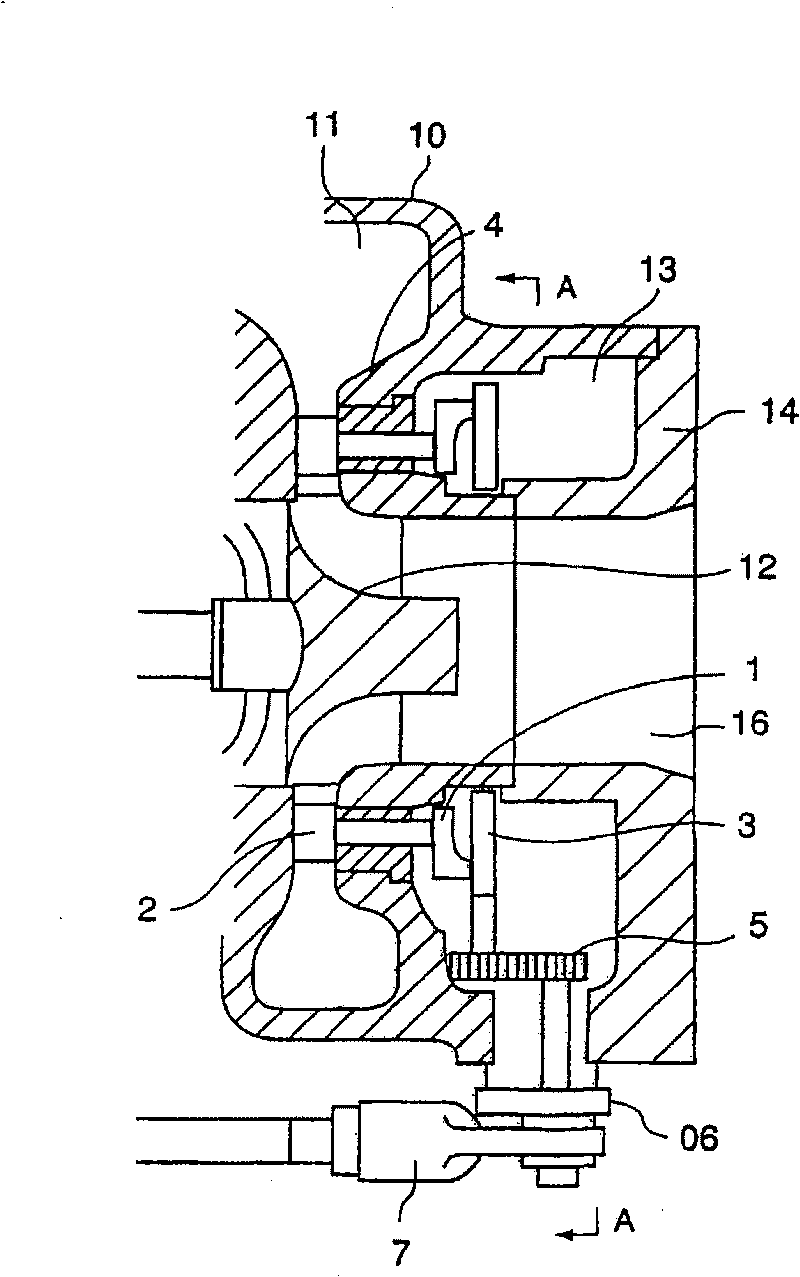

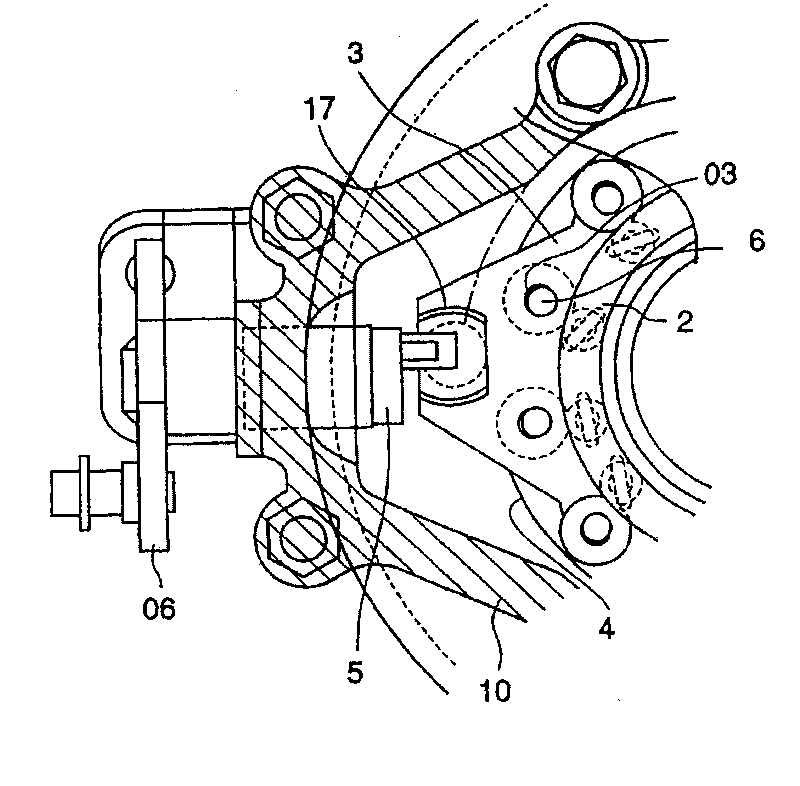

[0031] figure 1 It is a cross-sectional view of the essential parts of the nozzle adjustment mechanism in the supercharger with variable volume turbine according to the first preferred embodiment of the present invention. figure 2 is a sectional view taken along the axis of the variable capacity turbine of the first embodiment. exist figure 2 Among them, the parts belonging to the prior art are in Figure 5shown in . image 3 for along figure 2 Sectional view taken along line A-A. Figure 4 for corresponding to figure 1 The sectional view of the second embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com