Valve control liquid-filled coupler of high-power conveyor

A conveyor, high-power technology, used in mechanical equipment, fluid transmission devices, belts/chains/gears, etc., can solve the problems of difficult starting and unbalanced load of high-power conveyors, and achieve compact structure, safety, stability and reliability. Powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

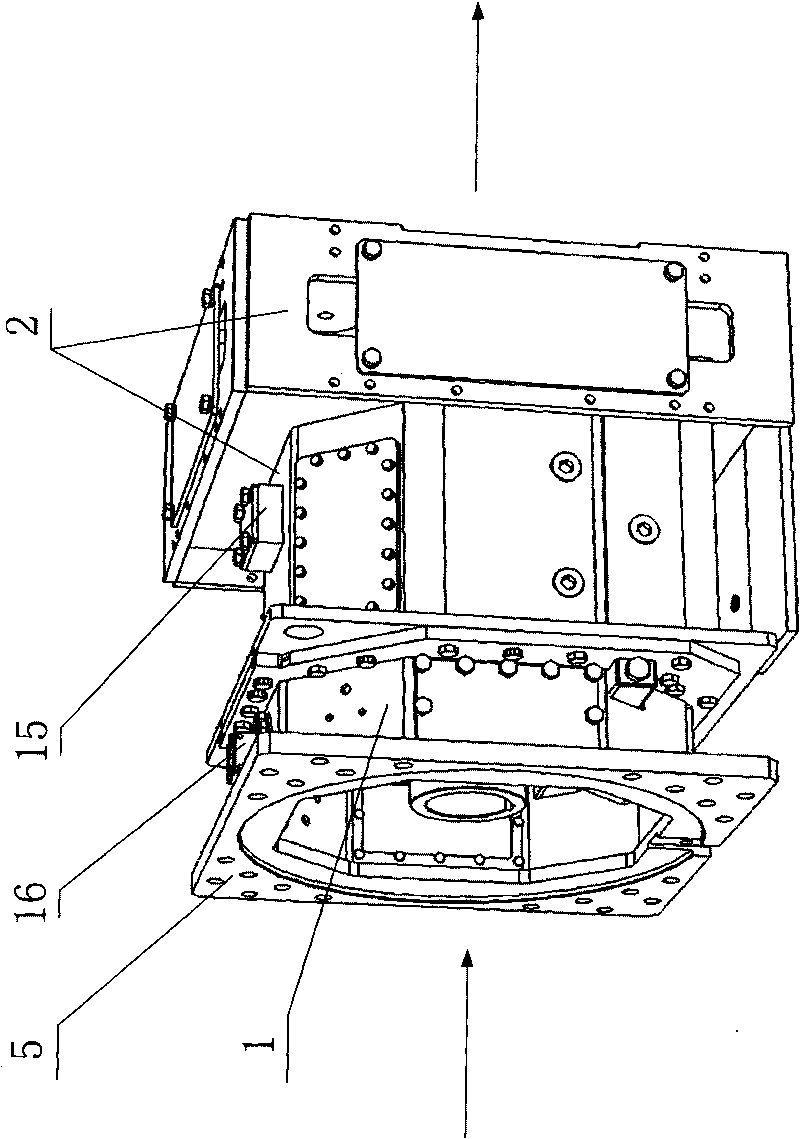

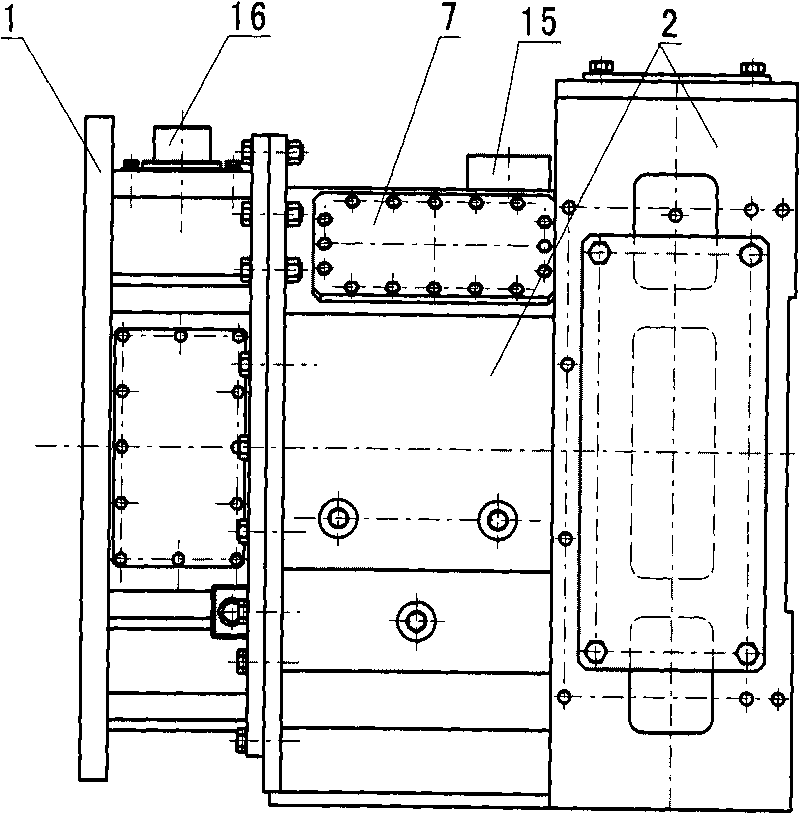

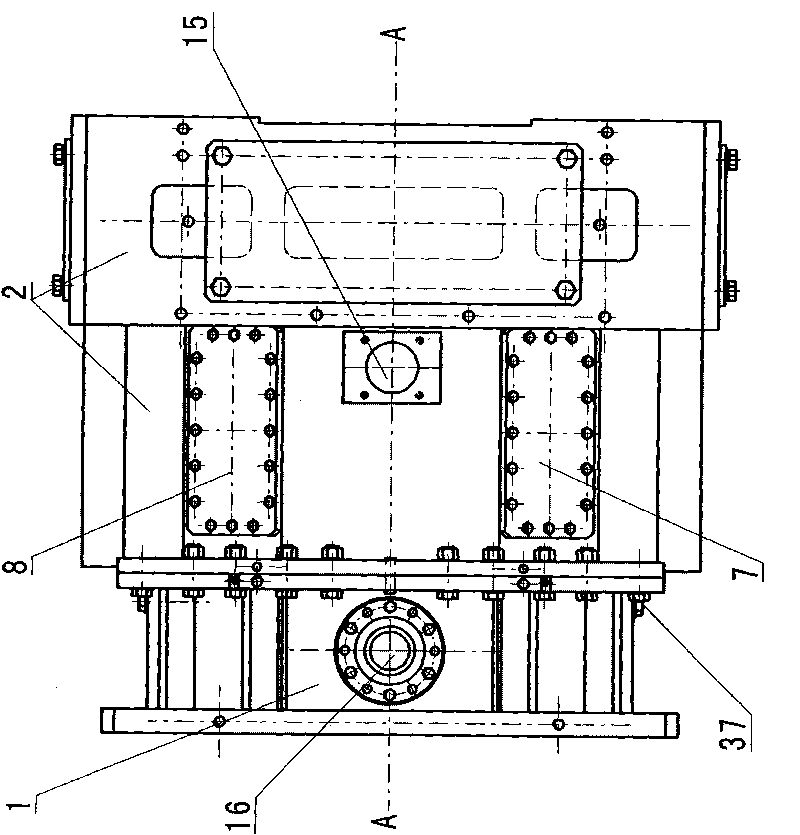

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] figure 1 , 2 , 3, 4, 5, and 6 are the overall structure diagram, the position and connection relationship of each part must be correct, and the installation should be firm.

[0027] The left and right boxes can be made of stainless steel, which should have good strength and corrosion resistance.

[0028] This structure has no bearing support, and there is no problem of bearing corrosion.

[0029] The fluid paths of filling and draining should be unimpeded and clean without being blocked.

[0030] Set the temperature and filling volume sensors to effectively grasp the temperature and filling volume information of the working chamber, which is used to control the filling volume of the working chamber and monitor the temperature.

[0031] The left part of the coupler is connected by the conveyor motor shaft extending into the coupler shaft sleeve, and the right part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com