Micro electro mechanical system (MEMS) technology-based viscosity transducer chip and preparation method thereof

A technology of viscosity sensor and micro-electro-mechanical system, which is applied in the field of silicon micro-cantilever chip and its preparation based on MEMS technology, can solve the problems of bulky instruments, mostly analog signals, difficult cleaning, etc., and achieve high sensitivity and high measurement accuracy , output large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

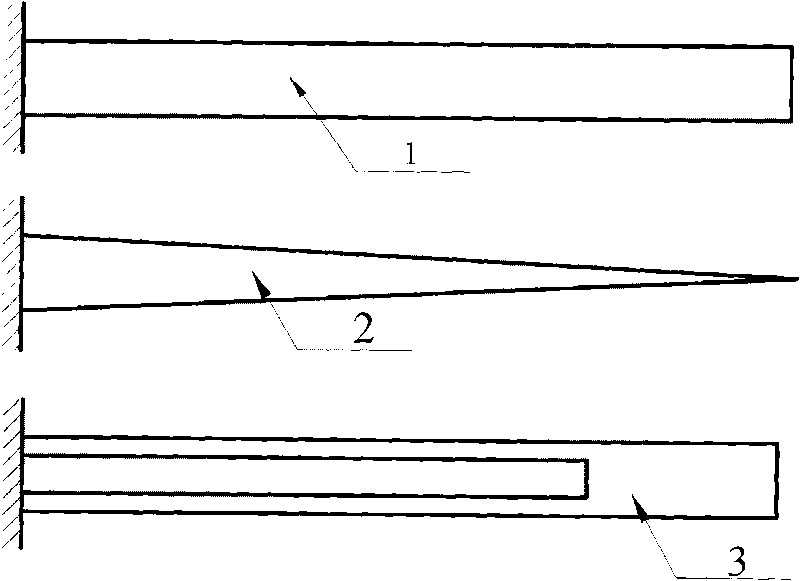

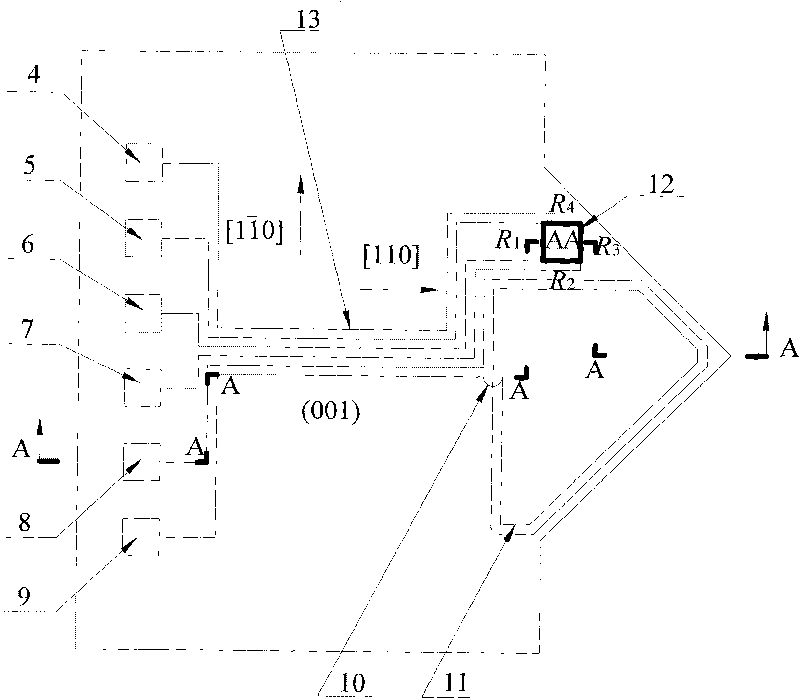

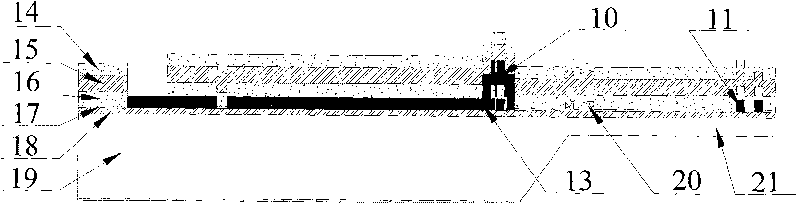

[0016] The eigenfrequency of the rectangular beam 1, the triangular beam 2 and the U-shaped beam 3, the structure and preparation process of the MEMS triangular silicon micro-cantilever chip according to the present invention, and the working principle of the chip are described in more detail below in conjunction with the accompanying drawings.

[0017] refer to figure 1 , the eigenfrequencies of rectangular beam 1 and triangular beam 2 are:

[0018] f = 1 2 π K m * = 1 2 π Ebd 3 4 l 3 × 0.24 ρ s bld = ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap