Silicon wafer bearing table for photoetching machine and use method thereof

A technology of a bearing table and a lithography machine, which is used in microlithography exposure equipment, photolithography process exposure devices, etc., can solve problems such as affecting the quality of products in subsequent operations, waste of lithography resources, affecting product quality, etc., and avoid frontal graphics. Out-of-focus phenomenon, reduce manufacturing cost, reduce the effect of lithography rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

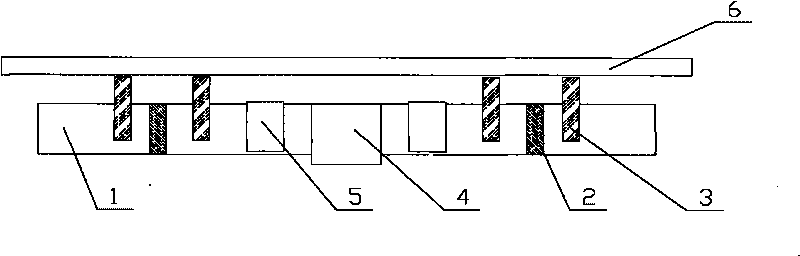

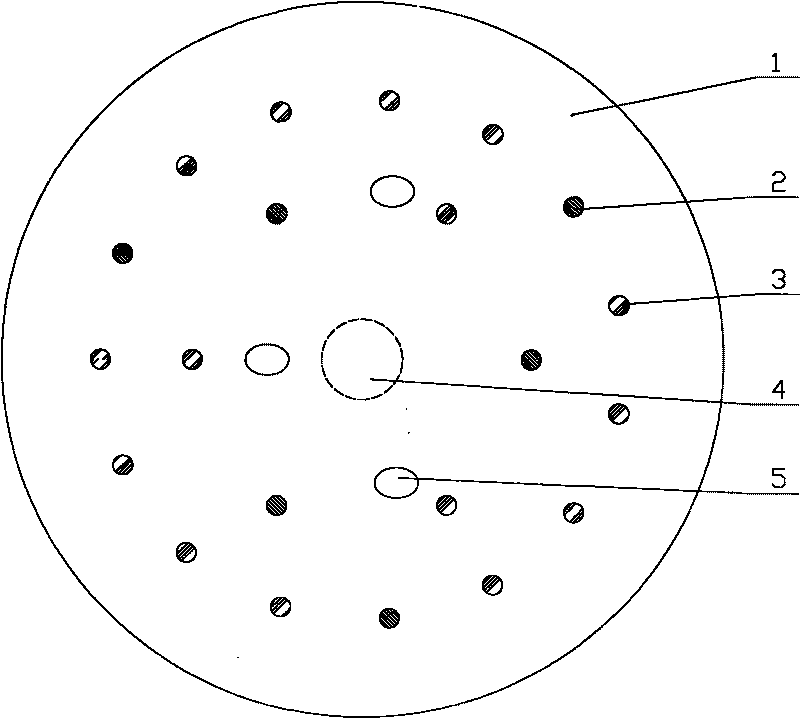

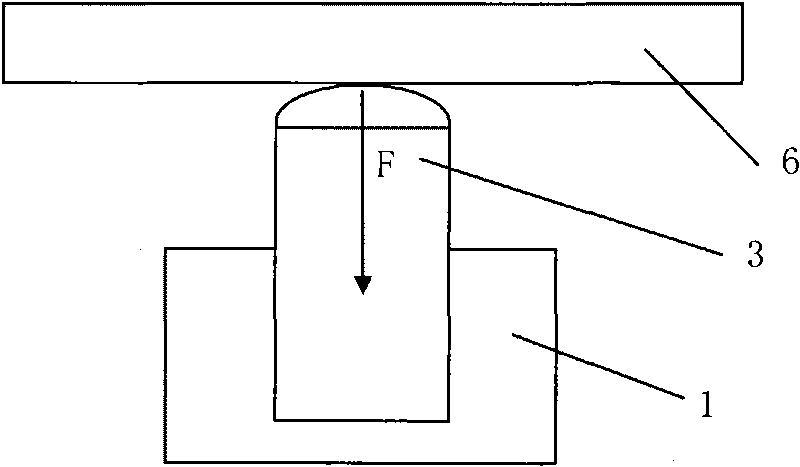

[0024] Such as figure 1 , figure 2 As shown, the silicon wafer carrying platform of the lithography machine of the present invention includes a carrying platform base 1, a vacuum hole 2, a stress sensor 3, a connector 4, and a silicon wafer receiving device 5; the carrying platform base 1 is provided with a plurality of vacuum The hole 2 and the silicon chip receiver 5; the bottom of the carrier base 1 is provided with a connector 4.

[0025] The vacuum hole 2 is used for vacuuming the silicon wafer 6 to fix the silicon wafer 6 . The silicon wafer receiver 5 is used for receiving and sending the silicon wafer 6 . There is a clearance fit between the carrier base 1 and the silicon wafer transfer device 5 , and the silicon wafer transfer device 5 can stretch up and down on the carrier base 1 to facilitate the transfer of the silicon wafer 6 . The connector 4 fixes the stage base 1 on the photolithography machine.

[0026] The shape of the carrier base 1 can be circular, rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com