Paper mill cogeneration energy system optimization system and working method thereof

A technology of system optimization and combined heat and power generation, applied in manufacturing computing systems, instruments, technology management, etc., can solve problems such as uneconomical system operation and unscientific manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0150] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0151] The system of the present invention is used to optimize the operation of the energy system of a papermaking enterprise in a cogeneration mode. The energy conversion link of the enterprise includes 4 fluidized bed boilers, 4 extraction condensing turbines and a number of temperature and pressure reduction equipment. thermal system. The working method is as follows:

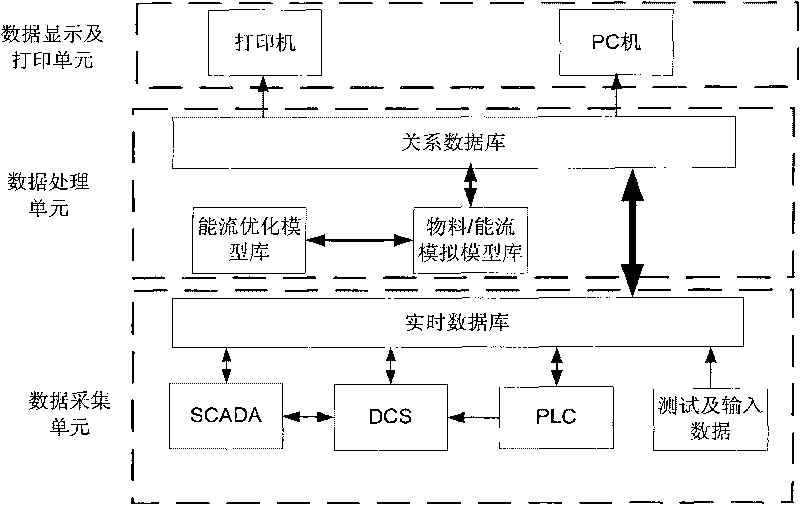

[0152] first step, such as image 3 , 5 As shown, the energy consumption related data of each department is collected from the SCADA, PLC, DCS and data collectors in the pulp and paper production line, thermal power workshop, water treatment workshop, office dormitory, canteen and other production and living assistance workshops. The obtained data is stored in the real-time database for calling by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com