Ultrahigh pressure pulse silicon rectifier stack

A pulse rectification and ultra-high voltage technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of low silicon stack frequency, low silicon stack operating voltage, and inability to achieve MHz pulse rectification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

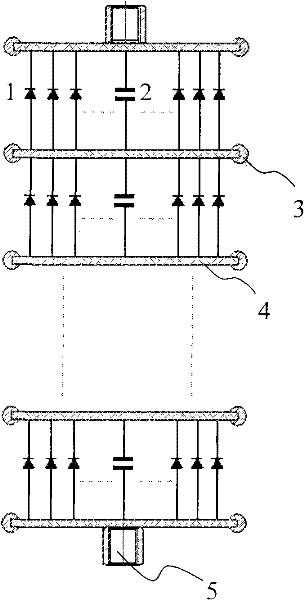

[0023] Embodiment 1: The metal plate in this embodiment adopts a thin metal plate on a double-sided printed circuit board. Diodes are evenly welded on the periphery of the wafer double-sided printed circuit board 4 according to the actual number of parallel connections, and the central part is welded with a voltage equalizing capacitor 2. Each layer is cylindrical, and the whole is also cylindrical. A shim ring 3 is added to the edge of the double-sided printed circuit board 4 of the wafer to homogenize the local field strength, and the number of series series is determined according to the required working voltage. The metal sheets on both sides of the double-sided printed circuit board are electrically connected.

Embodiment 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the metal plate is a whole metal plate, and the diodes and capacitors of two adjacent layers share one metal plate.

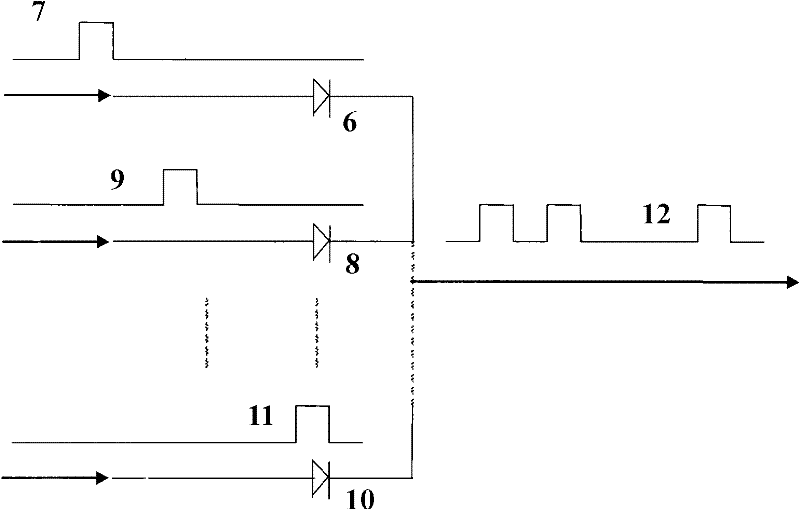

[0025] The purpose of pulse synthesis can be achieved by connecting multiple ultra-high voltage pulse rectifier silicon stacks of the present invention in parallel, such as image 3 . First, the first ultra-high voltage single pulse 7 is delivered to the load through the first ultra-high voltage pulse rectifier silicon stack 6, and at this time, except the first silicon stack is turned on, other silicon stacks are turned off in reverse; then, the second The ultra-high voltage single pulse 9 is delivered to the load through the second ultra-high voltage pulse rectifier silicon stack 8. At this time, except the second silicon stack is turned on, other silicon stacks are turned off in reverse; and so on, the nth ultra-high voltage single pulse The pulse 11 is delivered to the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com