Laterally diffused metal oxide semiconductor (LDMOS) structure for protecting channel district by utilizing polysilicon field polar plate

A channel region and field plate technology, used in electrical components, circuits, semiconductor devices, etc., can solve the problems of limiting the maximum operating voltage of the device and low breakdown voltage, improving the distribution of the surface electric field and increasing the breakdown voltage. , the effect of increasing the maximum voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

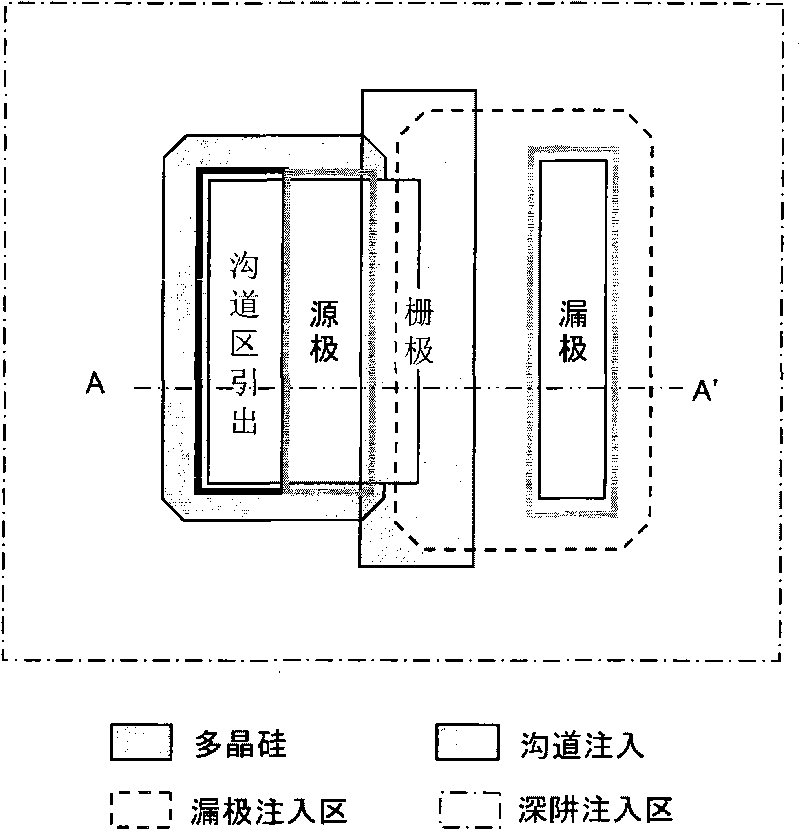

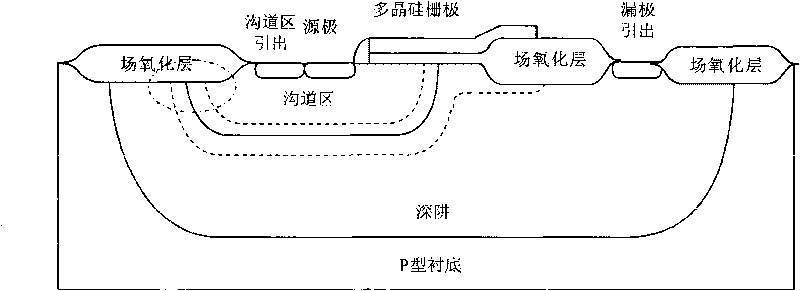

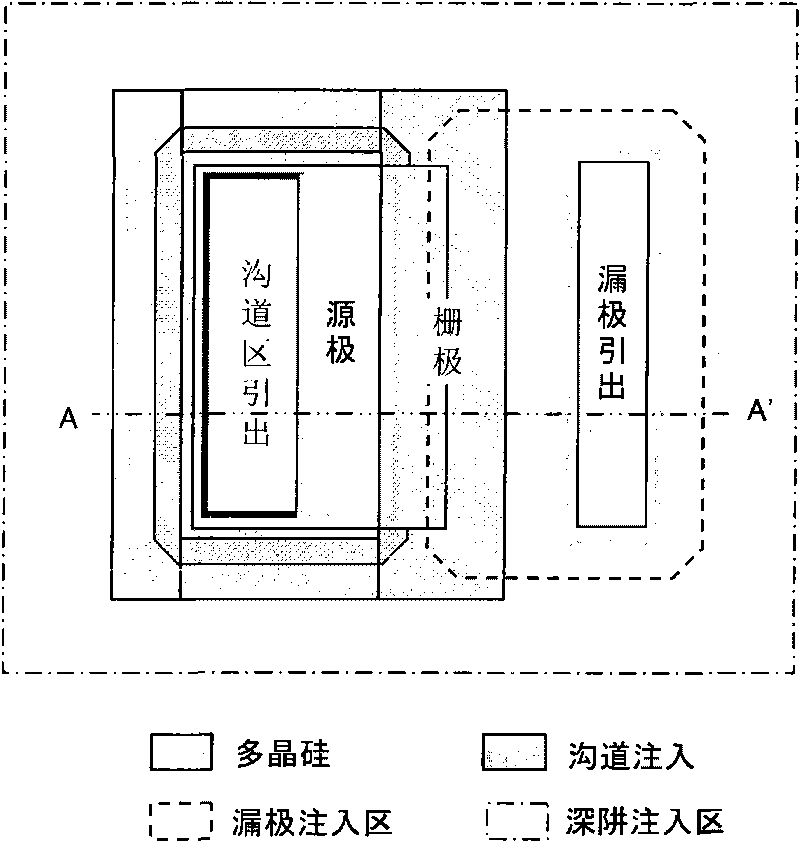

[0012] Such as image 3 with Figure 4 As shown, in the present invention, the LDMOS structure includes: a deep well, a source, a drain, a gate and a channel region, wherein the source, a drain, a gate and a channel region are all in the deep well, and the source The electrode and channel regions are on one side of the gate, and the drain is on the other side of the gate. The source, deep well, and drain are of the same doping type, and the source, deep well, and channel region are of opposite doping types. A polysilicon field plate is provided above the channel region and the edge of the deep well, or a polysilicon field plate is added above the PN junction edge of the channel region and the drain to deplete the drain surface under the polysilicon, thereby improving the surface electric field. The distribution increases the breakdown volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com