Intelligent numerical control welding machine

A welding machine and intelligent technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high labor intensity and photoelectricity affecting the health of workers, and achieve a high degree of automation, protection of health, and novel structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

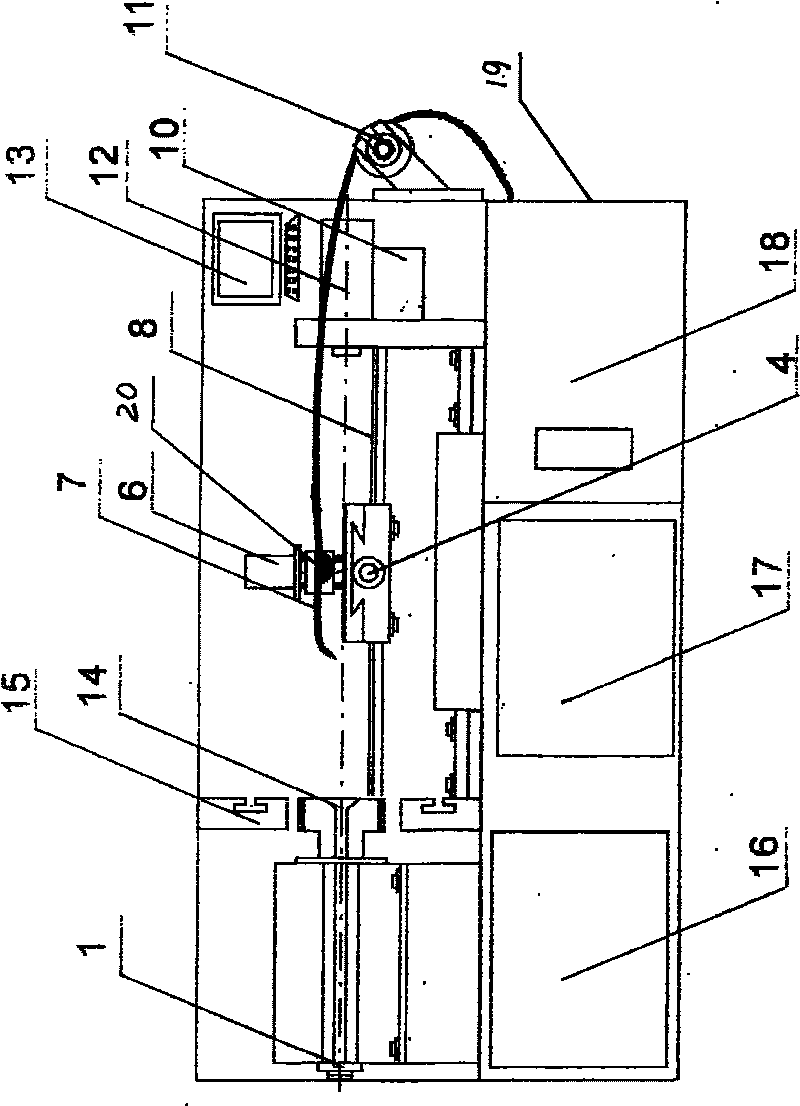

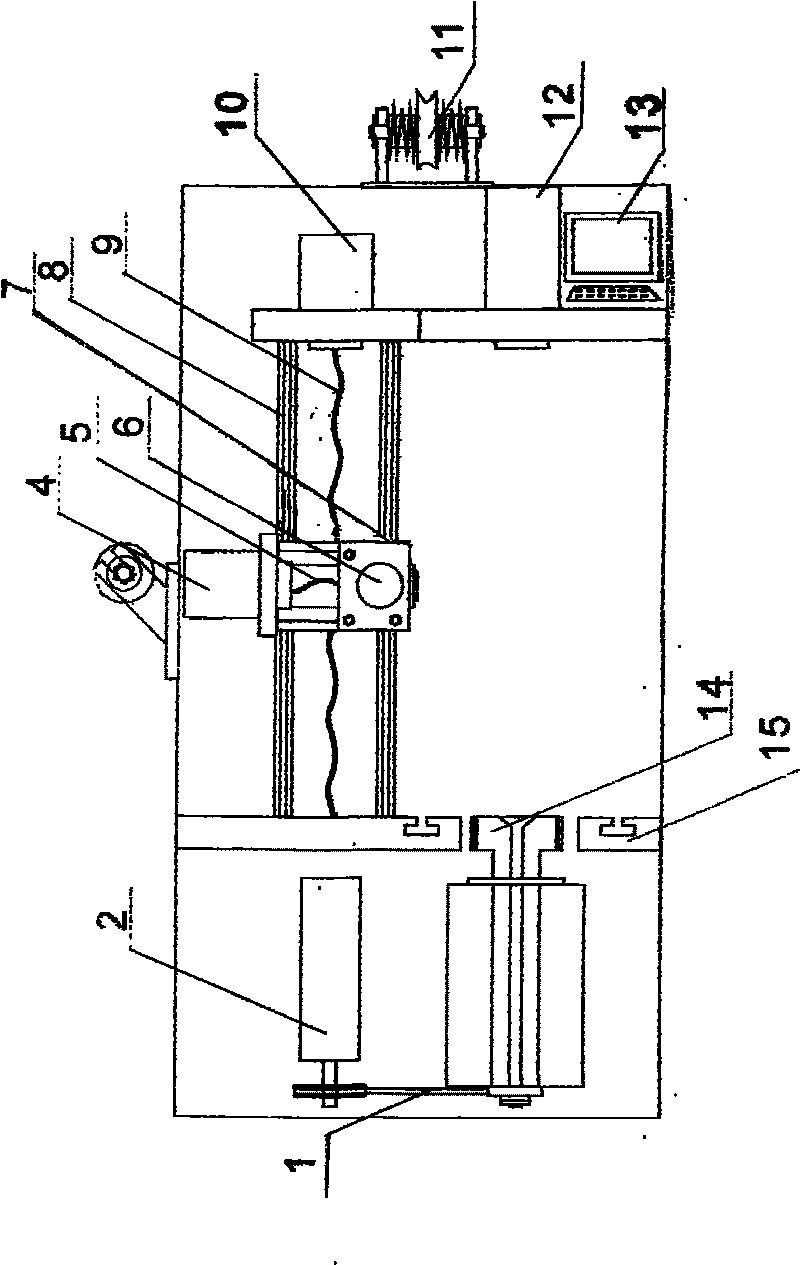

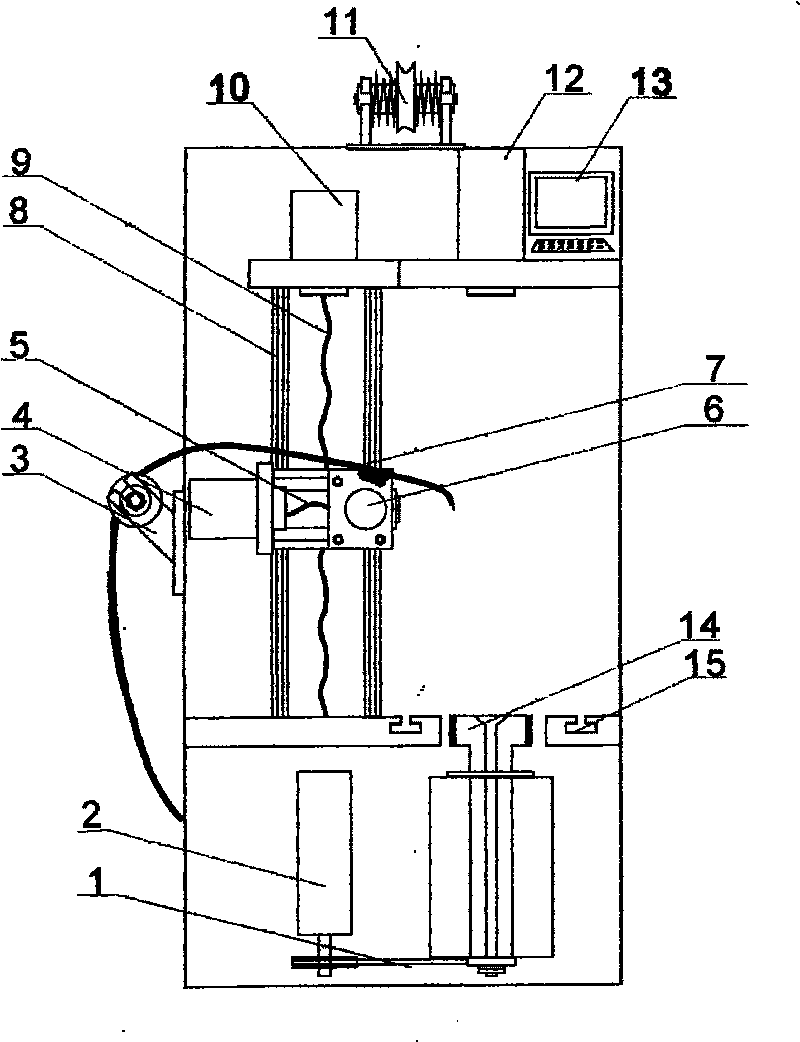

[0011] As shown in 1 and 2, the present invention is a horizontal structure, and mainly consists of a frame 19 of an intelligent numerical control welding machine and a welding machine 16 arranged on the frame 19. The frame 19 adopts a closed design, and there are activities in the middle. sliding door. Described frame 19 is provided with running rail 8, is provided with welding torch fixture 20 on the running track 8, and welding torch 7 is housed on the welding torch fixture 20, and welding torch fixture 20 is driven by the longitudinal drive motor 10 that is located on the frame 19 Driven by the drive mechanism 9, it reciprocates left and right on the running track 8. A transverse drive motor 4 is also provided on the welding torch fixture 20 to control the front and rear strokes of the welding torch 7. The welding torch fixture 20 is also provided with an operable welding torch 7 up and down. Movable drive motor 6, drive motor 6 drives welding torch by drive mechanism 5 up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com