Dustproof material-guiding skirt board for belt conveyor

A belt conveyor, dust-proof technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of loss of confidence in the dust-proof system, waste of investment, etc., and achieve the effect of solving the problem of dust-proof conveying of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

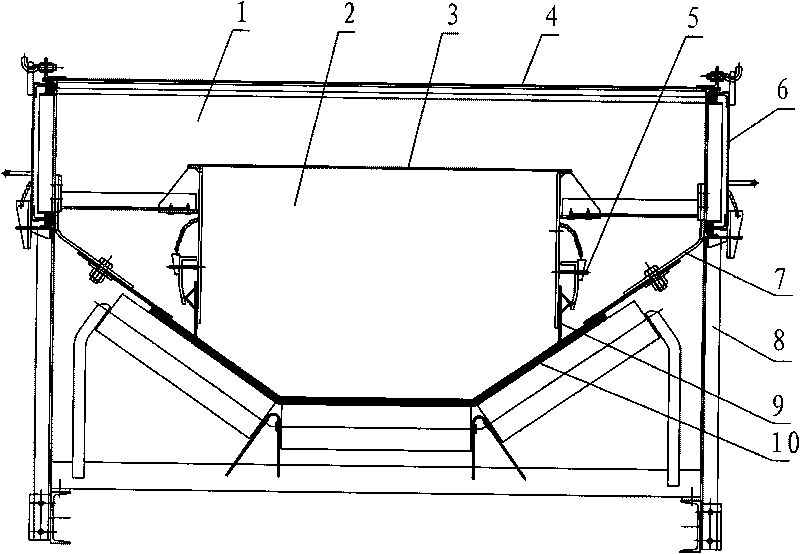

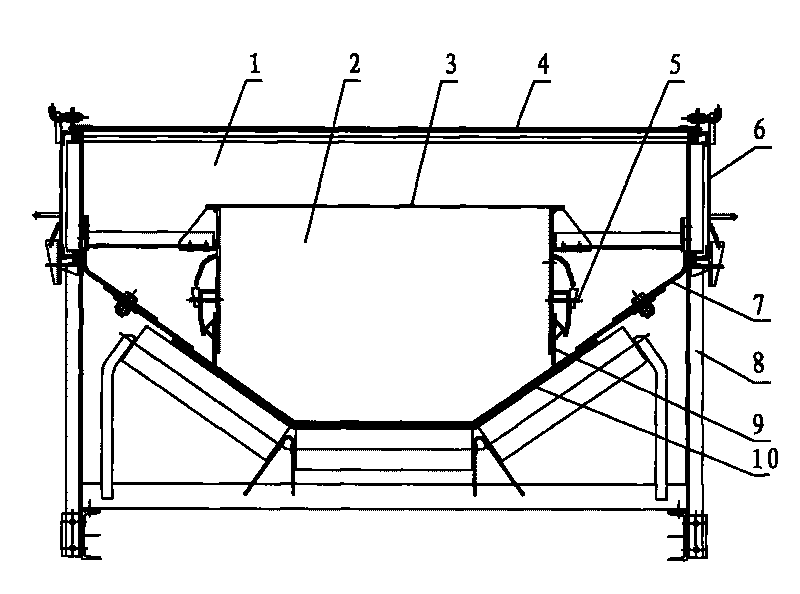

[0009] The material guide skirt is composed of a cover body 3, an upper cover plate 4, a pressing piece 5, a side cover plate 6, a baffle plate 7, a column 8, a rubber plate 9 and the like. Cover body 3 is established on adhesive tape 10, rubber plate 9 is established between adhesive tape 10 and cover body 3 and rubber plate 9 is fixed on cover body 3 with pressing piece 5, it is characterized in that baffle plate 7 is set on both sides of adhesive tape 10, can The closed cavity 2 formed between the open side cover 6, the upper cover 4 and the column 8, the cover body 3, the rubber plate 9 and the adhesive tape 10 is a positive pressure cavity, the upper cover 4, the openable side cover 6, The closed cavity 1 formed between the baffle plate 7, the adhesive tape 10 and the cover body 3 is a negative pressure cavity, and the dust removal pipe is connected with the negative pressure cavity, and directly sucks the airflow with a low dust concentration after preliminary filtration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com