Method for preparing crystalline-state mesoporous CoFe204 with large specific surface area

A technology with large specific surface area and crystalline state, which is applied in the field of preparation of mesoporous CoFe2O4, can solve the problem of few binary or multi-component mesoporous metal oxides, achieve simple impregnation method and strategy, reduce pore structure collapse, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Mesoporous CoFe 2 o 4 - Preparation of SBA

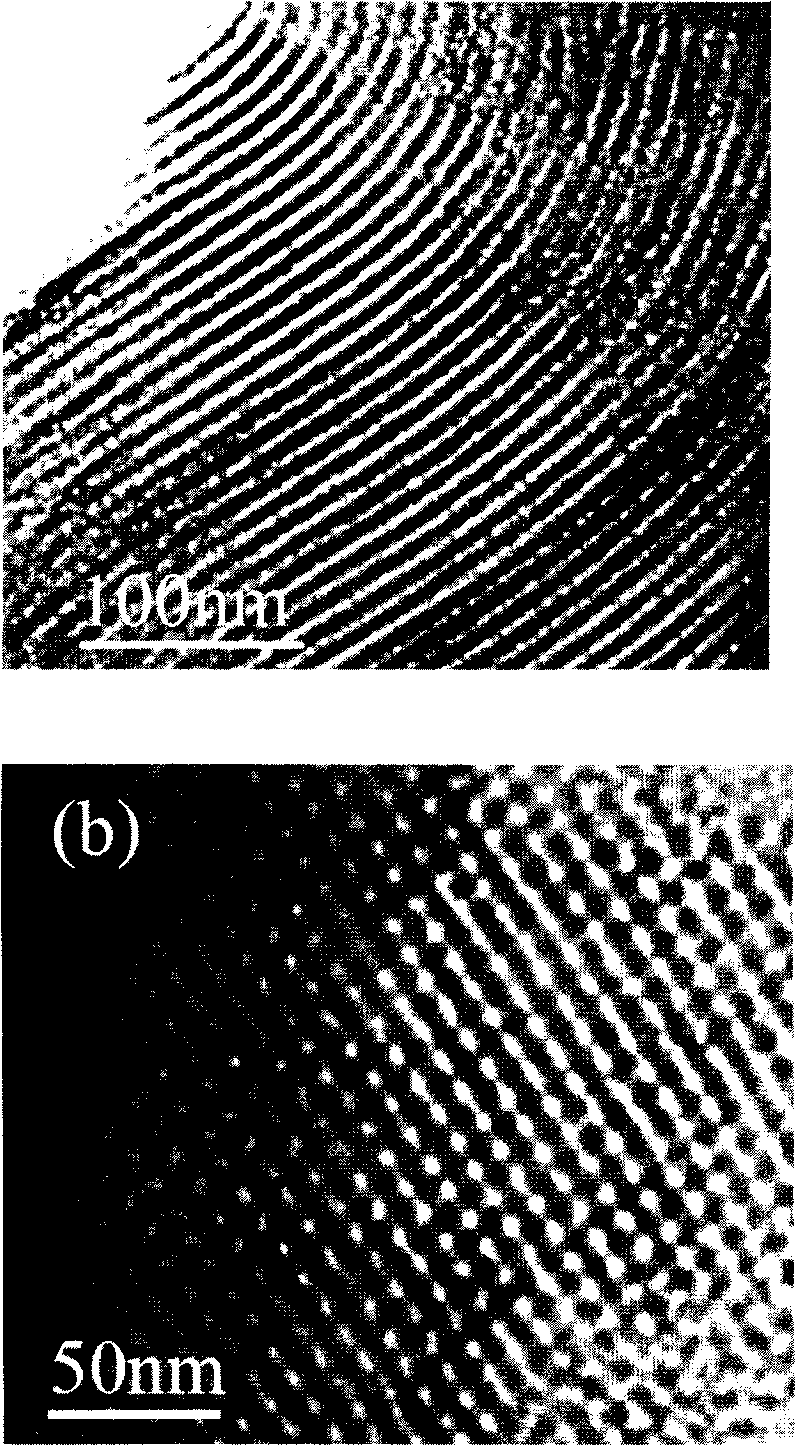

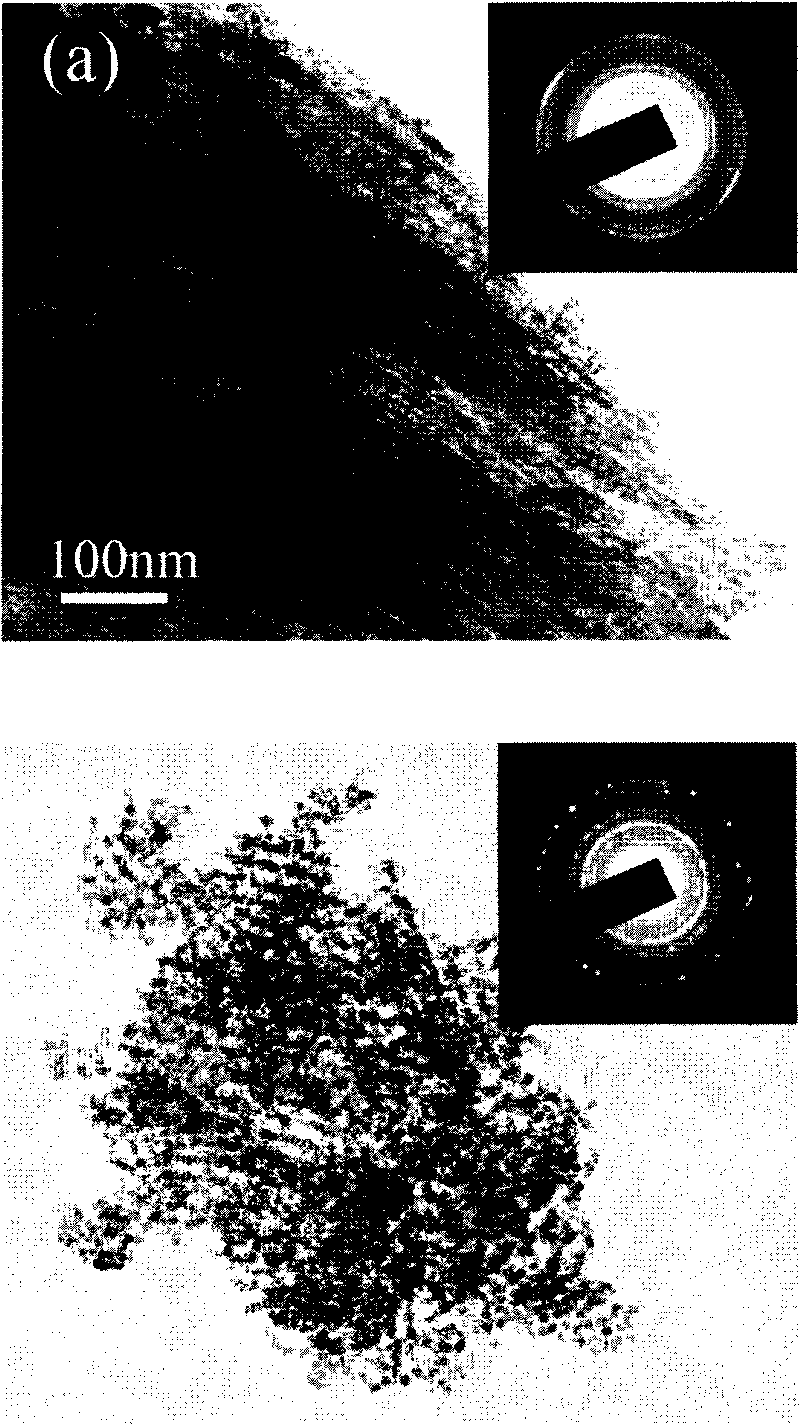

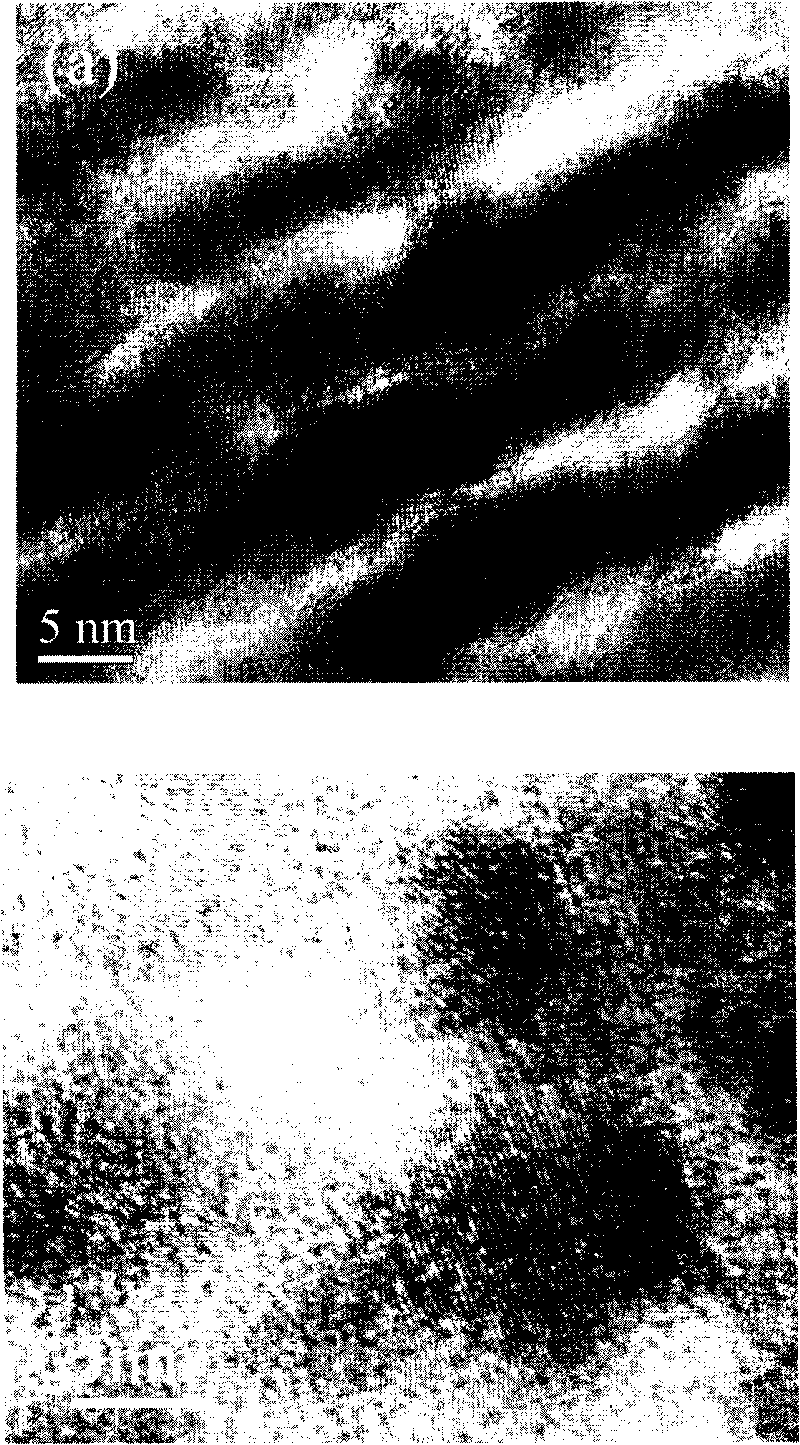

[0027] 1) According to the literature (Zhao, D.Y.et al..Science, 1998, 279:548), first prepare the mesoporous silica template SBA-15, the process is: in a 40°C constant temperature water bath, 2g triblock copolymer P123 ((EO) 20 (PO) 70 (EO) 20 ) was added to 80mL 2M HCl, and continued strong magnetic stirring until completely dissolved, then added 4.25g ethyl orthosilicate, and continued to stir for 24h. Transfer the resulting mixture to an autoclave, seal it and put it in a thermostat at 100°C for hydrothermal treatment for 24 hours. After filtering and washing, dry it at 80-100°C for 24 hours, and then dry it at 1°C / min under air atmosphere. Raise the temperature to 500°C and keep it at this temperature for 3-5h to obtain a large specific surface area (580.06m 2 / g), large pore volume (1.0193m 3 / g) two-dimensional hexagonal mesoporous silica powder SBA-15. From the TEM images ( figure 1 (a)) It can be ...

Embodiment 2

[0032] Example 2: Mesoporous CoFe 2 o 4 - Preparation of KIT

[0033]1) According to the literature (Kim, T.W.et al.J.Am.Chem.Soc., 2005, 127, 7601), the mesoporous silica template KIT-6 was first prepared, and the process was as follows: in a constant temperature water bath at 35°C, 4g triblock copolymer P123 ((EO) 20 (PO) 70 (EO) 20 ) was added to a solution of 144g distilled water and 7.73g 37wt% HCl, completely dissolved under continuous strong magnetic stirring, then 4.0g n-butanol was added, after stirring for 1h, 8.6g ethyl orthosilicate was added, and stirring was continued for 24h. Transfer the resulting mixture to an autoclave, seal it and place it in a thermostat at 100°C for hydrothermal treatment for 24 hours, filter and dry at 100°C for 24 hours, wash with distilled water and acidified ethanol, and then place it in an air atmosphere at 1°C Raise the temperature to 550°C at the rate of / min, and keep it at this temperature for 3-5h, that is, a large specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com