Stainless steel strip bell type annealing furnace

A bell-type annealing furnace, stainless steel technology, applied in bell-type furnaces, furnaces, furnace types and other directions, can solve the problems affecting the quality of stainless steel strips, surface oxidation of stainless steel strips, uneven annealing temperature, etc., to achieve consistent mechanical properties The effect of ensuring stability, sufficient heat convection and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

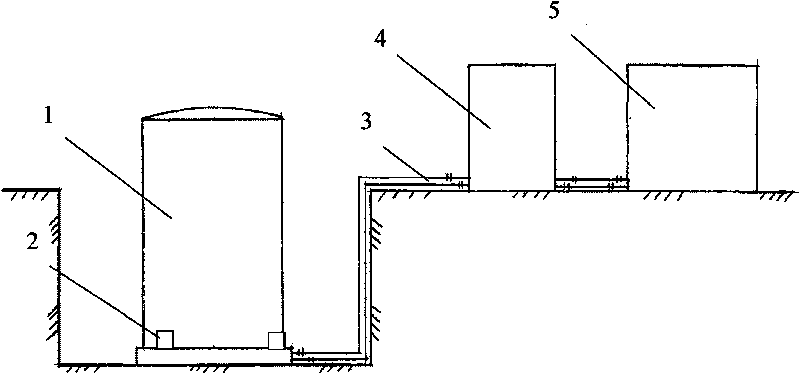

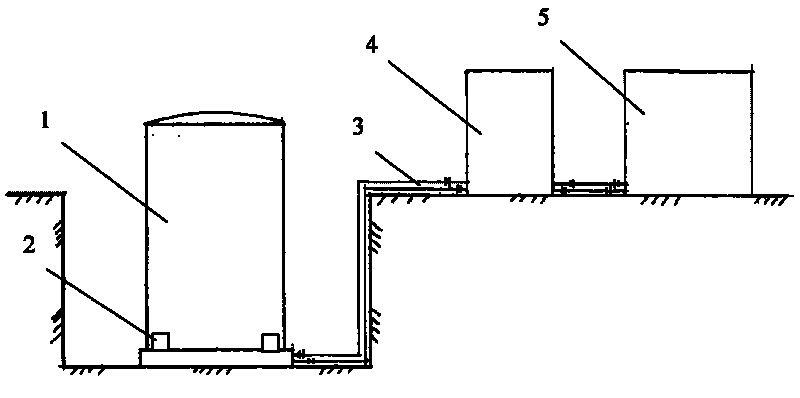

[0008] figure 1 It is a schematic diagram of the overall structure of a specific embodiment of the present invention, combined below figure 1 The embodiments of the present invention are introduced.

[0009] Such as figure 1 As shown, the stainless steel bell-type annealing furnace provided by the embodiment of the present invention comprises a furnace body (1), the bottom of the furnace body (1) is provided with a high-speed convection fan (2), and the furnace body (1) is passed through a conveying pipe (3) Connect the ammonia decomposition gas generator (4), and the ammonia decomposition gas generator (4) is connected to the ammonia decomposition generation controller (5).

[0010] The stainless steel belt bell-type annealing furnace provided by the embodiment of the present invention uses a delivery pipe to transport the ammonia decomposition gas generated by the ammonia decomposition gas generator to the furnace body, so that the ammonia decomposition gas is used as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com