Automatic horizontal silicon substrate film producing device

A silicon-based thin film and production device technology, applied in gaseous chemical plating, coating, metal material coating process, etc., can solve problems such as loss, non-alternative use, production process interruption, etc., and achieve fast heating speed and uniform heating , the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

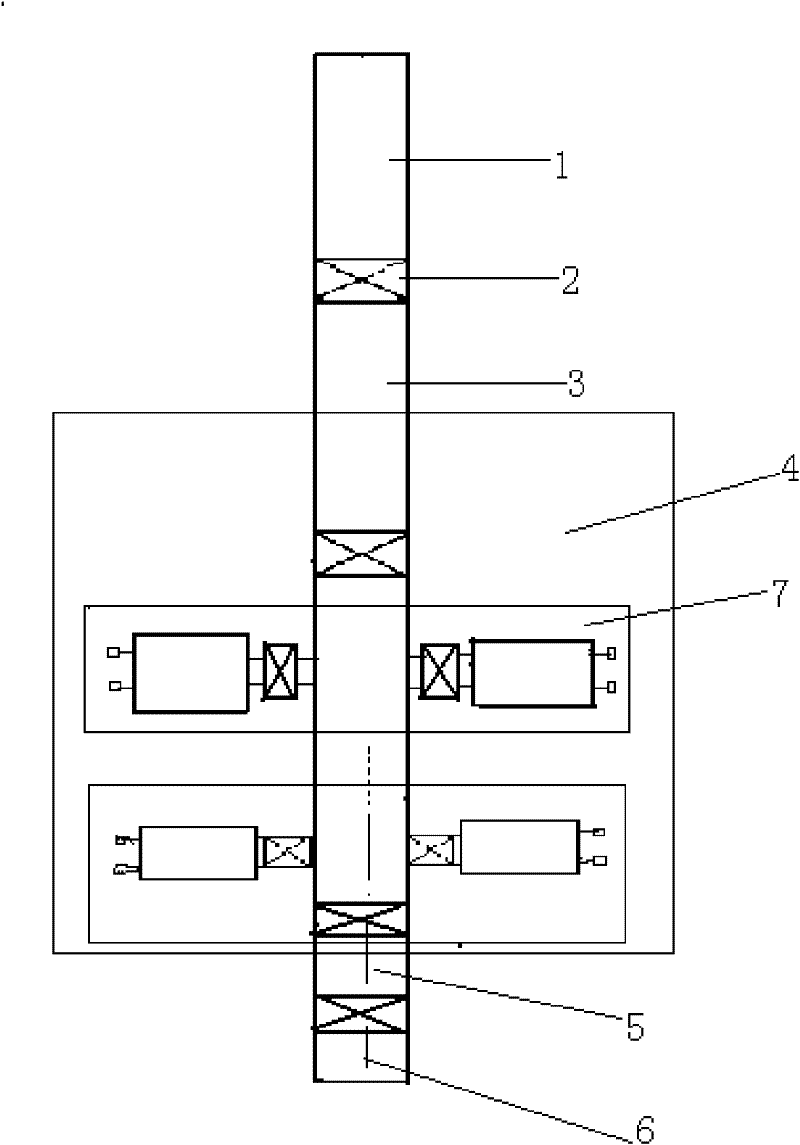

[0027] An automatic horizontal silicon-based film production device is characterized in that it consists of a heating section, a vacuum transition section 1, a deposition section, a vacuum transition section 2, and a cooling section. Automatic gate valves are installed between the working chambers, and the heating section and The cooling section is a non-vacuum section.

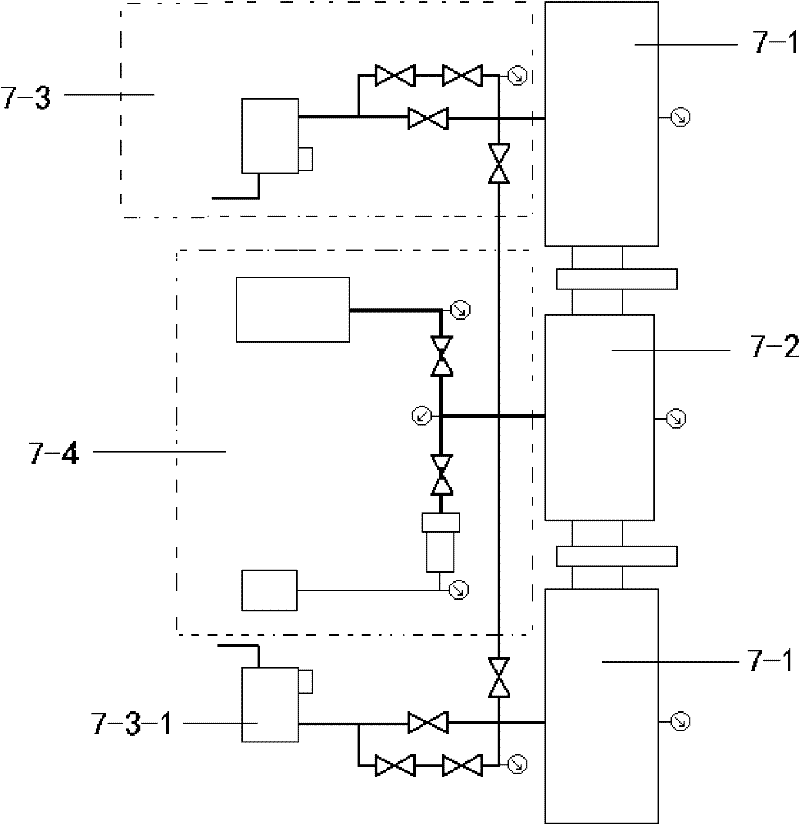

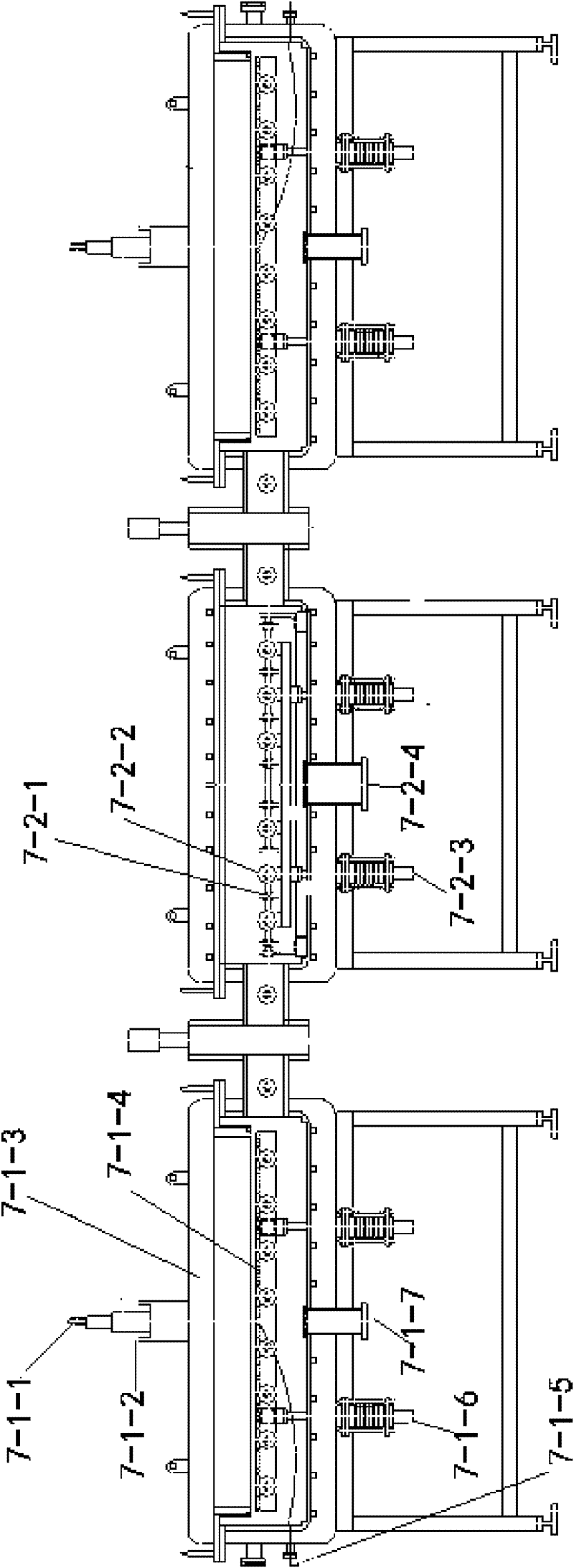

[0028] In the present invention, the deposition section is composed of at least two deposition modules, and each deposition module is composed of a deposition chamber, a vacuum transition chamber, a transmission device, a position measuring device, a vacuum obtaining device, a gas distribution device and an exhaust device, and the deposition chamber is distributed in On both sides of the vacuum transition chamber, each deposition chamber is connected to a process dry pump. The deposition chamber and the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com