Wind turbine and method of assembling the same

A technology of internal gear and holding device, which is applied to wind turbines, wind turbine components, wind turbines that are consistent with the wind direction, etc., can solve problems such as deteriorating sliding surfaces and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

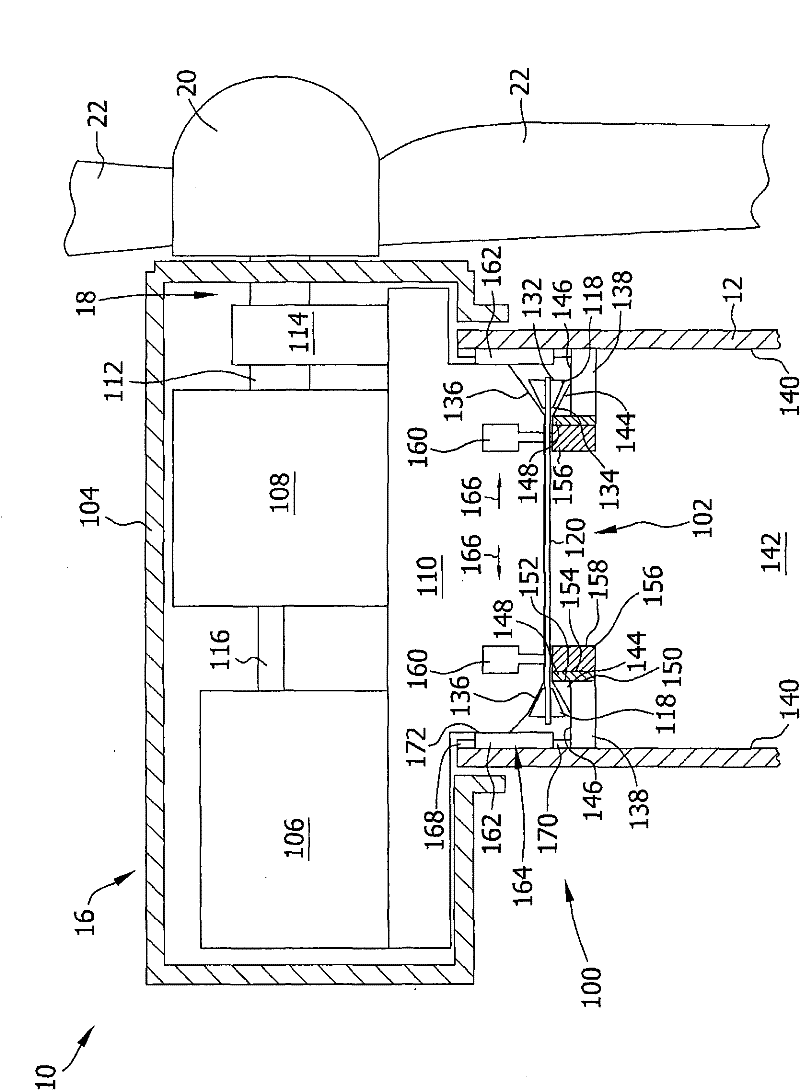

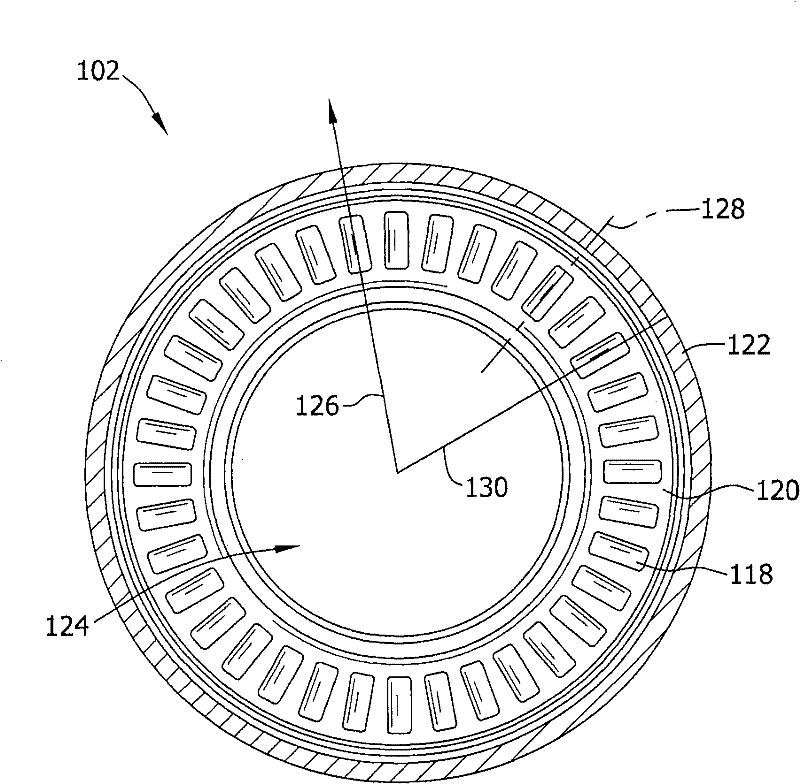

[0014] The embodiments described herein can be used with a bucket-type yaw system, where the bending moment and / or torque are laterally supported, and the weight of the housing is supported by flat or tapered bearings or slip rings ( For example, open needle slew bearing (open needle slew bearing) support. This bearing structure does not require high-precision machining and / or manufacturing of the yaw brake and / or bearing. In addition, the embodiments described herein include at least one sliding pad that is in contact with the base of the outer cover and includes a low-friction material. This sliding pad supports the outer cover laterally while allowing the outer cover to rotate relative to the tower.

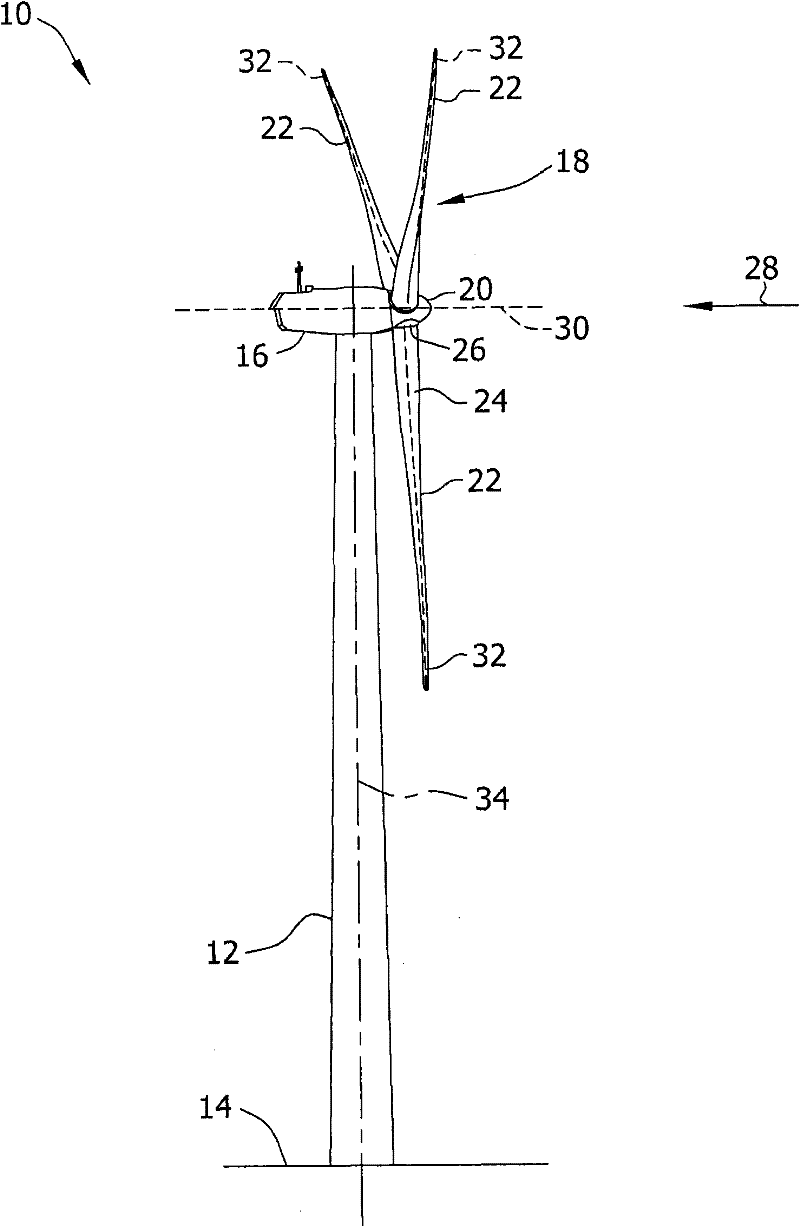

[0015] figure 1 This is a vertical projection view of an exemplary wind turbine 10 from the side. In this exemplary embodiment, wind turbine 10 is a near horizontal axis wind turbine. In another embodiment, the wind turbine 10 may have an upwardly inclined angle (not shown) va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com