Fingertip seal structure and back baffle plate thereof

A fingertip seal and tailgate technology, which is applied to engine seals, engine components, mechanical equipment, etc., can solve problems such as loss of sealing performance, and achieve the effects of good sealing performance, great economic benefits, and low leakage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

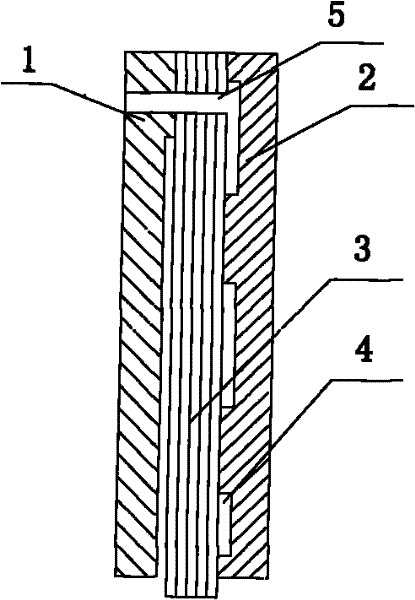

[0028] see figure 1 , which is a structural schematic diagram of a preferred embodiment of the fingertip sealing structure of the present invention. In this embodiment, the fingertip sealing structure is composed of a front baffle 1, a rear baffle 2 and five layers of fingertip sheets 3 arranged between them, wherein the front baffle 1, the rear baffle 2 And the fingertip piece 3 is an annular plate structure, connected with each other by riveting or welding.

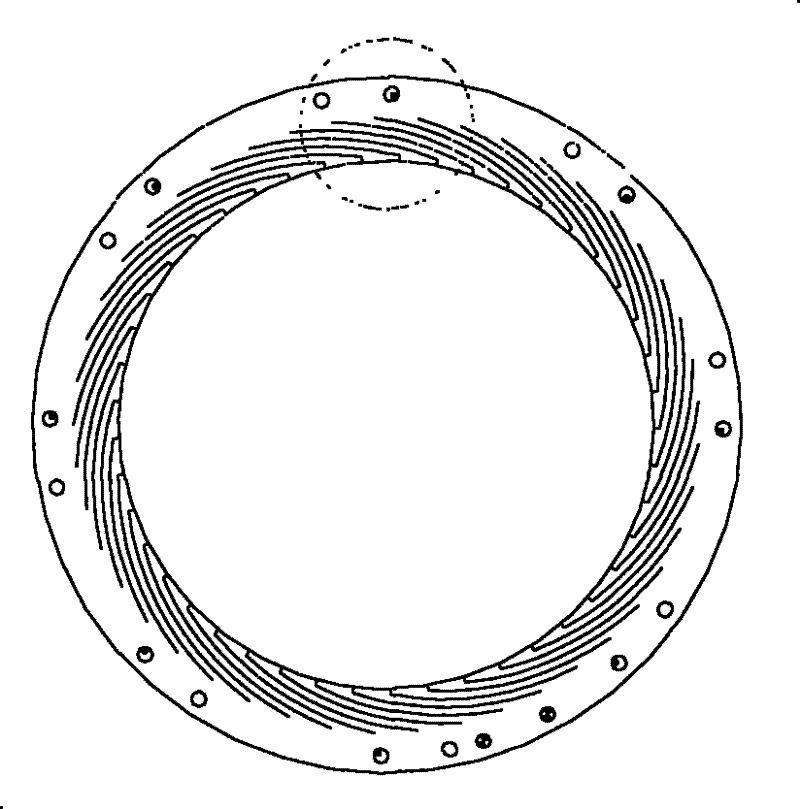

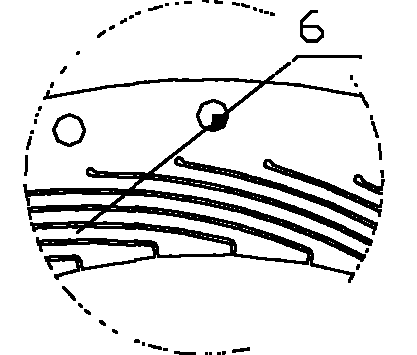

[0029] Please also see figure 2 and image 3 ,in, figure 2 It is the front view of the fingertip sheet of the fingertip sealing structure of the present invention, image 3 yes figure 2 A partial enlargement of the . The inner diameter of the fingertip sheet 3 is provided with a finger body with an involute gap, and two adjacent finger bodies near the inner diameter form a sealing shoe. At the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com