Method for confirming vacuum grease adding amount in spatial mechanism bearing

A technology of vacuum grease and bearings, which is applied in the direction of mechanical bearing testing, dosing device, engine lubrication, etc., can solve the problem that the filling amount of bearing vacuum grease is difficult to quantify, and there is no corresponding standard for filling amount, filling method and operation specification. Lack of verification methods for the vacuum grease filling process, etc., to achieve good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

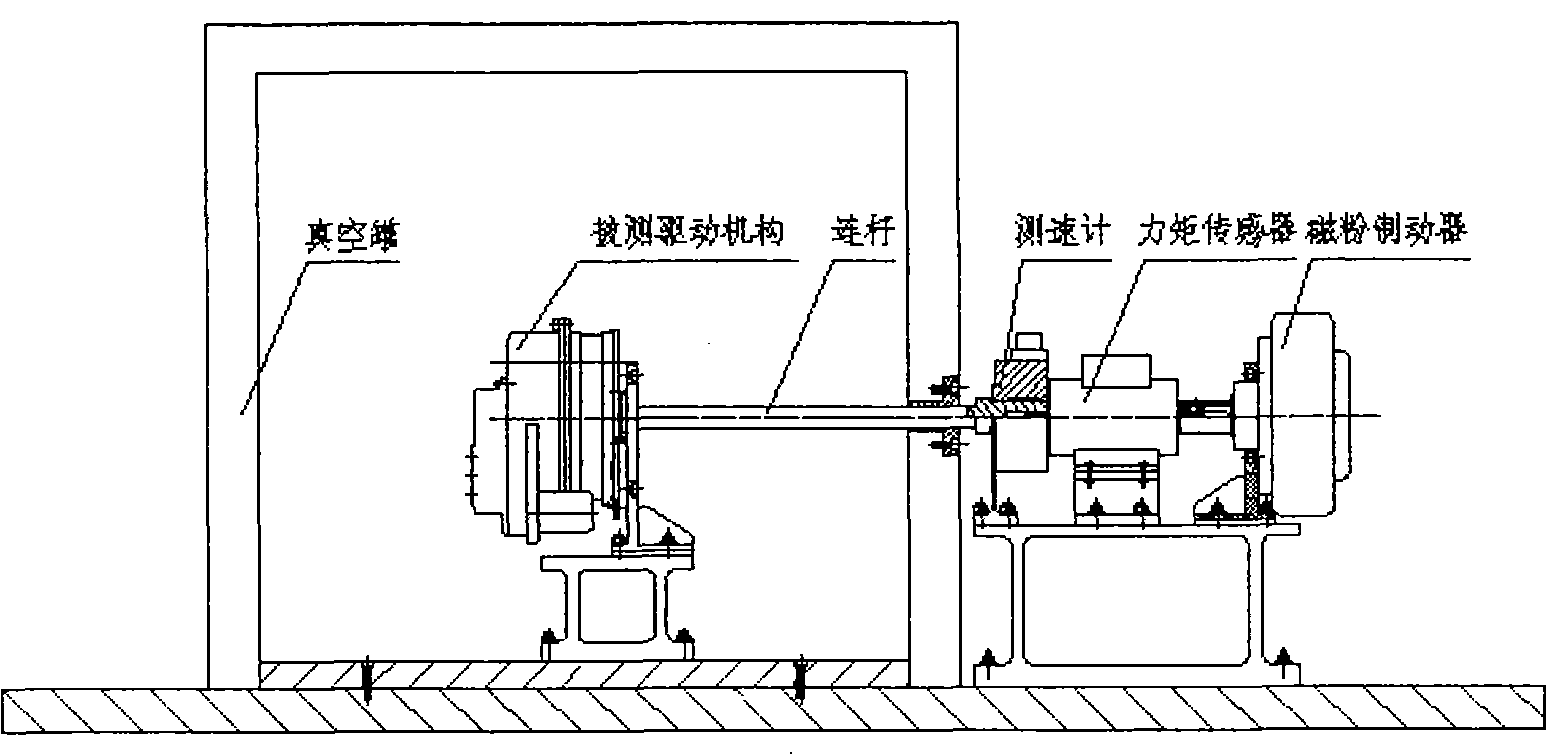

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

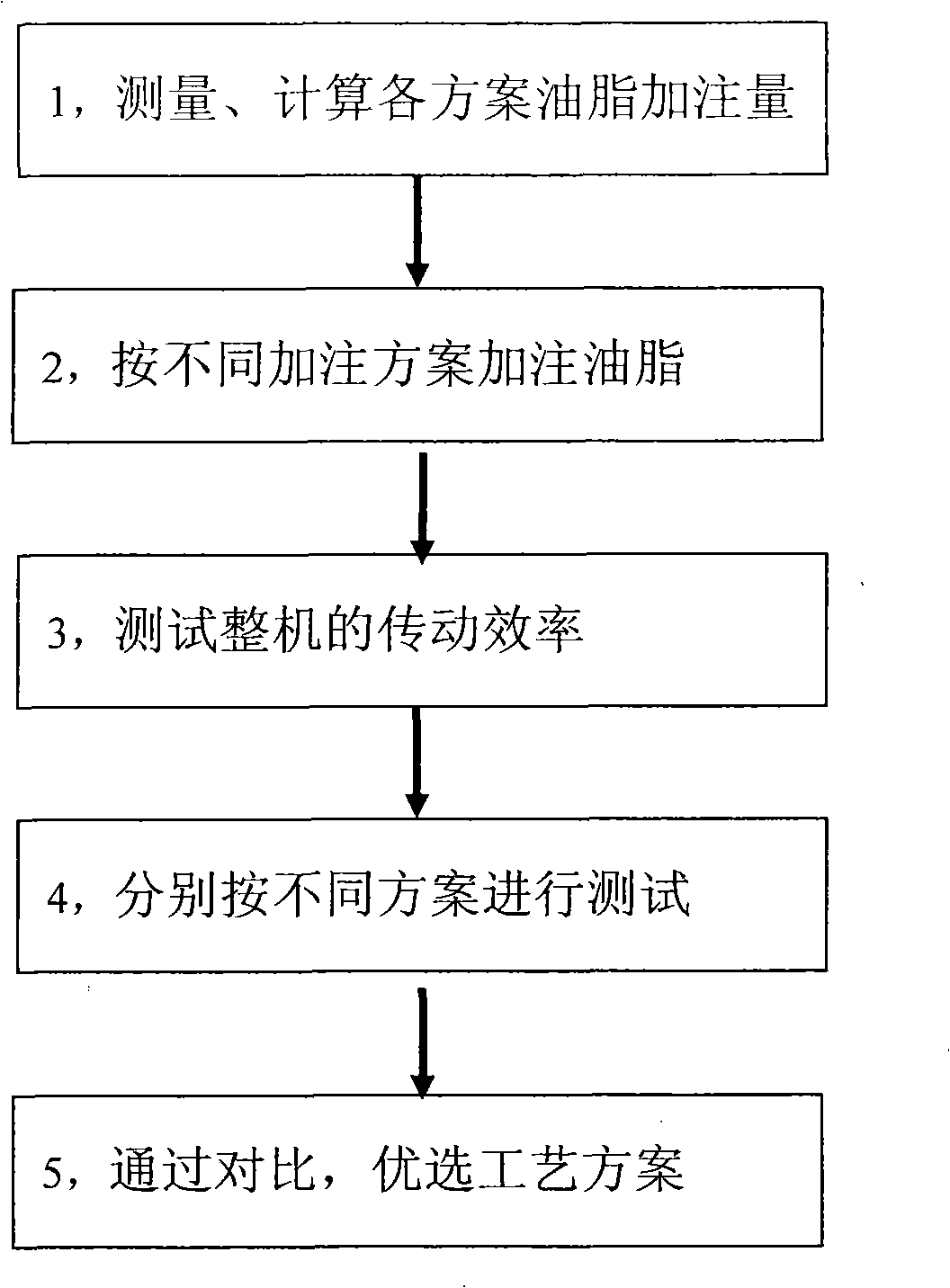

[0021] The accompanying drawing is a step diagram of a method for determining the filling amount of bearing vacuum grease, including the following steps:

[0022] 1) Measure and calculate the amount of grease filling for different schemes.

[0023] Use the "equal volume method" to accurately measure the remaining volume between the inner and outer rings of the bearing. Fill the space between the inner and outer rings of the bearing with water and measure the volume of the water with a precision measuring instrument to obtain the remaining volume between the inner and outer rings of the bearing. Then, according to the density of the selected vacuum grease, calculate the mass of grease that should be filled in different schemes, and use precision weighing equipment to weigh out the corresponding grease.

[0024] 2) Add grease according to diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com