Direct backlight device

A backlight device, a direct-type technology, applied to lighting devices, fixed lighting devices, lighting device components, etc., can solve problems such as insufficient luminance uniformity, achieve suppression of luminance unevenness, and efficient use of high light beams High efficiency and brightness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Resin having an alicyclic structure as a transparent resin [Nippon Zeon Co., Ltd. (ZEON Corporation of Japan), Zeonora 1060R (ZEONER 1060R), water absorption 0.01%] 99.7 parts, and polysiloxane as a light diffusing agent Microparticles [GE Toshiba Silicon Co., Ltd. (GE Toshiba Silicon Company), Tospearl 120 (Tospearl 120)] composed of cross-linked polymers were mixed in 0.3 parts, kneaded with a two-screw extruder, and formed as a tow Shape extruded, and cut with a pelletizing machine (pelletizing machine), thereby manufacturing pellets (pellets) for light diffusion plates. From these pellets for a light diffusion plate, a test plate having a thickness of 2 mm and a thickness of 100 mm×50 mm with both sides smooth was molded using an extrusion molding machine [die bonding force: 1000 kN]. The total light transmittance and haze of this test plate were measured using the integrating sphere method color difference nephelometer in accordance with JIS K7361-1 and JIS K7136. ...

Embodiment 2

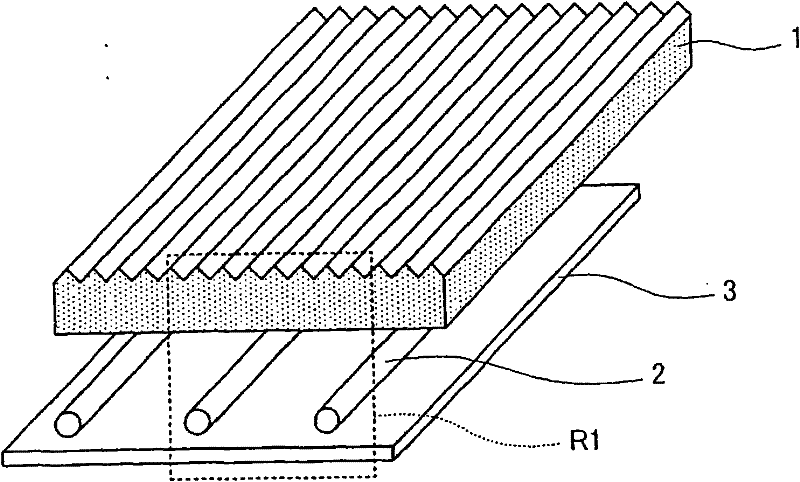

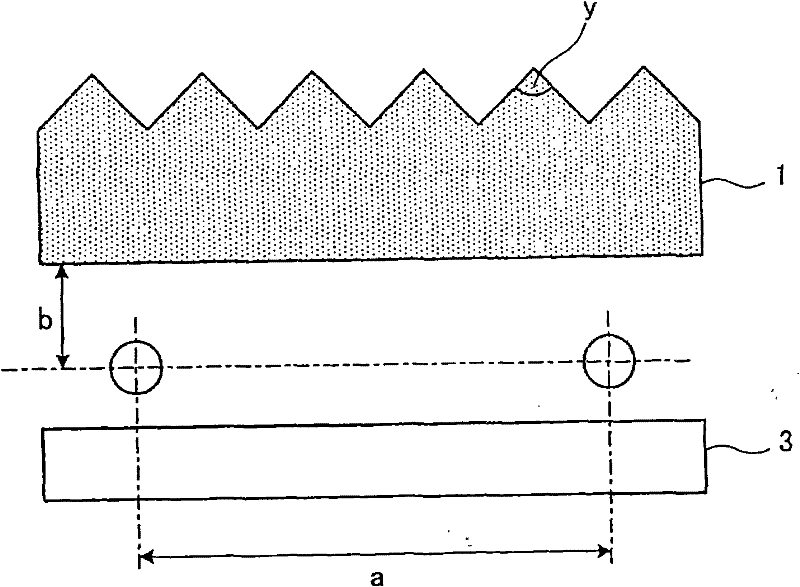

[0122] A reflective sheet (manufactured by Tsujiden Co., Ltd., RF188 (RF188 manufactured by TSUJIDEN)) was pasted on the inner surface of a milky white plastic case with an inner length of 300 mm, an inner width of 240 mm, and a depth of 11 mm. As a reflector, the distance from the bottom of the reflector was 4 mm. The distance a between the centers of the cold-cathode tubes was 25 mm, and eight cold-cathode tubes with a diameter of 4 mm and a length of 360 mm were arranged. ). For the backlight designed in this way, since the distance b between the center of the cold-cathode tube and the side of the cold-cathode tube of the light diffusion plate is 7 mm, the values of a and b are substituted into (Formula 1), and the preferred range of the prism apex angle y is found to be 37.4 <y<120.4.

[0123] Here, the metal part of the mold is cut to prepare a mold that forms prism strips in a cross-sectional shape of connected isosceles triangles with an apex angle of 95° parallel to...

Embodiment 3

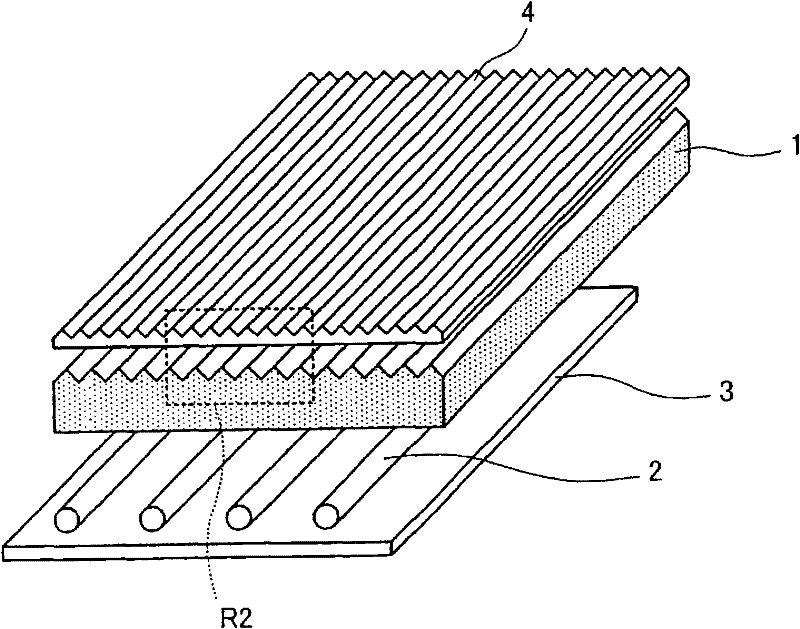

[0126] In this embodiment, a prism sheet is used in place of a reflective polarizer utilizing birefringence in such a manner that the long direction of the prism row is 90° from the cold cathode tube and is located on the side far from the light diffusion plate. Setting was carried out in the same manner as in Example 1, and a front-type backlight device 3 was fabricated and evaluated. Its average luminance is 3639cd / m 2 , the luminance uniformity is 0.4. The results are shown in Table 1. In addition, the luminance uniformity from the oblique direction was 0.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com