Method for repairing liquid crystal display panel using polarized light

A liquid crystal display panel and repair method technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of inability to obtain efficiency and difficulty in linearly polarized light passing through the liquid crystal display panel polarizer uniformly, so as to improve the success rate of repair, Eliminates the effect of light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

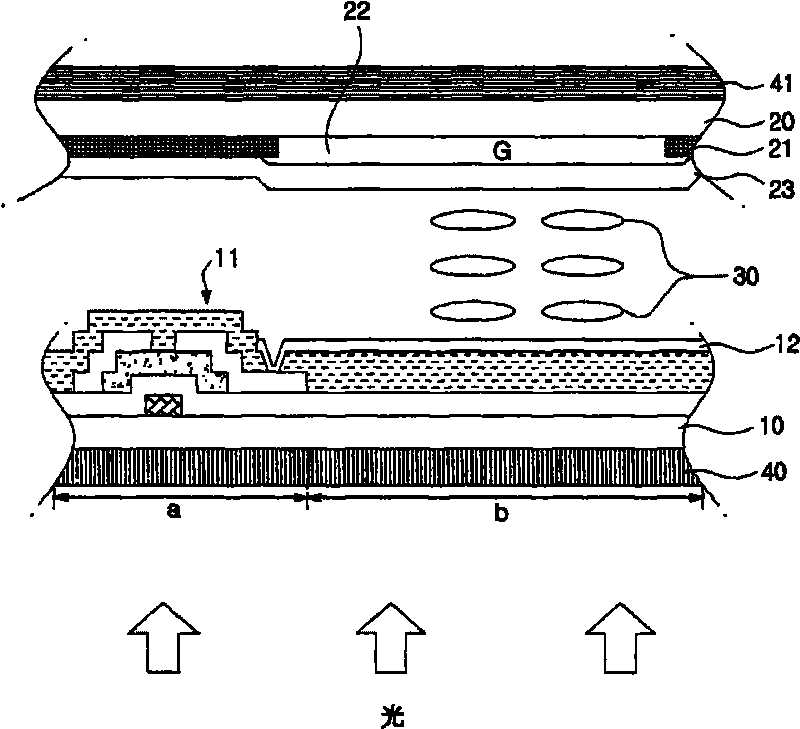

[0067] Figure 7 It is a schematic diagram showing the process of repairing a defective pixel of a liquid crystal display panel according to Experimental Example 1 of the present invention.

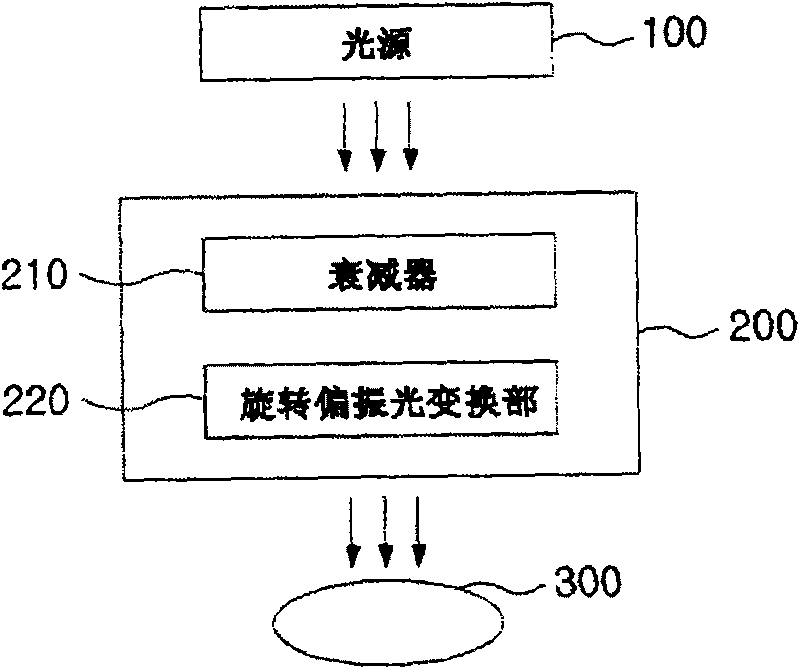

[0068] Such as Figure 7 Shown, in Experimental Example 1 of the present invention, with reference to image 3 The described embodiment of the present invention similarly uses a restoration device including a light source 100 , a light transmission unit 200 , and a light collection unit 300 .

[0069] First, a CW laser having a wavelength of 445 nm was used as a light source, and the laser intensity of the CW laser was adjusted to 75 mW using the attenuator 210 of the light transmission part 200 .

[0070] Then, the light passing through the attenuator 210 is converted into elliptically polarized light by the 1 / 4 wavelength plate in the polarized light conversion unit 220 .

[0071] Next, after the light is transmitted through the upper polarizer 41 corresponding to the green G pixel a...

experiment example 2

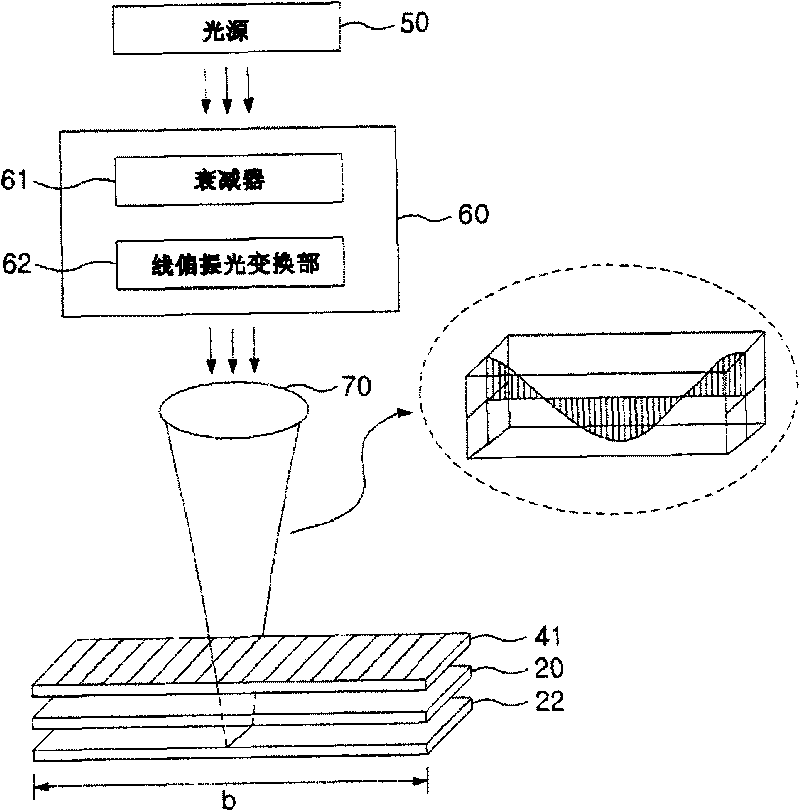

[0073] Figure 8 It is a schematic diagram showing the process of repairing a defective pixel of a liquid crystal display panel according to Experimental Example 2 of the present invention.

[0074] Such as Figure 8 Shown, in Experimental Example 2 of the present invention, with reference to image 3 The described embodiment of the present invention similarly uses a restoration device including a light source 100 , a light transmission unit 200 , and a light collection unit 300 .

[0075] First, a CW laser having a wavelength of 445 nm was used as a light source, and the laser intensity of the CW laser was adjusted to 75 mW using the attenuator 210 of the light transmission part 200 .

[0076] Then, the continuous laser light passing through the attenuator 210 is converted into circularly polarized light by using a 1 / 4 wave plate in the rotating polarization conversion unit 220 .

[0077] Next, after the light is transmitted through the upper polarizer 41 corresponding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com