Defect detection device and method

A defect detection and line defect technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of invisible, unrepairable, large taper angle, etc., to improve accuracy, improve repair success rate, and improve product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

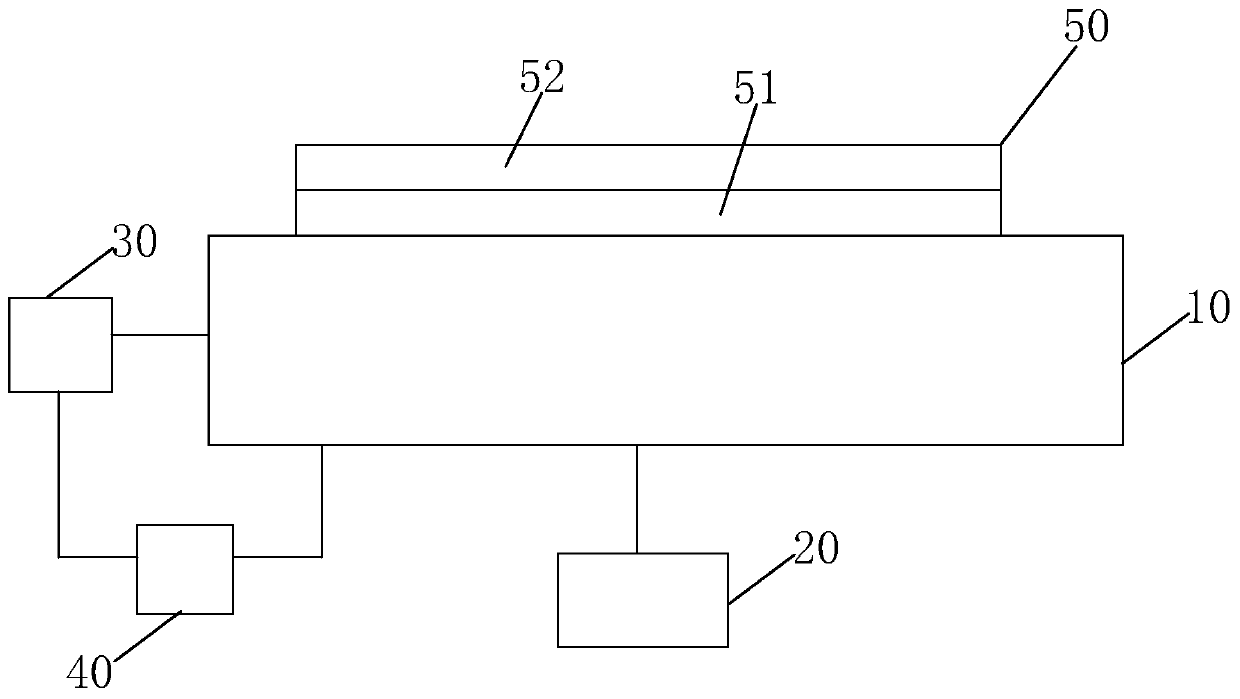

[0037] see figure 1, the present invention provides a defect detection device, comprising: a detection machine 10, a back camera unit 20 connected to the detection machine 10 and located below the detection machine 10, an array connected to the detection machine 10 A testing unit 30 and a processing unit 40 connected to the detection machine 10 and the array testing unit 30;

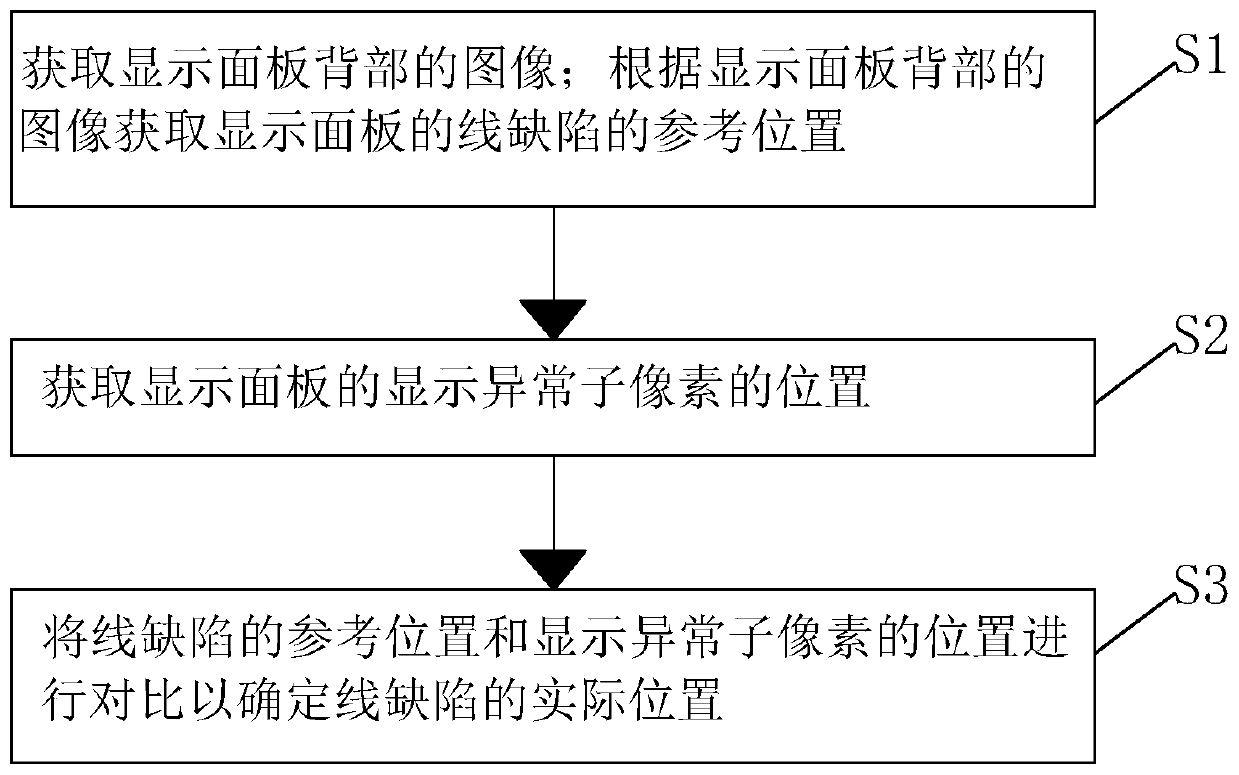

[0038] The back camera unit 20 is used to acquire an image of the back of the display panel 50;

[0039] The detection machine 10 is used to obtain the reference position of the line defect of the display panel 50 according to the image on the back of the display panel 50;

[0040] The array testing unit 30 is used to obtain the position of the sub-pixel displaying an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com