Sensing circuit of capacitance type touch panel

A capacitive touch and sensing circuit technology, applied in electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problem that the difference in voltage change is too small and the circuit cannot calculate the position of the contact point based on it , the difference in the amount of induced charge is too small, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

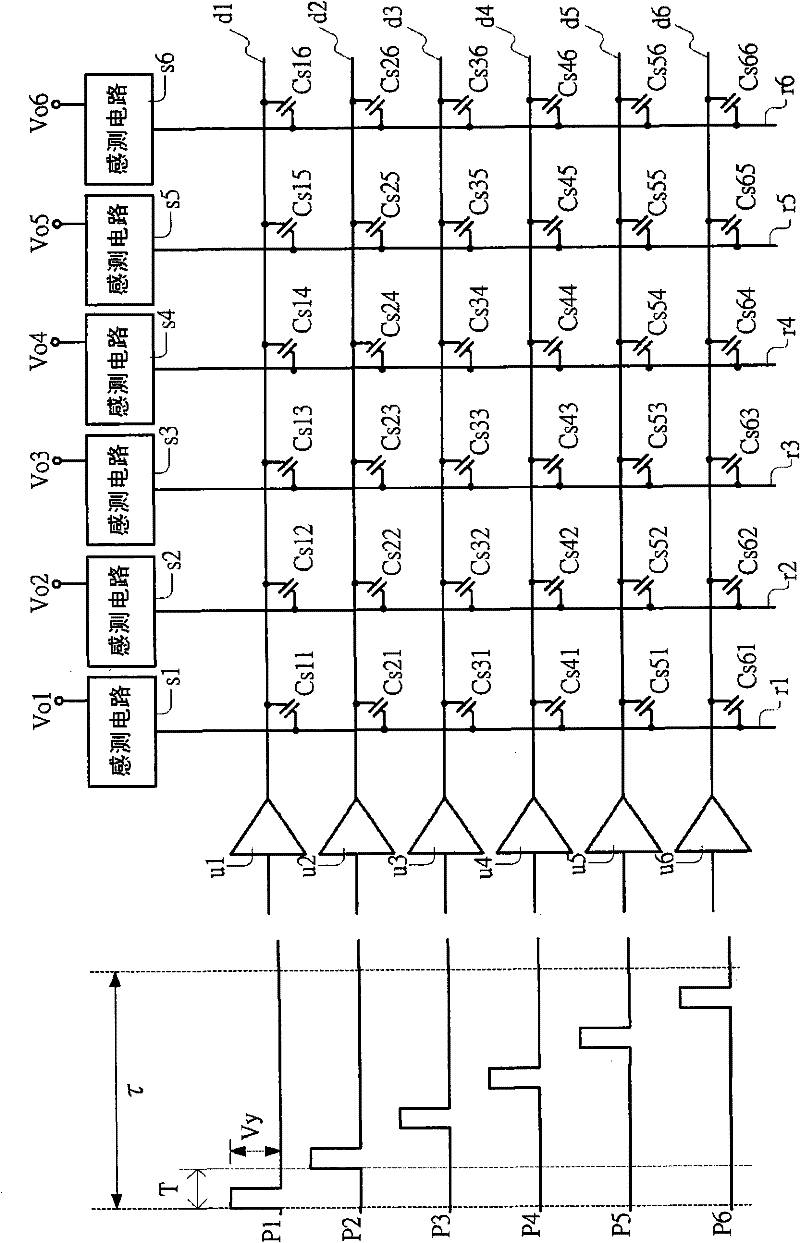

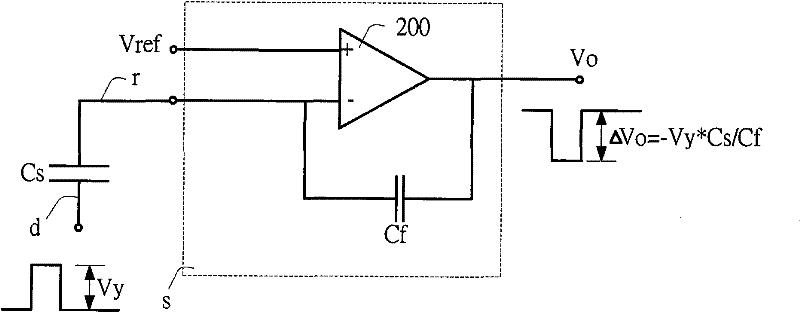

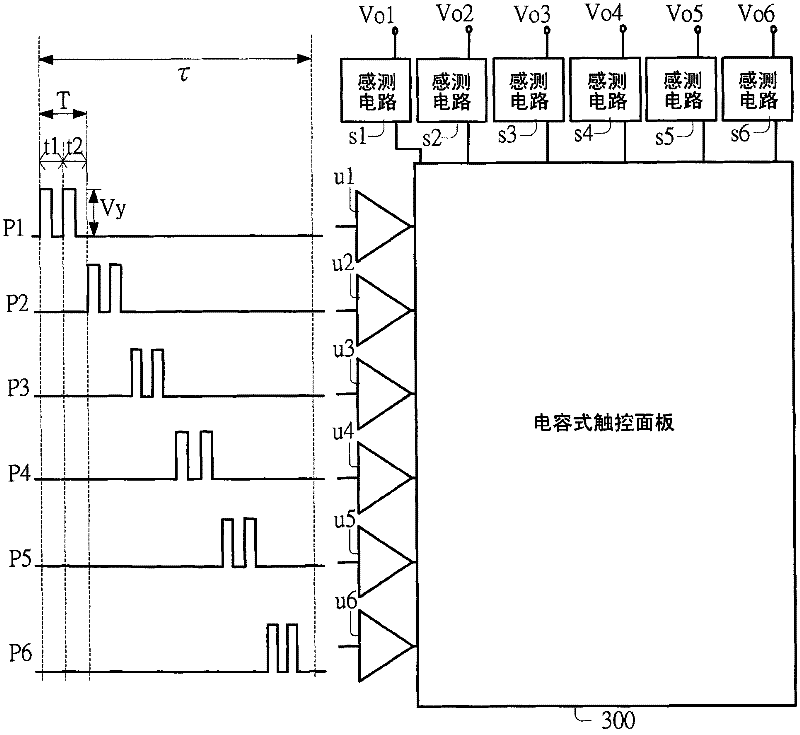

[0033] Please refer to Figure 4A and Figure 4B , which shows the first embodiment of the sensing circuit and its control signal of the present invention. The sensing circuit s includes: an operational amplifier 400, a feedback capacitor Cf, and four switch circuits sw1˜sw4. Moreover, the driving signal P can generate induced charges in the mutual capacitance Cs through the driving electrode d, and transmit to the input terminal of the sensing circuit s through the receiving electrode r.

[0034] Wherein, the input end of the sensing circuit s is connected to the first end of the first switch sw1 (controlled by the first control signal ctr1) and the first end of the second switch sw2 (controlled by the second control signal ctr2), and the first end of the first switch sw1 The two terminals are connected to the third switch sw3 (controlled by the third control signal ctr3) and the first terminal of the feedback capacitor Cf; the negative input terminal (-) of the operational...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com