A kind of preparation technology of non-enzymatic glucose sensing detection system

A detection system, preparation process technology, applied in measurement devices, nanotechnology for materials and surface science, instruments, etc., can solve the problems of enzymes affecting activity, operational complexity, poor reproducibility, loss of characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

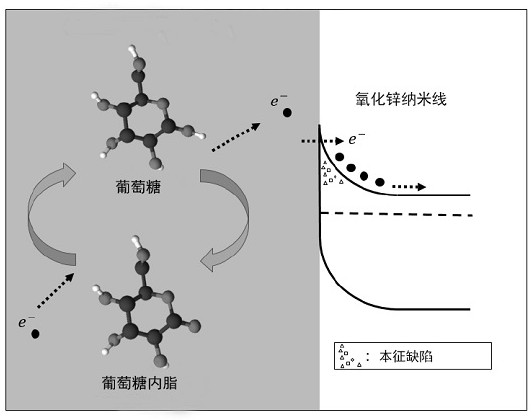

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Cleaning treatment of substrate components

[0028] The substrate assembly used in the present invention includes a paper-based chip and a silicon substrate. In order to prevent the substrate assembly from being affected by impurities on the surface of the substrate assembly when laying the seed layer, it needs to be cleaned first. Paper-based chips are handled differently from silicon substrates and are handled separately. Open the paper-based chip from the wrapping paper, take out the new paper-based chip, rinse it with deionized water, dry it with a nitrogen spray gun, and then place it in a clean transparent box to avoid re-contamination of the surface. The silicon substrate is soaked in acetone first, and cleaned with an ultrasonic oscillator for 10 minutes to remove the remaining oil stains on the silicon substrate. Remove the remaining organic matter, then take out the silicon substrate, then soak it in deionized water and shake for 10 minutes to r...

Embodiment 2

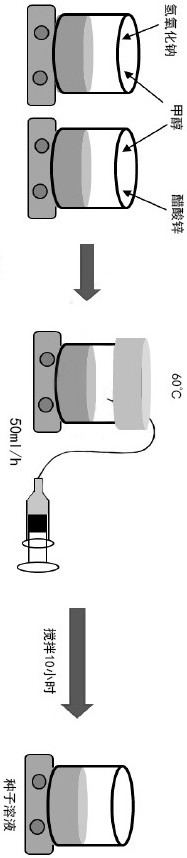

[0030] Embodiment 2: Preparation of seed solution and growth solution

[0031] image 3 Make a schematic diagram for the seed solution, which uses methanol as the solvent and sodium hydroxide and zinc acetate as the solute. Specifically, add 0.12 grams of sodium hydroxide to 100 ml of methanol to make a sodium hydroxide solution; add another 0.328 grams of zinc acetate to 150 ml of methanol to make a zinc acetate solution, and then stir the zinc acetate solution under electromagnetic heating After stirring in the container and heating to 60°C, the sodium hydroxide solution is then dripped into the zinc acetate solution at a rate of 50ml per hour by using a constant pressure delivery pump. After dripping 100ml, continue to heat at 60°C for three hours. After stirring for 10 hours, the solution turned from clear to turbid, and this solution was the seed solution of zinc oxide nanowires.

[0032] The growth solution is the solution needed in the hydrothermal method, and it is a...

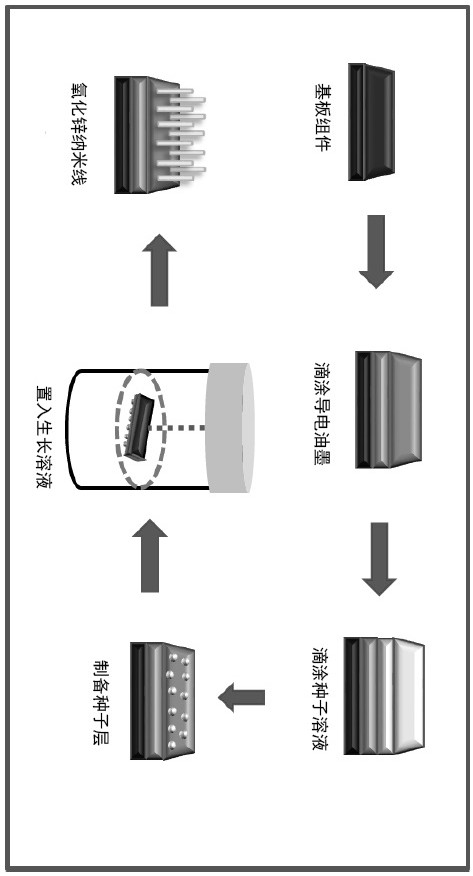

Embodiment 3

[0040] Example 3: Add conductive ink

[0041] After the substrate assembly is cleaned, zinc oxide nanowire materials will be grown on the working electrode of the paper-based chip. There are three electrodes (working electrode, opposite electrode, and reference electrode) on the paper-based chip of the present invention, so heat-resistant glue is used. Cover a part of the paper-based chip, use a puncher to operate the substrate assembly, punch a hole with the paper-based chip, make the hole face the working electrode and stick it on the paper-based chip, and the area of the hole is the same as the area of the working electrode, only Let the working electrode be exposed, while the other two electrodes are covered, and then add conductive ink, drop into the seed solution, and soak in the growth solution.

[0042] The conductive ink is used to increase the conductivity between the nanowire and the working electrode and increase the current value for sensing the glucose concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com