Torque sensor

A technology of torque sensor and Hall sensor, which is applied in the direction of force/torque/power measuring instrument, instrument, torque measurement, etc., can solve the problem that the torque sensor is difficult to cope with the miniaturized current demand, so as to improve the measurement performance and simplify the assembly process, the effect of improving sensing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

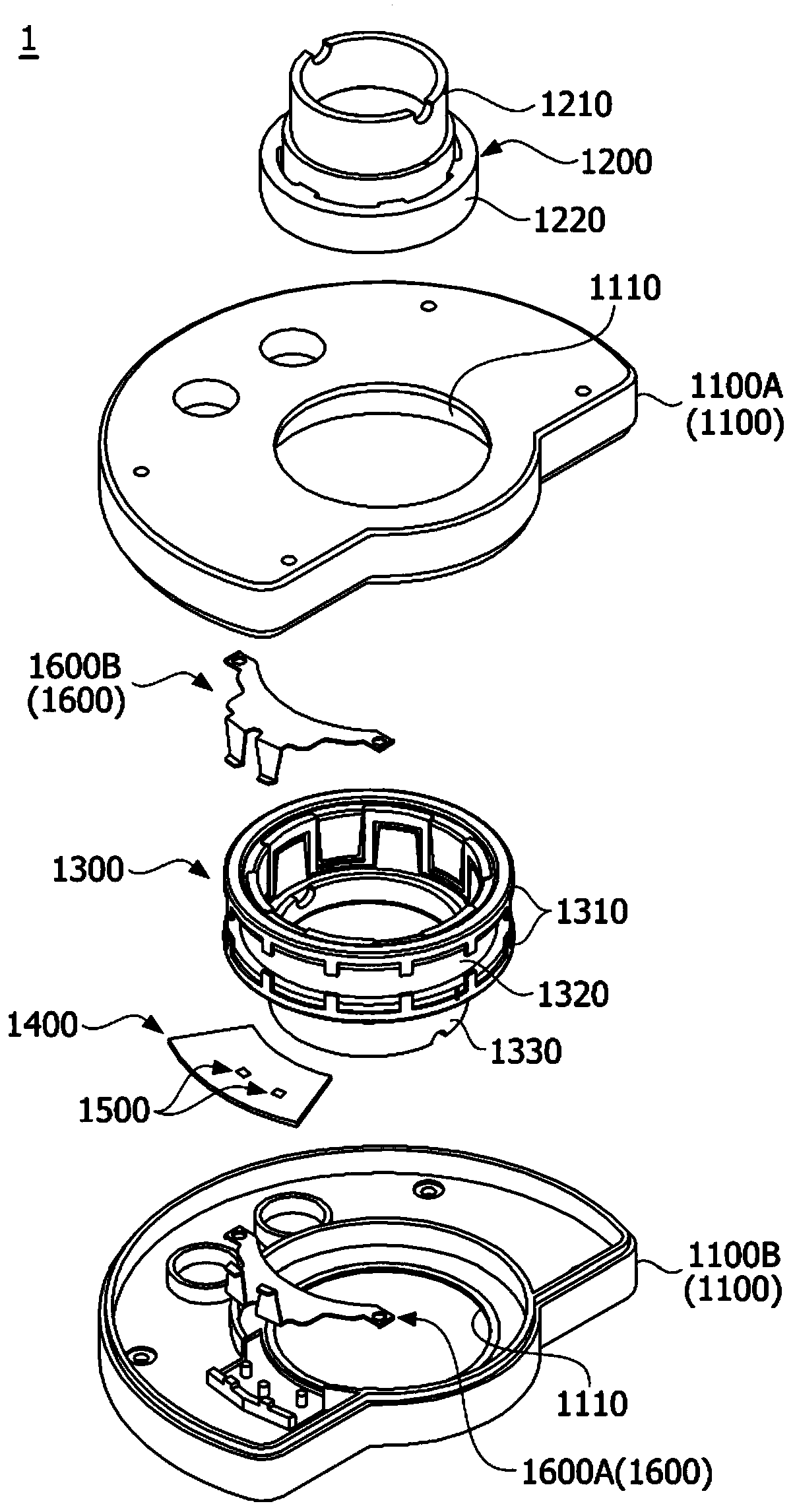

[0069] figure 1 is a view showing the torque sensor according to the first embodiment.

[0070] refer to figure 1 , the torque sensor 1 according to the first embodiment may include a housing 1100 , a rotor 1200 , a stator 1300 , a circuit board 1400 , a Hall sensor 1500 (Hall Integrated Circuit (IC)), and a collector 1600 .

[0071] The case 1100 may include upper and lower parts coupled to each other. In addition, the housing 1100 includes a hole 1110 provided at the center thereof. The stator 1300 is located within the bore 1110 . The circuit board 1400 and the collector 1600 may be disposed within the case 1100 .

[0072] The rotor 1200 is provided inside the stator 1300 . The rotor 1200 is connected to the input shaft of the steering shaft. Here, the input shaft may be a steering shaft connected to a steering wheel of the vehicle. The rotor 1200 may include a yoke 1210 having a cylindrical shape and a magnet 1220 disposed around the yoke 1210 . The input shaft is ...

no. 2 example

[0102] The torque sensor 2 according to the second embodiment may be provided between an input shaft (not shown) and an output shaft (not shown) of the steering shaft. Here, the torque sensor 2 may be referred to as a sensor assembly.

[0103] Figure 8 is an exploded perspective view showing the torque sensor according to the second embodiment, and Figure 9 is a side view of the rotor, stator, pinion, collector and circuit board of the torque sensor according to the second embodiment. here, Figure 8 and Figure 9 The shown x direction represents the axial direction, and the y direction represents the radial direction. In addition, the axial direction is perpendicular to the radial direction.

[0104] refer to Figure 8 and Figure 9 , The torque sensor 2 according to the second embodiment may include a housing 2100 , a rotor 2200 connected to an input shaft, a stator 2300 or 2300 a connected to an output shaft, a pinion 2400 , a collector 2500 , and a circuit board 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com