Manufacturing method for avoiding problem of faulty soldering of tab and cover plate

A manufacturing method and technology of tabs, which are applied to electrical components, circuits, battery pack components, etc., can solve problems such as low work efficiency, false welding and ignition of the tabs, and achieve the effect of avoiding false welding and good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The manufacturing method for avoiding the problem of false welding between the tab and the cover plate of the present invention will be further described in detail below in conjunction with the accompanying drawings.

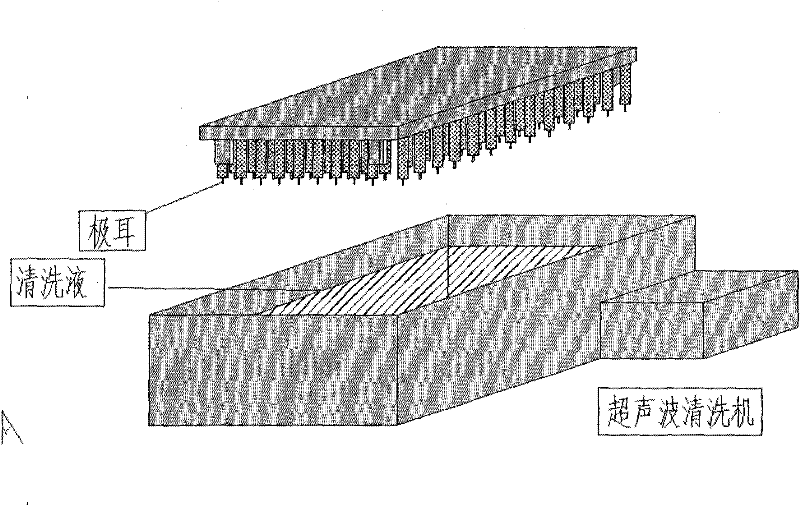

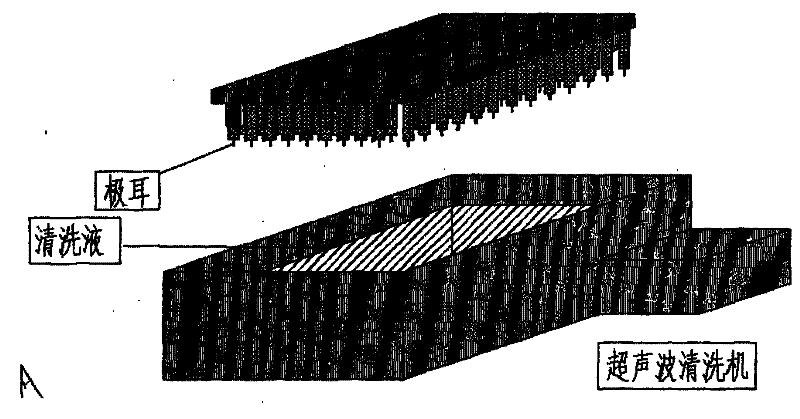

[0010] Such as figure 1 As shown, the present invention utilizes ultrasonic cleaning technology to remove impurities on the surface of aluminum lugs and remaining electrolyte, so as to prevent false welding caused by sparking during laser welding. The process is as follows: Straighten the aluminum tab of the battery filled with electrolyte, then put it into a special fixed tray, turn the tray upside down 180° and place it on the lifting frame, at this time, the battery shell mouth is facing down, open the down button, and then lower the tray Soak the tabs in the ultrasonic cleaning solution of pure water, set the frequency to 10KHZ, and work for 2 minutes to clean the electrolyte and other impurities on the tabs, and then dry the tabs; when the battery ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com