High-voltage side driving circuit

A driving circuit, high-voltage side technology, applied in electrical components, adjusting electrical variables, instruments, etc., can solve problems such as low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the description of the present invention more detailed and complete, please refer to the drawings and various embodiments, and the same numbers in the drawings represent the same components. On the other hand, well-known circuit components have not been described in the embodiments in order not to limit the invention unnecessarily.

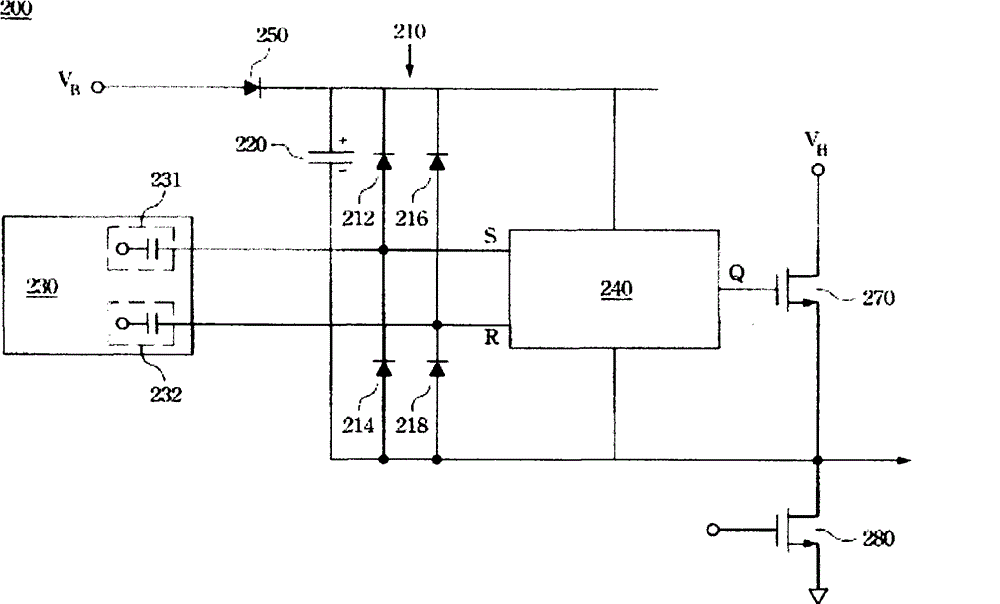

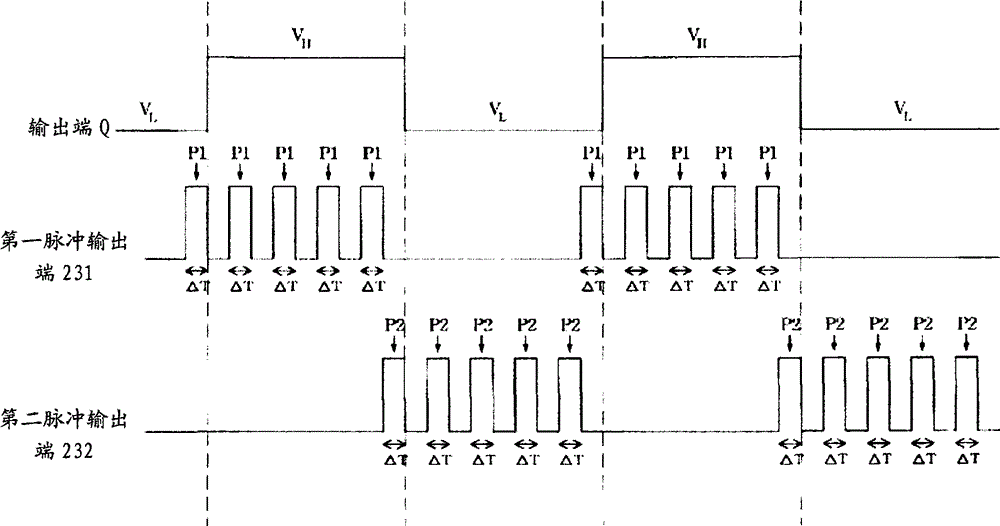

[0033] Please refer to figure 2 , which discloses an equivalent circuit diagram of a high side driver circuit (high side driver) according to an embodiment of the present invention. figure 2 Among them, the high side driving circuit 200 may include a bridge rectifier 210 , a bootstrap capacitor 220 , a signal generator 230 and a latch circuit 240 . The bridge rectifier 210 may include a first diode 212 , a second diode 214 , a third diode 216 and a fourth diode 218 . Wherein, the first diode 212 has a first anode and a first cathode. The second diode 214 has a second anode and a second cathode, wherein the second catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com