Method and device for eliminating pool effect

A technology of pool effect and puddle, which is applied in the direction of removing conductive materials by mechanical methods and chemical/electrolytic methods, can solve the problems of blocking potion etching effect, circuit short circuit, slow potion exchange reaction, etc., to achieve Eliminate the pool effect, speed up the potion exchange, and improve the effect of the process ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation method of the present invention will be further described below in conjunction with the embodiments.

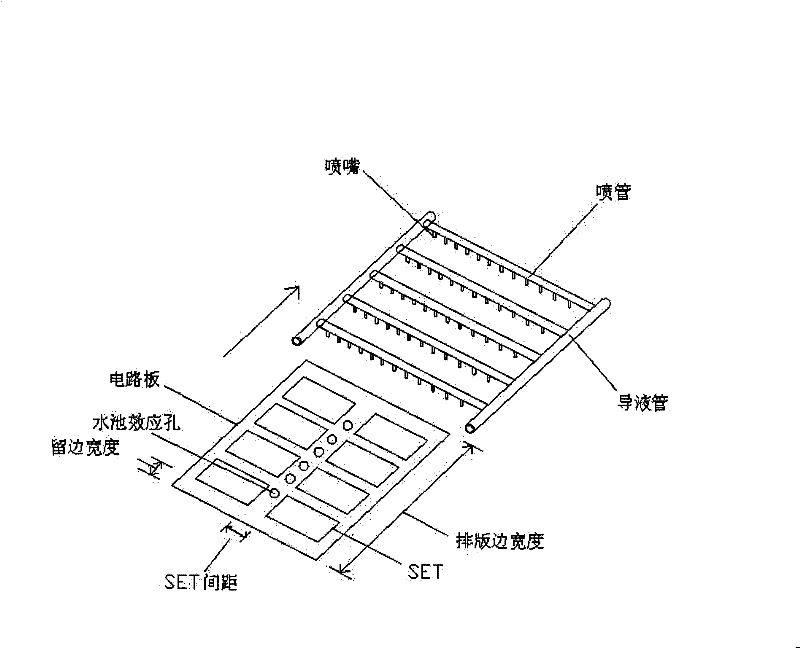

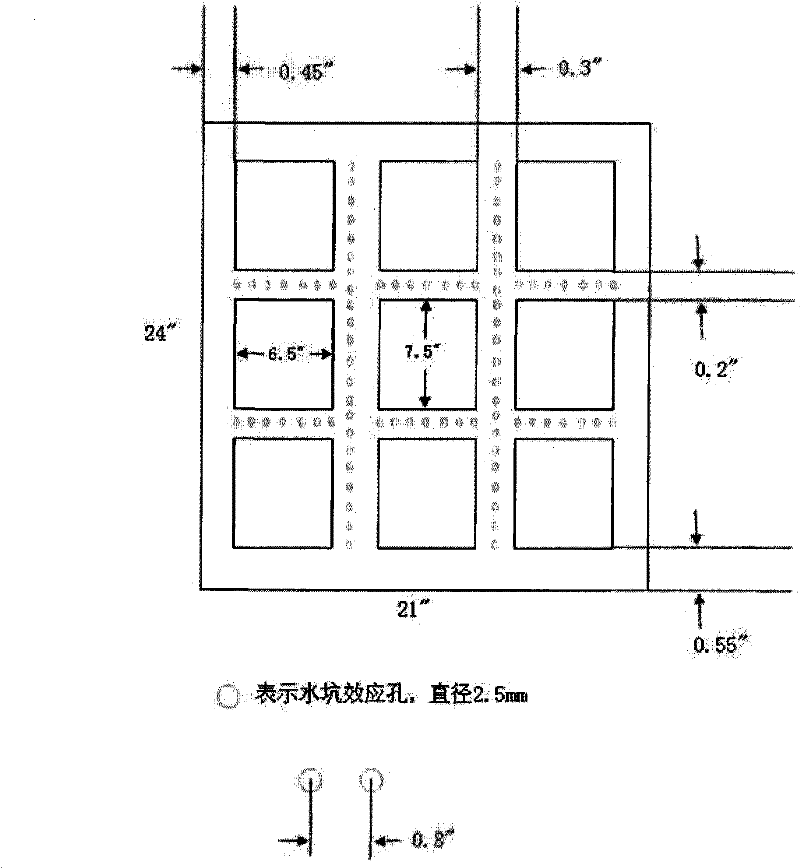

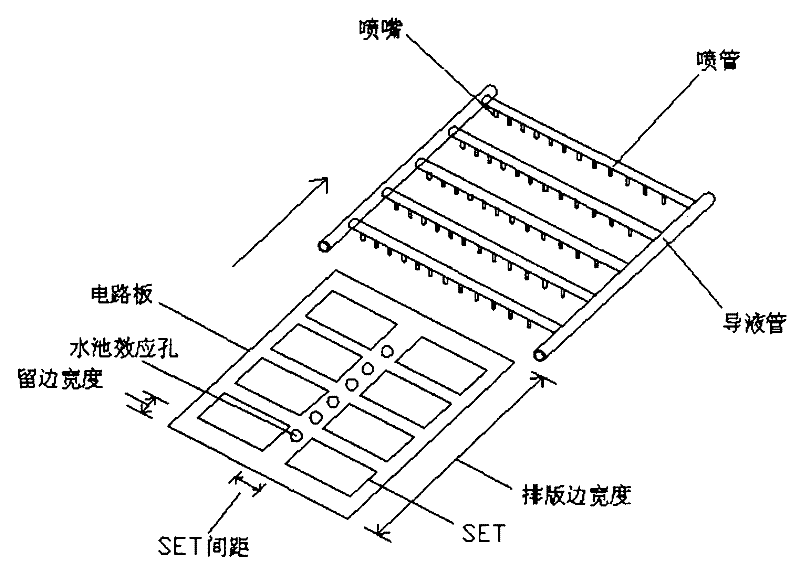

[0022] In the process of circuit board production, in order to obtain the required circuit, a series of operations are required, and an important step is etching. At present, the etching line in the industry is mainly horizontal etching. The principle is to spray liquid medicine up and down to achieve line etching. The liquid medicine sprayed from above will form a pool effect on the surface of the circuit board due to poor fluidity. The exchange reaction of the liquid medicine is slow and remains on the board surface. Due to the poor fluidity of the potion, the fresh potion cannot be replenished immediately, which will block the etching effect of the subsequent potion, resulting in insufficient etching uniformity, abnormal circuit short circuit and other quality problems.

[0023] The main purpose of the method for eliminating the pool effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com