Preparation method of polyimide film

A polyimide film and aromatic diamine technology, which is applied in the field of polyimide film preparation, can solve the problems of high polyimide preparation cost, insufficient film strength, and reduced linear expansion coefficient and mechanical strength. , to eliminate the charge-transfer complex) effect, increase solubility and transparency, and provide dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

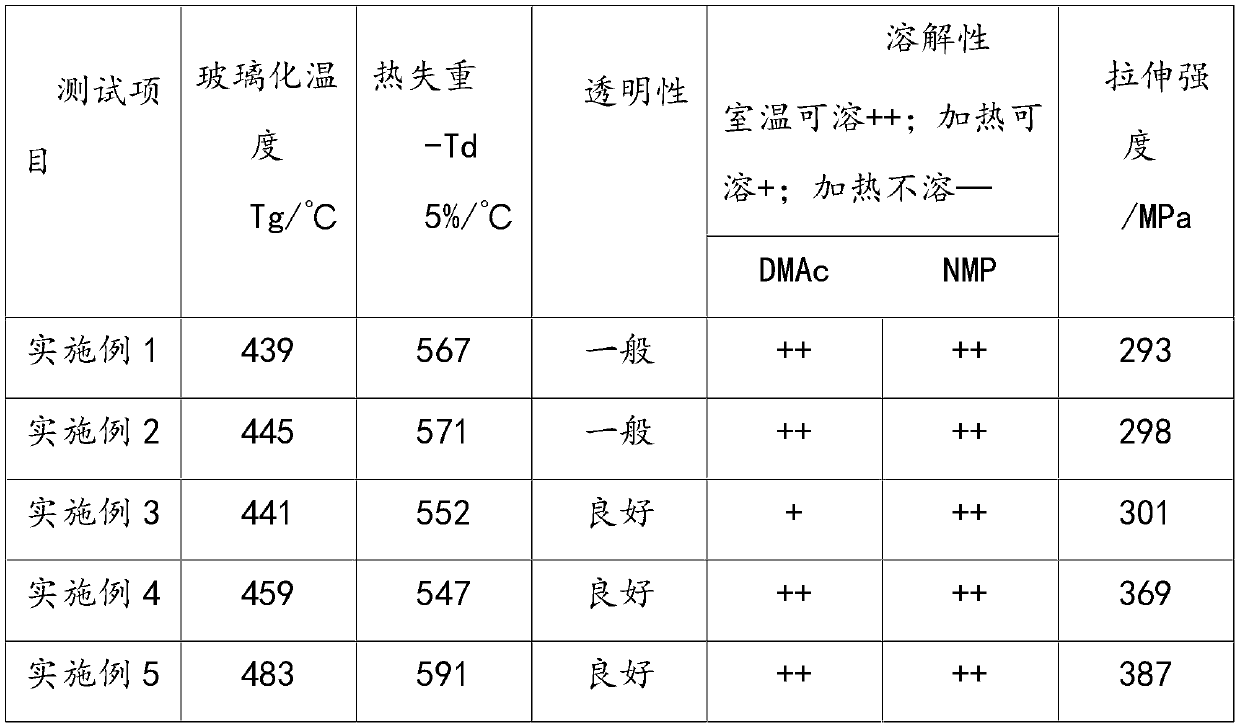

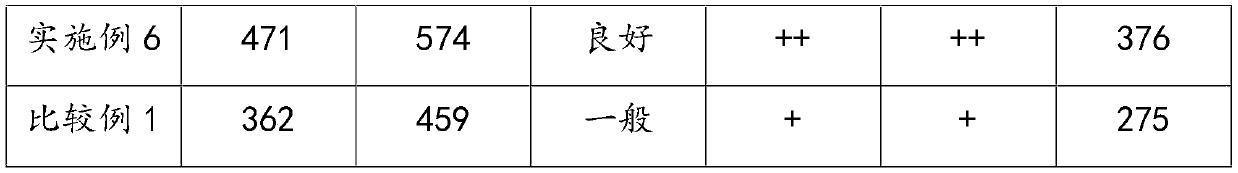

Examples

Embodiment 1

[0025] S1. Divide pyromellitic dianhydride into two equal parts, and simultaneously add them to the reactor containing fluorine-containing diamine N-methylpyrrolidone solution from different feeding ports to react for 3 hours, wherein pyromellitic dianhydride The molar ratio to fluorine-containing diamine is 1:1.05;

[0026] S2. Adding a dehydrating agent and fully stirring at 4°C to obtain a fluorine-containing polyamic acid solution;

[0027] S3. Coat the fluorine-containing polyamic acid solution on a glass plate, and heat in an argon oven at 50°C, 150°C, 250°C, 200°C, 250°C, 300°C, and 400°C for 1 hour each time to obtain Polyimide film.

Embodiment 2

[0029] S1. Divide pyromellitic dianhydride into two equal parts, and simultaneously add them to the reactor containing fluorine-containing diamine N-methylpyrrolidone solution from different feeding ports to react for 5 hours, wherein pyromellitic dianhydride The molar ratio to fluorine-containing diamine is 1:1.10;

[0030] S2. Adding a dehydrating agent and fully stirring at 7°C to obtain a fluorine-containing polyamic acid solution;

[0031] S3. Coat the fluorine-containing polyamic acid solution on a glass plate, and heat in an argon oven at 50°C, 150°C, 250°C, 200°C, 250°C, 300°C, and 400°C for 1 hour each time to obtain Polyimide film.

Embodiment 3

[0033] S1. Divide pyromellitic dianhydride into two equal parts, and simultaneously add them to the reactor containing fluorine-containing diamine N-methylpyrrolidone solution from different feeding ports to react for 7 hours, wherein pyromellitic dianhydride The molar ratio to fluorine-containing diamine is 1:1.15;

[0034] S2. Adding a dehydrating agent and fully stirring at 10°C to obtain a fluorine-containing polyamic acid solution;

[0035] S3. Coat the fluorine-containing polyamic acid solution on a glass plate, and heat in an argon oven at 50°C, 150°C, 250°C, 200°C, 250°C, 300°C, and 400°C for 1 hour each time to obtain Polyimide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com