Preparation method of polyimide

A technology of polyimide and prepolymer, which is applied in the field of polyimide preparation, can solve the problems of difficult balance between expansion coefficient and mechanical strength, difficult processing and forming, and insufficient film strength, so as to achieve easy long-term storage and improve mechanical strength. performance, the effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

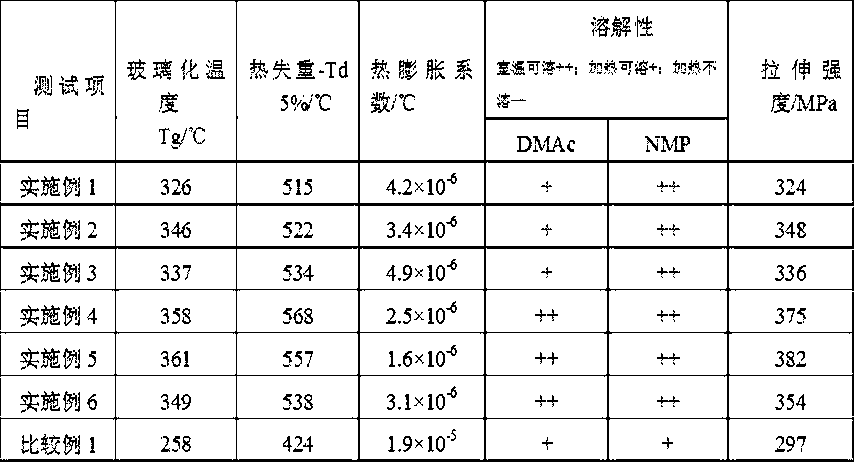

Examples

Embodiment 1

[0027] Step 1. Polymerize dianhydride and diamine in an ionic liquid according to a molar ratio of 1:1, wherein the ionic liquid is chlorinated 1,3-bis(2-methoxy-2-oxyethyl)imidazole and 1, 3-bis(2-methoxy-2-oxyethyl)imidazolium hexafluorophosphate is prepared at a molar ratio of 1:1, and the mass ratio of the total mass of diamine and dianhydride to the ionic liquid is 1~ 3. React at room temperature for 10 hours to obtain a polyimide prepolymer solution.

[0028] Step 2. Mix the polyimide prepolymer solution with a water-soluble acrylic resin and a saturated polyester resin solution in a molar ratio of 2:1, react at 80° C. for 1 h, cool, and add 20% of the total volume The organic solvent was refluxed for 2 hours, the organic solvent was evaporated, and the reflux was continued for 2 hours to obtain a polyimide premixed solution.

[0029] Step 3: Mix the polyimide premixed solution with deionized water to obtain a precipitate, filter and dry the precipitate to obtain a poly...

Embodiment 2

[0033] Step 1. Polymerize dianhydride and diamine in an ionic liquid according to a molar ratio of 1:1, wherein the ionic liquid is chlorinated 1,3-bis(2-methoxy-2-oxyethyl)imidazole and 1,3-bis(2-methoxy-2-oxyethyl)imidazolium hexafluorophosphate is prepared according to the molar ratio of 1:1, and the mass ratio of the total mass of diamine and dianhydride to the ionic liquid is 1: 5. React at room temperature for 15 hours to obtain a polyimide prepolymer solution.

[0034] Step 2. Mix the polyimide prepolymer solution with a water-soluble acrylic resin and a saturated polyester resin solution in a molar ratio of 2:1, react at 100°C for 1 hour, cool, and add 30% of the total volume After the organic solvent was refluxed for 5 hours, the organic solvent was evaporated, and the reflux was continued for 5 hours to obtain a polyimide premixed solution.

[0035] Step 3: Mix the polyimide premixed solution with deionized water to obtain a precipitate, filter and dry the precipita...

Embodiment 3

[0039]Step 1. Polymerize dianhydride and diamine in an ionic liquid according to a molar ratio of 1:1, wherein the ionic liquid is chlorinated 1,3-bis(2-methoxy-2-oxyethyl)imidazole and 1, 3-bis(2-methoxy-2-oxyethyl)imidazolium hexafluorophosphate is prepared at a molar ratio of 1:1, and the mass ratio of the total mass of diamine and dianhydride to the ionic liquid is 1~ 10. React at room temperature for 20 hours to obtain a polyimide prepolymer solution.

[0040] Step 2. Mix the polyimide prepolymer solution with a water-soluble acrylic resin and a saturated polyester resin solution in a molar ratio of 2:1, react at 120°C for 2 hours, cool, and add 35% of the total volume The organic solvent was refluxed for 10 hours, the organic solvent was evaporated, and the reflux was continued for 10 hours to obtain a polyimide premixed solution.

[0041] Step 3: Mix the polyimide premixed solution with deionized water to obtain a precipitate, filter and dry the precipitate to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com