Sliding cone structure

A technology of split structure and cone, applied in the field of sliding cone structure, can solve the problems of reduced machining accuracy of boring bars, increased machining cost, inability to guarantee accuracy, etc., and achieves shortened machining length, low machining cost and good use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

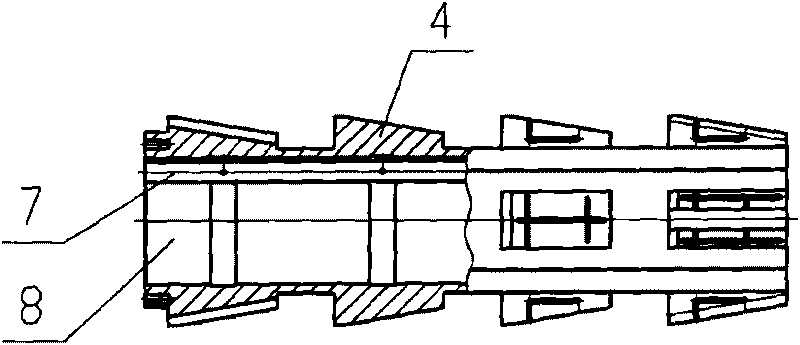

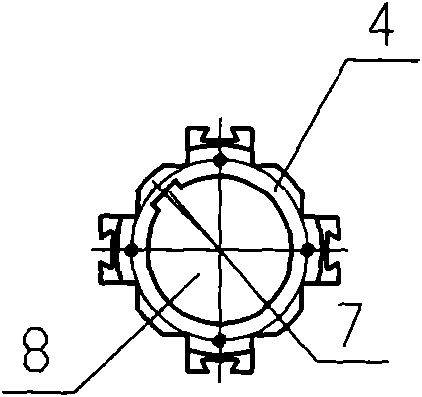

[0014] Such as Figure 4 ~ Figure 6 As shown, including middle hole 8, sliding keyway 7, front cone 9, middle cone 10, rear cone 11, spacer 12, connecting rod 13, process shaft 14, blind hole 15 and through hole 16, etc.

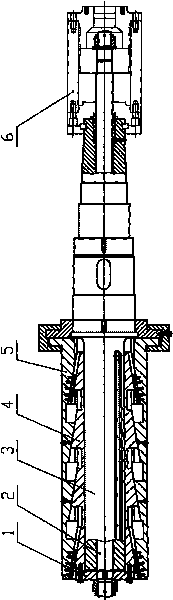

[0015] Such as Figure 4 As shown, it is a schematic view of the expansion and contraction mechanism installed with the reel of the uncoiler of the present invention. Compared with the expansion-contraction mechanism in the prior art, the expansion-contraction mechanism has no change in other parts, but the structure of the sliding cone has been improved.

[0016] The cone of the present invention is a split structure, which is connected into one body by connecting rods 13 . The cone is divided into a front cone 9 , a middle cone 10 and a rear cone 11 , and a spacer 12 is arranged between the front cone 9 and the middle cone 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com