Clamp type sheet automatic-feeding device of hydraulic machine

An automatic feeding, clamp-type technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of inability to accurately transfer the sheet material to the required position, increase the manufacturing cost of the press, and inability to adapt to the hydraulic press, etc. Achieve easy operation and maintenance, improve production efficiency, and save internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

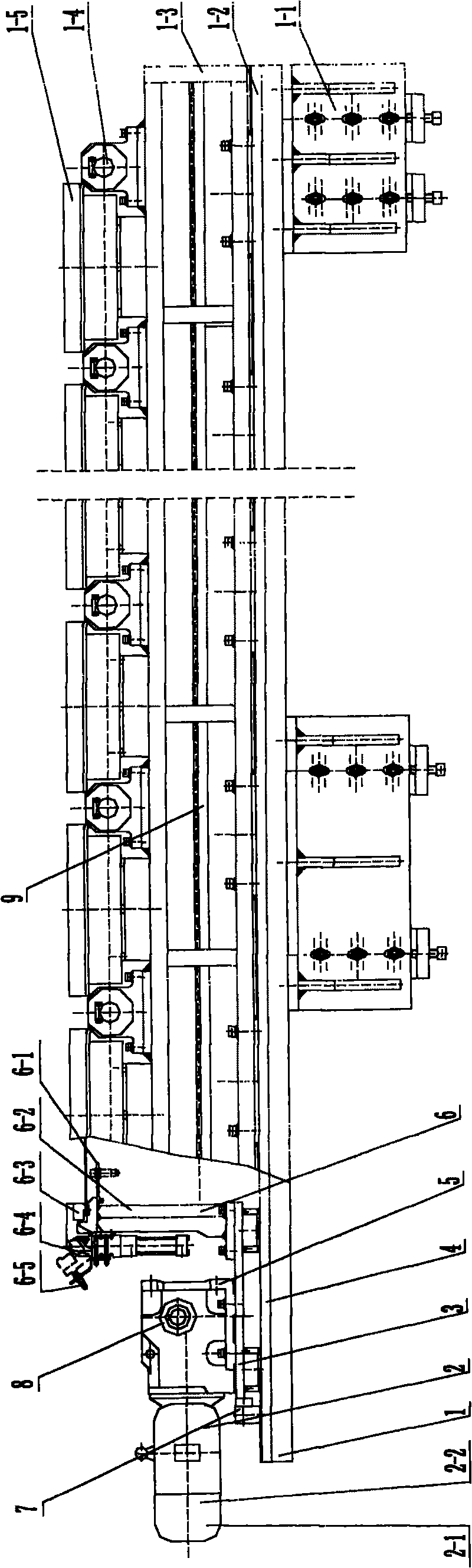

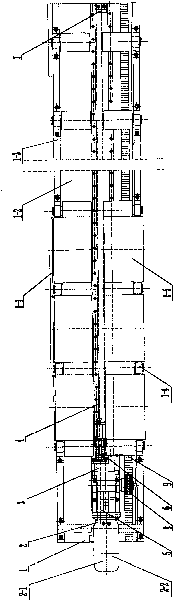

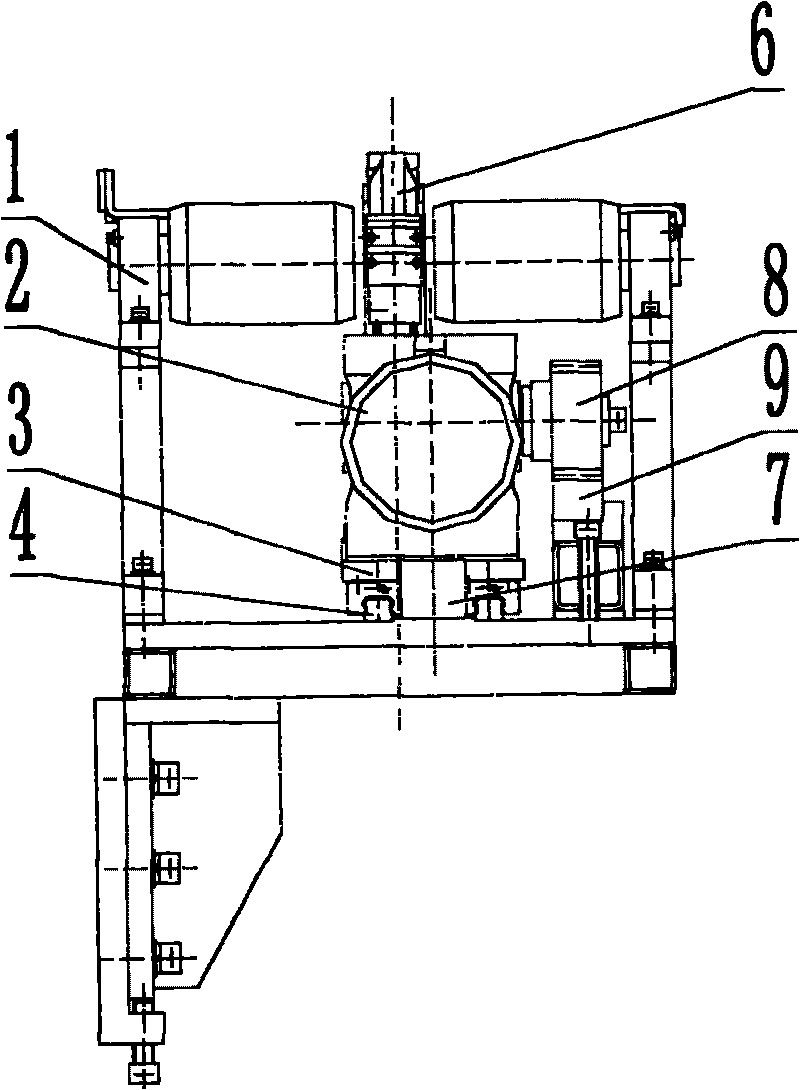

[0016] See Figure 1-Figure 4 , Hydraulic press clamp type automatic sheet material feeding device, including mechanism support frame 1, brake motor 2, reducer 5 and clamp mechanism 6. The mechanism support frame 1 is composed of a base 1-2, side brackets 1-3, rollers 1-4, and support plates 1-5. The side brackets are fixed on both sides of the base 1-2, and several brackets are installed between the two sides. The rollers are provided with a support plate between the rollers, and a support 1-1 for connecting with the inner side of the press column is also provided at the bottom of the base. A linear guide 4 is fixed inside the mechanism support frame 1, and a base 3 is provided on the linear guide to be in a dynamic fit. A brake motor 2 is installed on the base 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com