Paper disc box and making method thereof

A production method and disc technology, applied in the field of disc boxes, can solve the problems of unfavorable production efficiency, cumbersome production process, low efficiency, etc., and achieve the effects of simple and fast production process, improved production efficiency, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means adopted by the present invention and its decorative effect, the following is a detailed description in conjunction with preferred embodiments of the present invention and accompanying drawings.

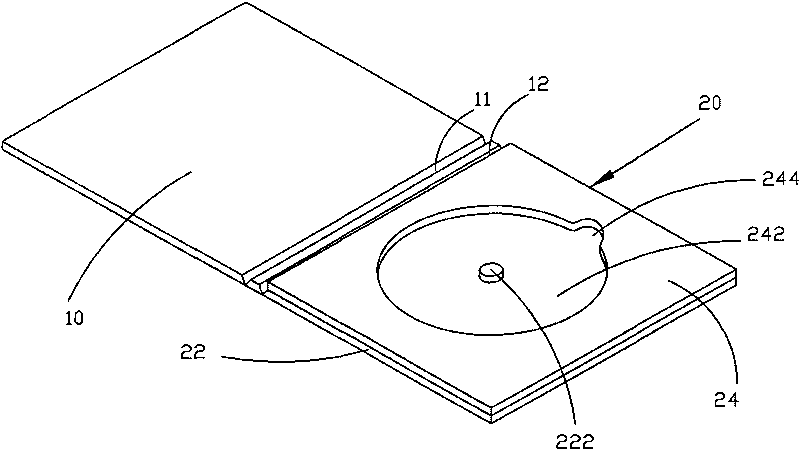

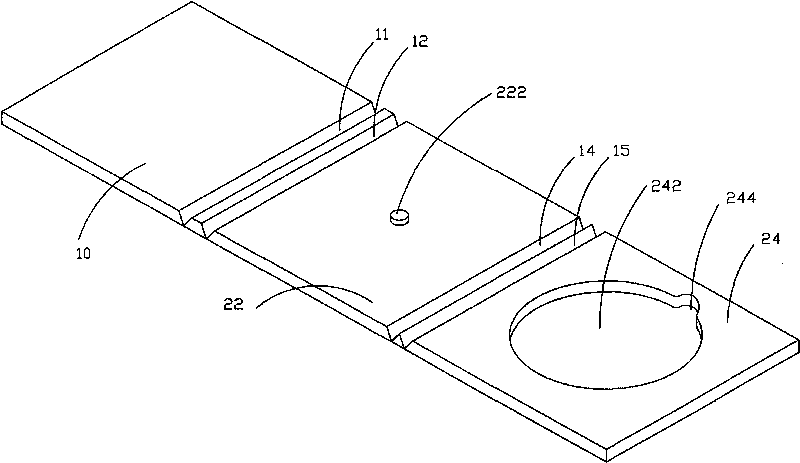

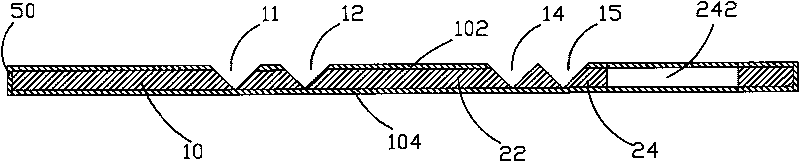

[0035] Such as Figure 1-3 As shown, the paper disc box provided by the present invention includes: a top cover 10, and a bottom cover 20 integrally connected with the top cover 10, the bottom cover 20 includes a bottom plate 22, and is integrally connected with the bottom plate 22 And overlap the inner layer plate 24 on the base plate 22, the base plate 22 is provided with a support 222, the inner layer plate 24 is provided with a through hole 242 for accommodating the optical disc, and an arc-shaped gap 244 communicated with the through hole 242 To facilitate the loading and unloading of the optical disc, the supporting member 222 is provided at the center position corresponding to the through hole 242 of the inner layer plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com