Hydraulic transmission lift truck

A technology for hydraulic transmission and lift trucks, applied in the field of lift trucks, can solve problems such as hidden safety hazards, low mechanical efficiency, enterprise losses, etc., and achieve the effect of reducing labor intensity of workers and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

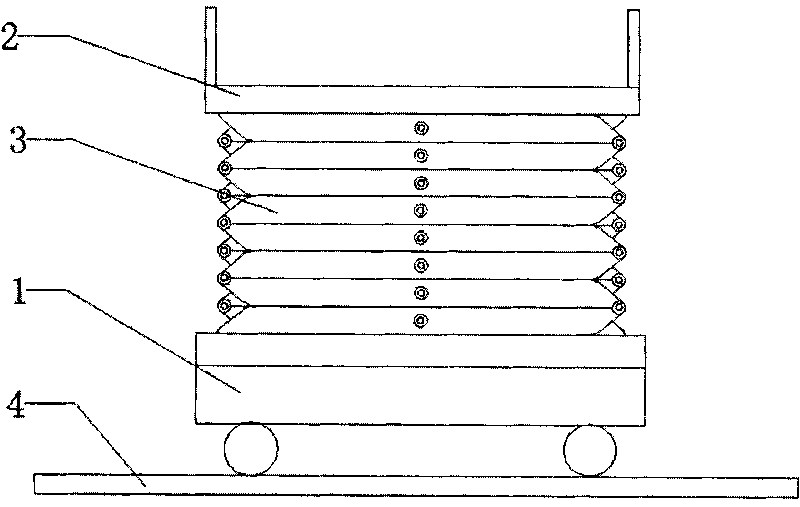

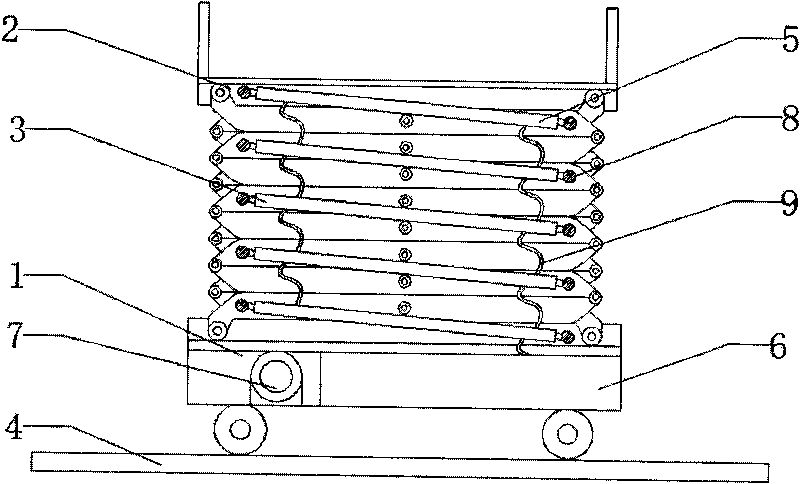

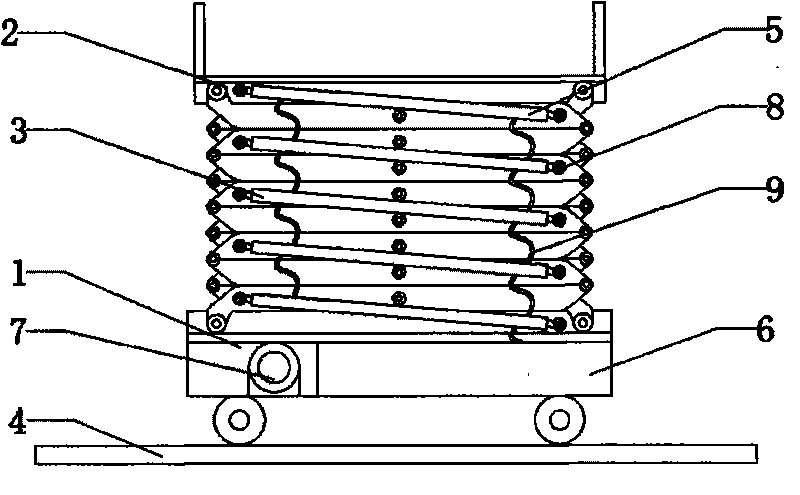

[0021] Such as Figure 1-2 As shown, the hydraulic transmission lift car of the present invention includes a bottom working platform 1, a top operating platform 2, a transmission frame 3, a moving guide rail 4, and a hydraulic system. The bottom working platform 1 is connected with the moving guide rail 4 through rollers, and the bottom working platform 1 is connected with a transmission frame 3 through rollers, and the top of the transmission frame 3 is connected to the top operating platform 2 through rollers. The transmission frame 3 is cross-connected by two "zigzag" frames, and the relative positions Connect with connecting rod 8;

[0022] Described hydraulic system comprises hydraulic column 5, hydraulic pool 6 and drive motor 7, is provided with hydraulic tube 9 and connects hydraulic column 5 and hydraulic pool 6, is connected with drive motor 7 between hydraulic tube 9 and hydraulic pool 6, and the hydraulic pressure The pool 6 and the driving motor 7 are located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com