Method for controlling pressure of blast furnace top by adopting gas dry dust removing device

A technology of furnace top pressure and dry dust removal, applied in blast furnaces, dust collectors, blast furnace details, etc., can solve problems such as furnace top pressure fluctuations and affect production, and achieve the effect of furnace top pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

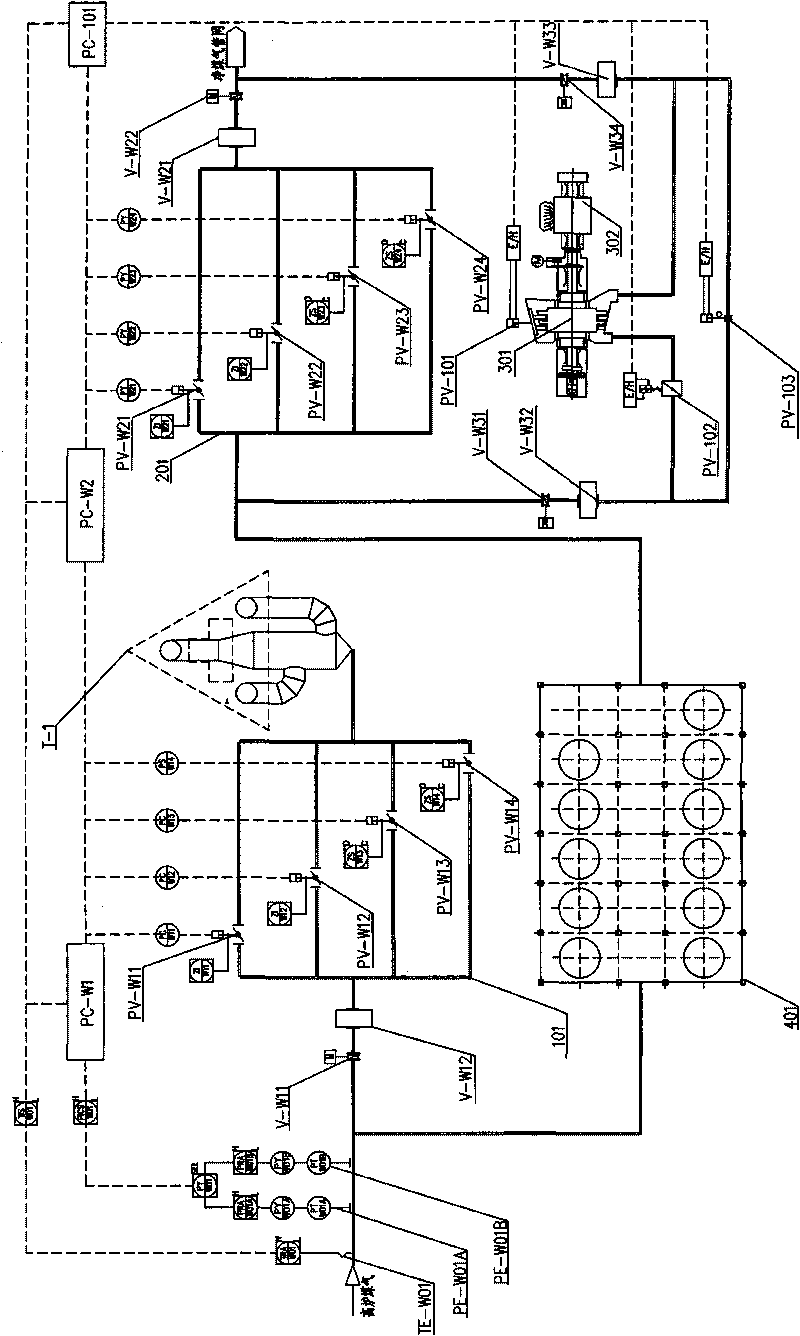

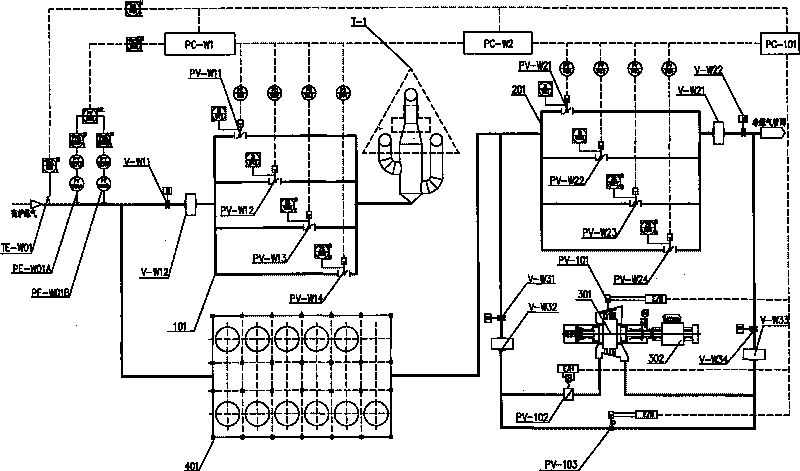

[0010] Such as figure 1 As shown, the blast furnace top pressure control system using the gas dry dedusting device includes the gas release tower T-1, the gas dry dedusting device 401, the clean gas pipeline network and the TRT system, which also includes the crude gas pressure reducing valve group 101 , net gas pressure reducing valve group 201, TRT stationary vane / quick opening regulating valve group, and the crude gas pressure reducing valve group control module PC-W1, which controls these three valve groups respectively, and the net gas pressure reducing valve group control module PC- W2, TRT vane / quick opening control valve control module PC-101.

[0011] The blast furnace gas is produced from the blast furnace and is divided into two paths after passing through the gravity dust collector. One path passes through the crude gas pressure reducing valve group 101 and enters the gas release tower T-1; the other path passes through the gas dry dust removal device 401, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com