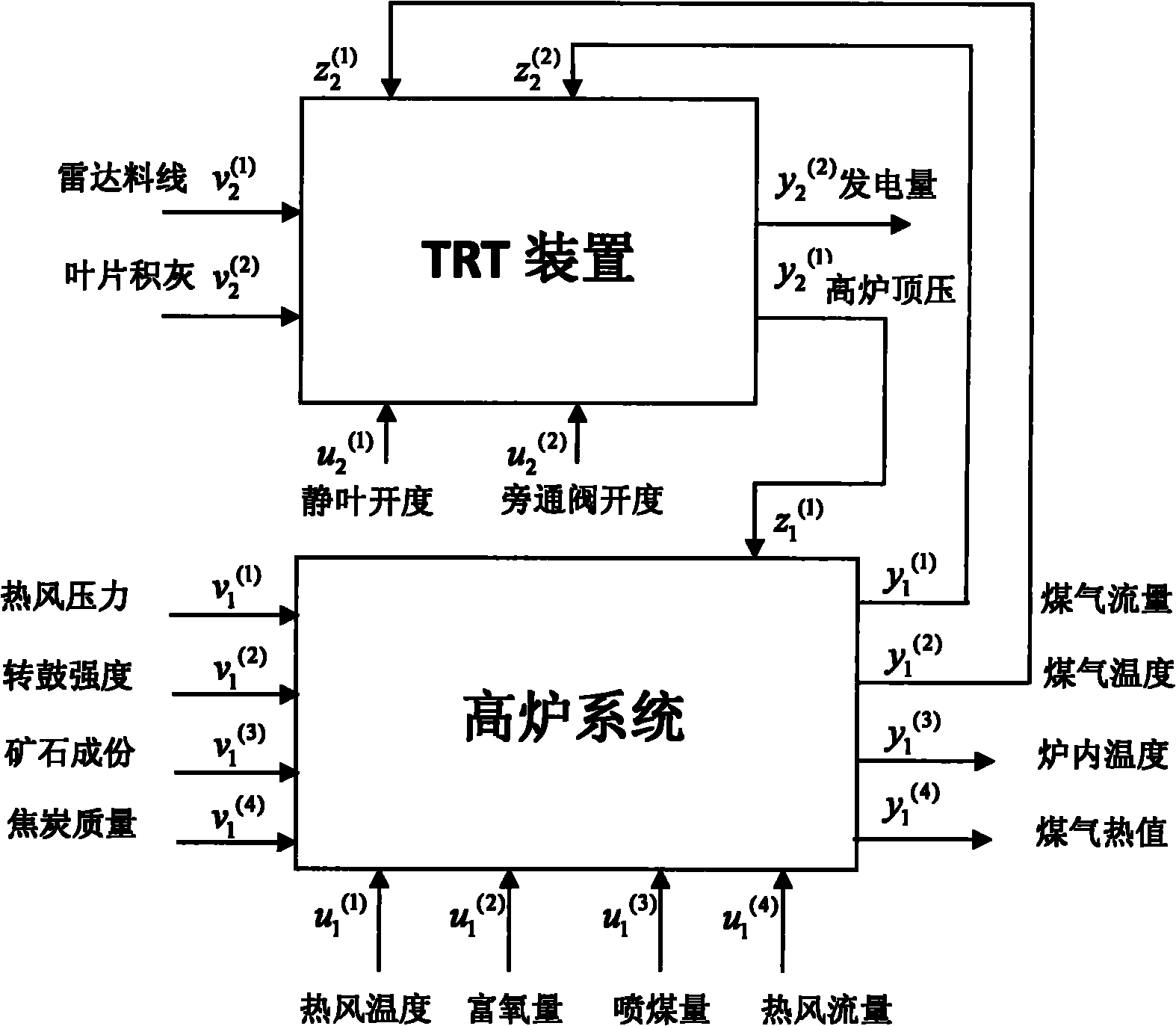

Distributed coordination control method of blast furnace system and pressure recovery turbine (TRT) device

A technology of distributed coordination and control method, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of not considering coordination and optimization control, resource waste efficiency, excessive control effect, etc., to achieve the best overall performance, good optimization performance, little control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The utility model will be further described below in conjunction with the accompanying drawings and specific examples.

[0032] Concrete steps of the present invention are as follows:

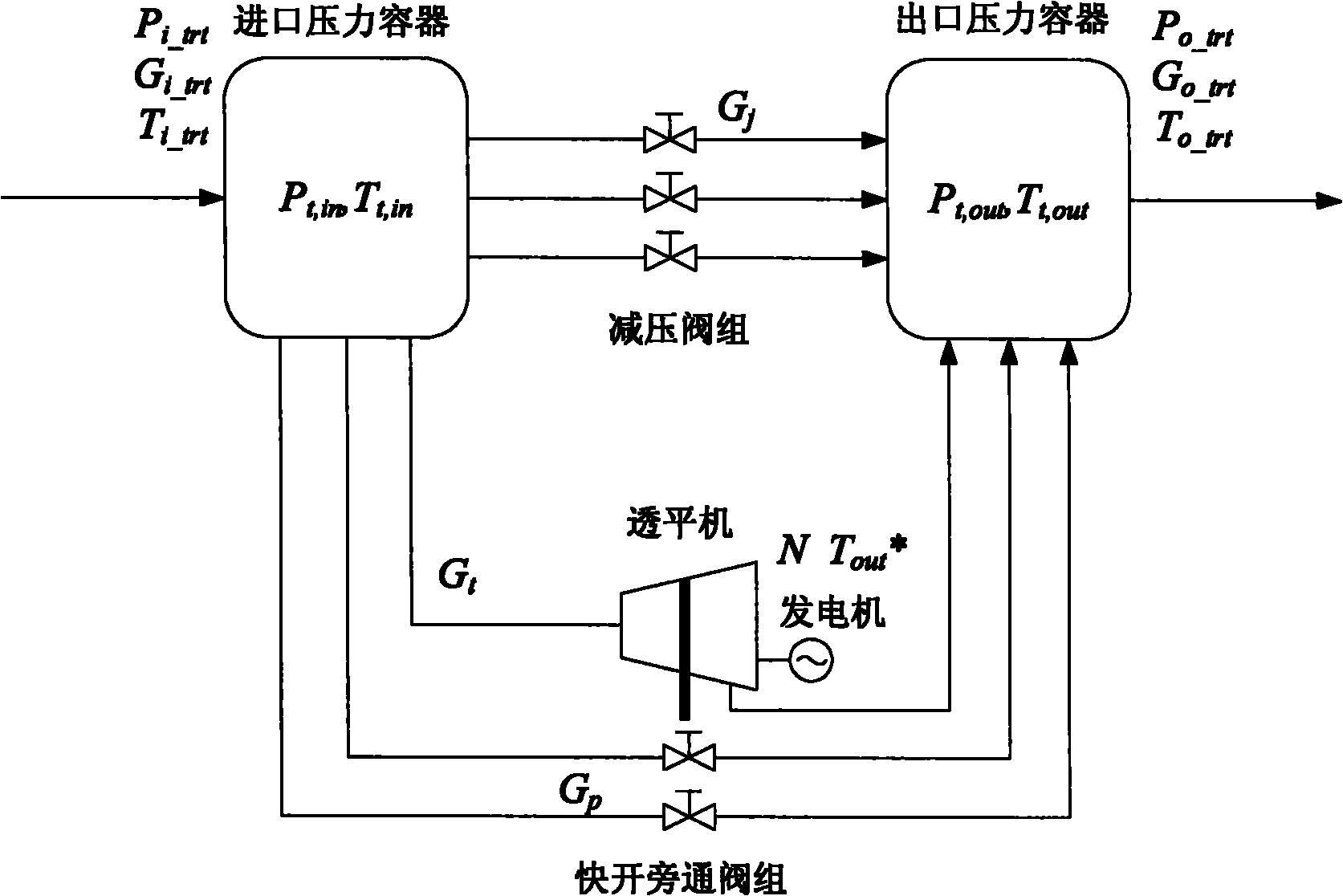

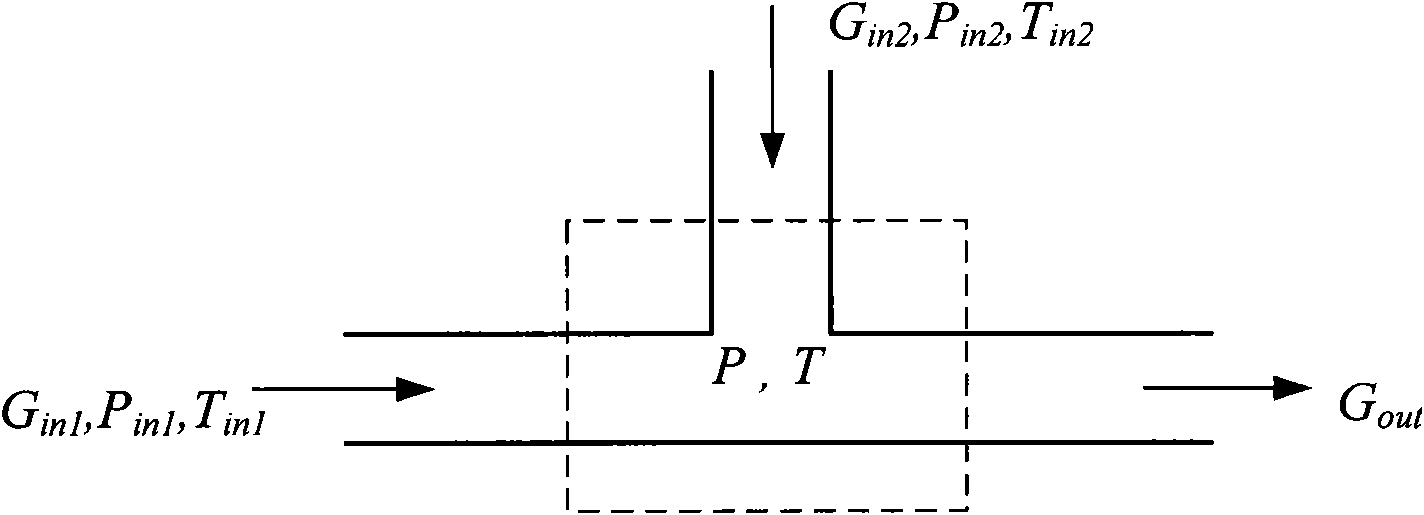

[0033] 1. Description and dynamic modeling of blast furnace system:

[0034] Blast furnace production is a physical, chemical, and kinetic process under high temperature, high pressure, and airtight conditions. Since there are many factors that affect the safe and stable production of blast furnaces and the improvement of molten iron production and quality, the gas temperature and pressure in the furnace are mutually affected and are closely related to the furnace conditions. As temperature information, one of the important indicators to measure blast furnace conditions and molten iron quality, iron and steel plants mainly obtain it from physical temperature (hot metal temperature) and chemical temperature (hot metal silicon content). Although a large number of thermocouples are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com