Tube-shaped foundation structure with force bearing ring

A technology of cylindrical foundation and load-bearing ring, which is applied in the direction of foundation structure engineering, construction, caisson, etc., and can solve the problems of insufficient vertical bearing capacity and pull-out force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

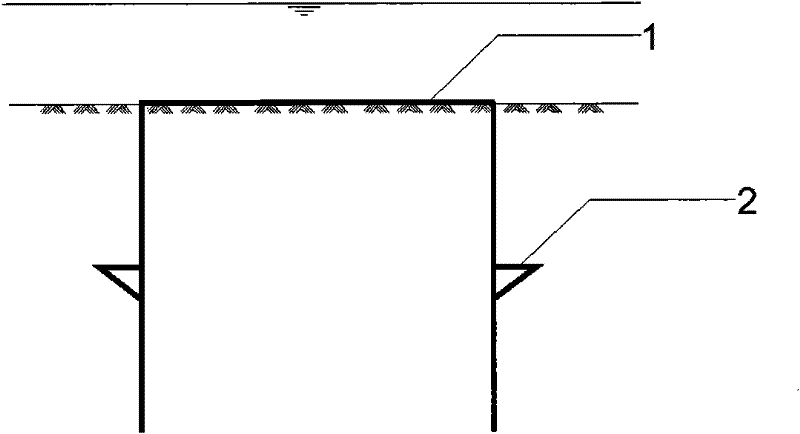

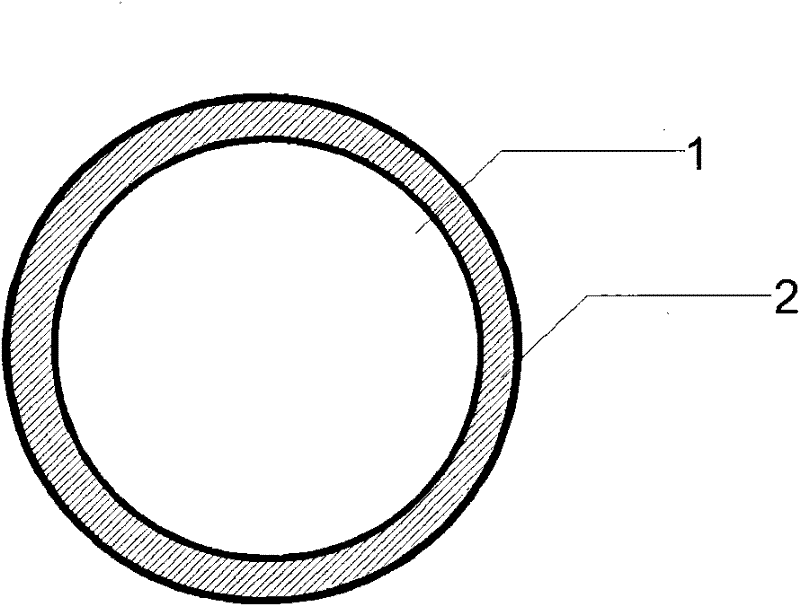

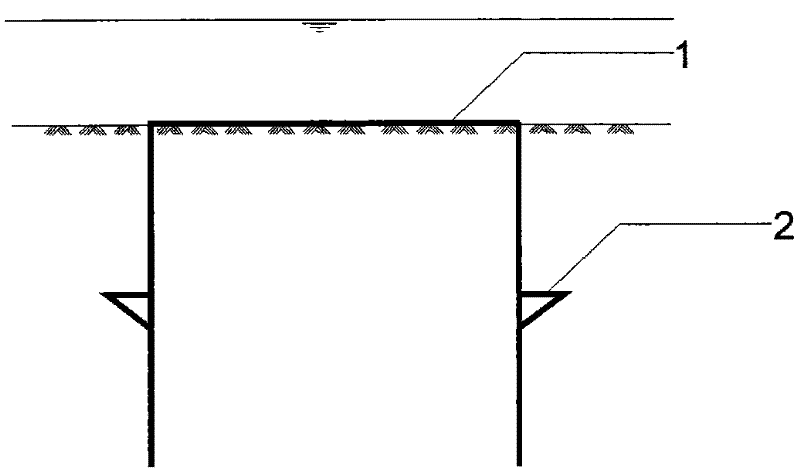

[0013] A cylindrical foundation structure with a bearing ring is composed of a cylindrical foundation 1 and a bearing ring 2 fixed on the outside of the cylinder wall of the cylindrical foundation 1 . In this embodiment, the cylindrical foundation has a diameter of 12m and a height of 10m; the load-bearing ring is made of steel plate with a triangular cross-section, 300mm high and 300mm wide.

[0014] The cylindrical foundation structure with load-bearing ring can improve the force mode of the cylindrical foundation when it is used. Because it can provide a larger cross-sectional area, it can provide end resistance when the cylindrical foundation is subjected to a downward force. When the cylindrical foundation is subjected to an upward force, it provides an upward pullout force, so that the cylindrical foundation provides a greater bearing capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com