Armor type steel plate concrete shear wall and construction scheme thereof

A steel plate concrete and reinforced concrete technology, applied to walls, building components, buildings, etc., can solve the problems of reducing the long-term performance and durability of structures, insufficient strength, and increasing the stability of columns, so as to improve long-term performance and durability, reduce Welding residual stress and the effect of maintaining continuous energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described below through specific examples, but the present invention is not limited thereto.

[0060] Below in conjunction with accompanying drawing, the present invention is described in further detail:

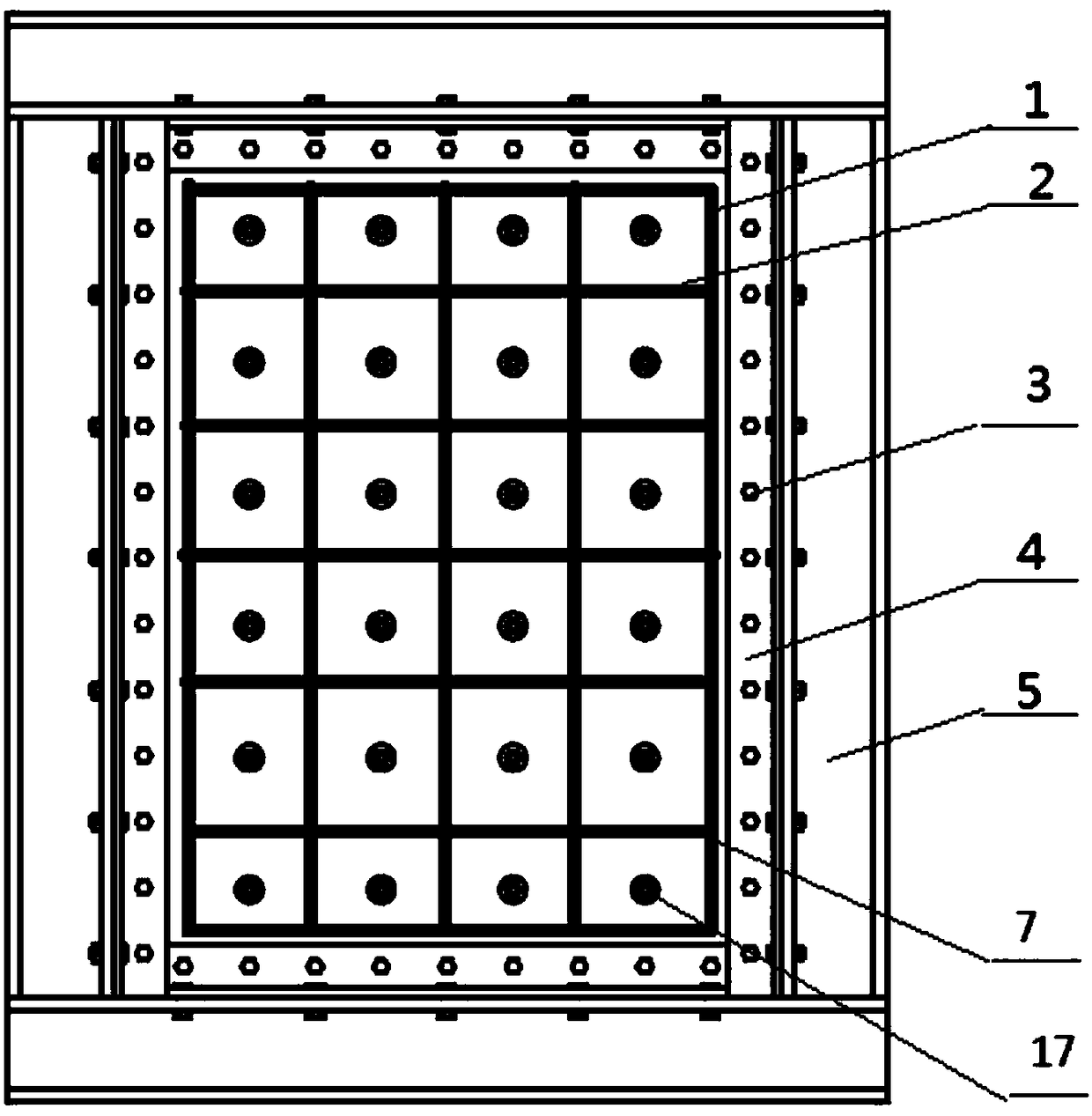

[0061] The combined steel plate shear wall structure of the present invention includes: edge components, angle steel, elastic rubber rings, concrete steel plate components and screw components. The specific construction plan is carried out in the following steps:

[0062] (1) The construction of the framework. The two ends of the first vertical edge member are respectively connected with the left end of the first horizontal edge member and the left end of the second horizontal edge member, wherein the left end of the first horizontal edge member and the left end of the second horizontal edge member are connected with the first vertical edge member The two ends of the second vertical edge member are respectively connected with the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com