A design method for pile-sheet wall structure of friction-stressed embankment

A design method and pile-slab structure technology, applied to underwater structures, foundation structure engineering, roads, etc., can solve the problems of high project investment, limited seismic performance, and difficult deformation of soil foundation reinforcement piles, etc., to achieve good safety, Improve the effect of force mode, good resistance to deformation and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

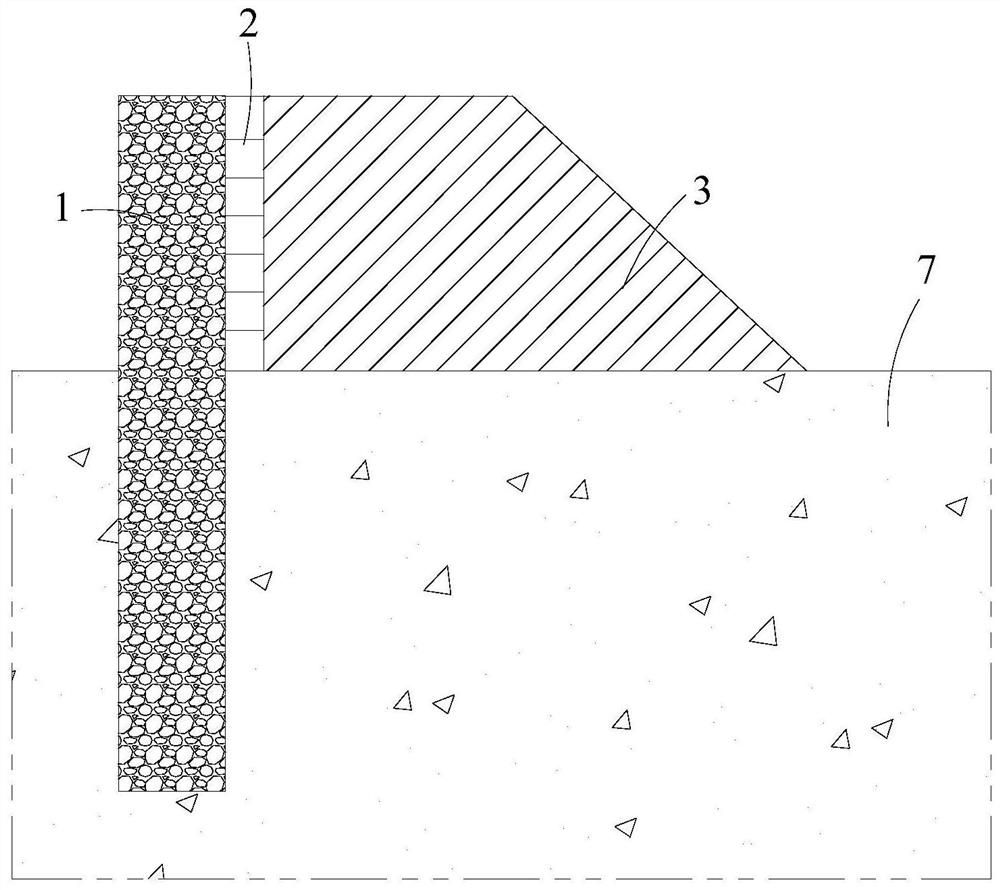

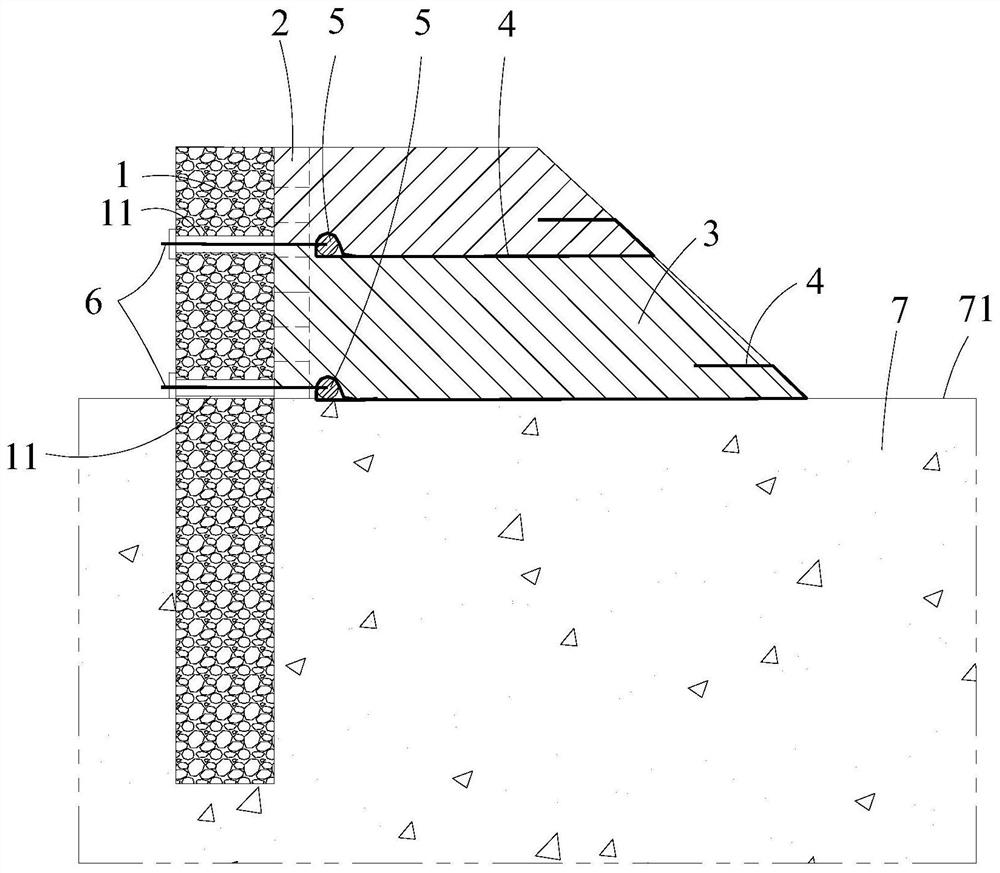

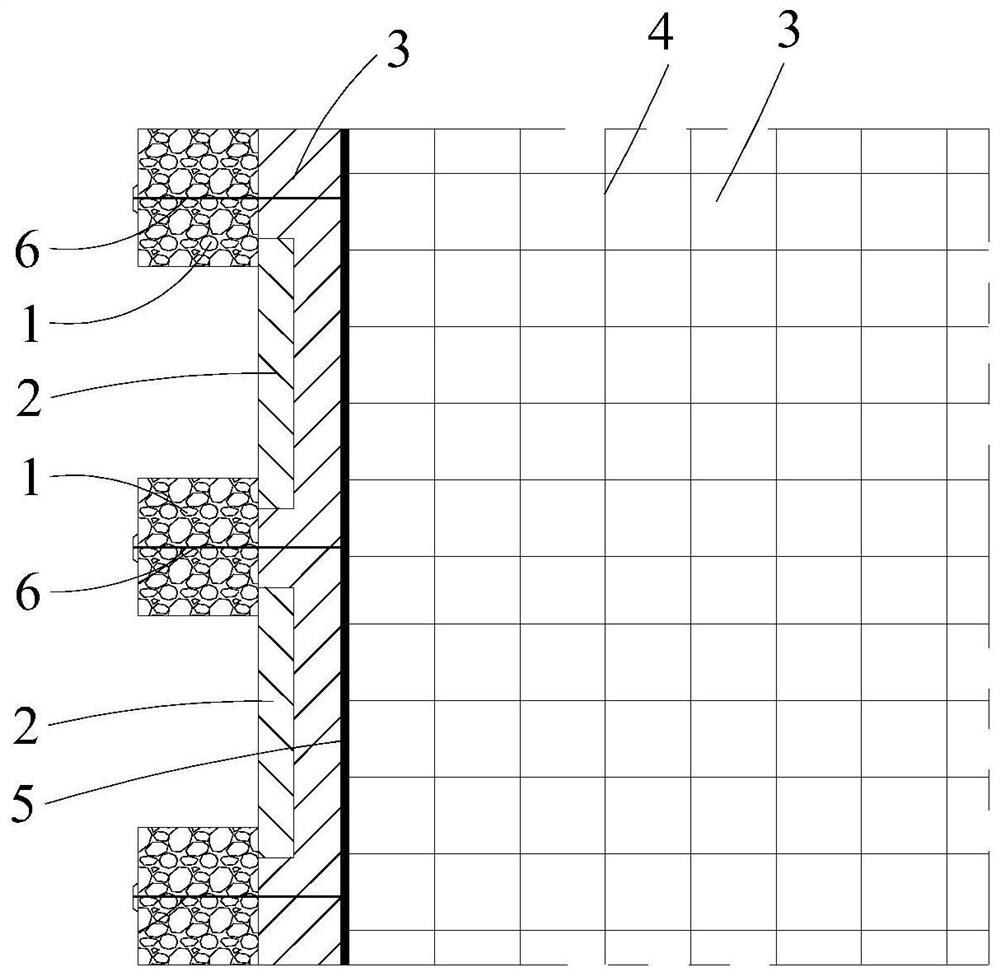

[0054] Such as Figure 2-3 As shown, a calculation method for the pile-slab wall structure of a frictional force type embankment is based on the pile-slab wall structure, which is specifically: a plurality of reinforcement components are set in the embankment filling body 3, and the multiple reinforcement components combine the described The embankment filling body 3 is divided into several layers from top to bottom, and the reinforcement pile 1 is provided with several connection parts 11 corresponding to the reinforcement parts from top to bottom, and the reinforcement parts and the corresponding connection parts 11 pass through Tension anchor cable 6 is connected;

[0055] Include the following steps,

[0056] ① Determine the surface friction coefficient f between the bidirectional geogrid 4 of the i-th layer and the embankment filling body 3 ci ;

[0057] ②Calculate the load W of the embankment filling body 3 overlying the bidirectional geogrid 4 of each layer from top ...

Embodiment 2

[0072] Such as Figure 2-3 As shown, this embodiment is described with an actual engineering example:

[0073] A pile-slab wall construction site of an embankment, the embankment filling height is 6m, the same kind of filler is used, and the bulk density of the filler is 20kN / m 3 , internal friction angle Take 25°, cohesion c take 20kPa, foundation soil filler bulk density 19kN / m 3 , internal friction angle Take 35°, cohesion c take 10kPa, two-way geogrid 4 is set in 2 layers (ground layer width 23m, tensile strength 160kN / m, 3m layer in the middle of embankment, width 18m, tensile strength 120kN / m), force transmission The shear strength of the bar is 800kN at the ground and 400kN at the middle of the embankment, and the vertical spacing of reinforcement piles 1 is 6m.

[0074] A calculation method for an embankment pile-slab wall structure described in the present embodiment comprises the following steps,

[0075] ①Determine the surface friction coefficient f between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com