Flexible composite lining segment

A technology of composite lining and segment, applied in wellbore lining, tunnel lining, shaft equipment, etc., can solve problems such as load concentration, achieve the effect of good working environment, avoid damage, and enhance overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

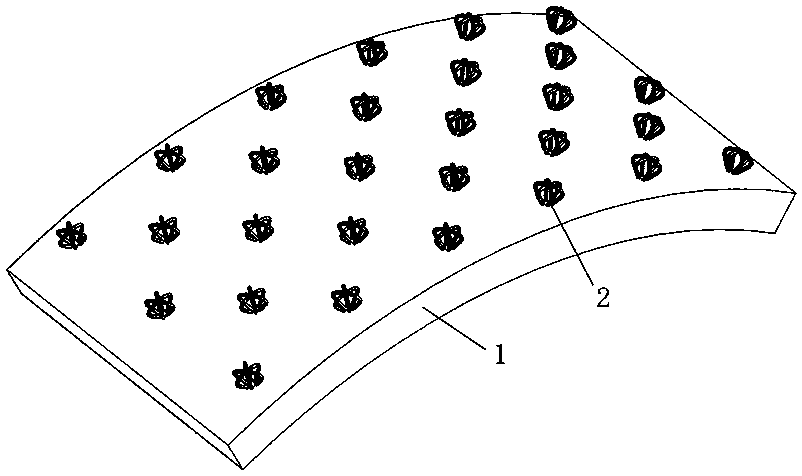

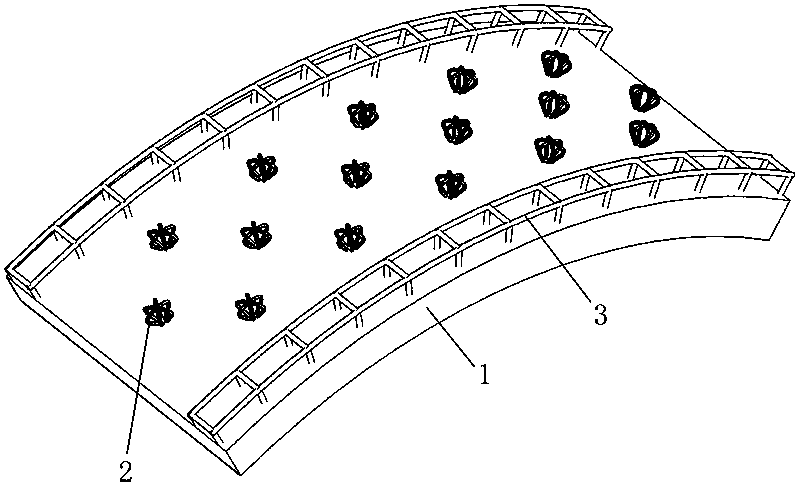

[0028] Such as figure 1 with 2 As shown, a flexible composite lining segment includes a lining body 1, a flexible body 2 and an arch 3. The flexible body 2 is located on the outside of the lining body 1 , and one end is implanted into the lining body 1 .

[0029] The inner surface of the lining body is flat or arc-shaped, and is arranged in blocks, and the block lining bodies are spliced into a ring in the circumferential direction, and spliced into a pipe in the axial direction. The connection between the link and the lining body between the pipes is no connection, tongue and groove connection, bolt connection, ball joint connection or socket connection. The lining body is a reinforced concrete segment, a prestressed concrete segment, a steel pipe segment or a composite segment.

[0030] The flexible body is bundle-shaped, and its section is circular, rectangular, elliptical or multi-circle twisted into a bundle, and its arrangement is quincunx, hexagonal or circular. ...

Embodiment 2

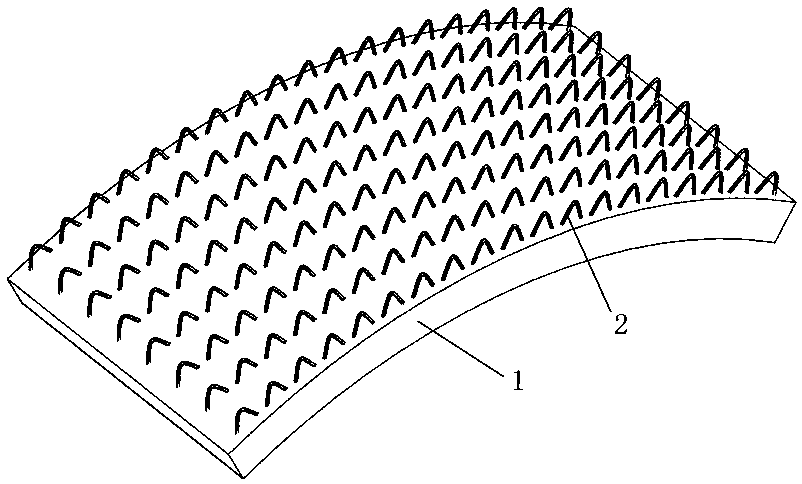

[0035] Such as image 3 with 4 As shown, a flexible composite lining segment includes a lining body 1, a flexible body 2 and an arch 3. The flexible body 2 is located on the outside of the lining body 1 , and one end is implanted into the lining body 1 .

[0036] The inner surface of the lining body is flat or arc-shaped, and is arranged in blocks, and the block lining bodies are spliced into a ring in the circumferential direction, and spliced into a pipe in the axial direction. The connection between the link and the lining body between the pipes is no connection, tongue and groove connection, bolt connection, ball joint connection or socket connection. The lining body is a reinforced concrete segment, a prestressed concrete segment, a steel pipe segment or a composite segment.

[0037] The flexible body is in the shape of a belt, and its section is round, rectangular, oval or multi-circle twisted into a bundle, and the arrangement is quincunx, hexagonal or round. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com