Method for measuring non-contact printing ink content in waster paper pulp and deinking effect evaluation method

A technology of printing ink and measurement method, which is applied in the field of secondary fiber recycling, can solve the problems of inaccurate representation of the actual ink content and large errors, and achieve the effects of intuitive detection results, strict detection process, and small detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The demarcation of iron content in the ink of embodiment 1

[0035] Place a group of A4 papers in a constant temperature and humidity room, weigh them after 24 hours, and take samples to measure the moisture content; then double-sided laser printing, the printed content on each page is fixed, and continue to be placed in the same temperature and humidity room time, weigh and measure moisture in the same way. Calculate the quality difference (dry weight) of the group of A4 papers before and after printing to obtain the amount of ink on the printing paper (dry weight). Comparing the amount of ink (absolute dry quantity) with the quality of the corresponding printing paper (absolute dry quantity), that is, the content of ink (absolute dry quantity) relative to printing paper (absolute dry quantity) in this printing mode, calculated Ink content T' in waste paper pulp p = 2.818%.

[0036] Take the above-mentioned double-sided laser printed A4 paper and 160g (dry weight) o...

Embodiment 2

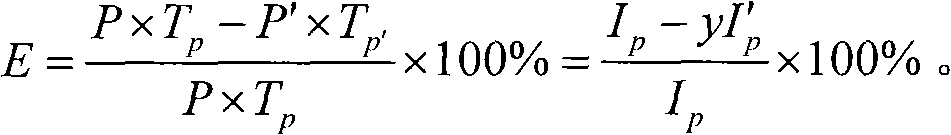

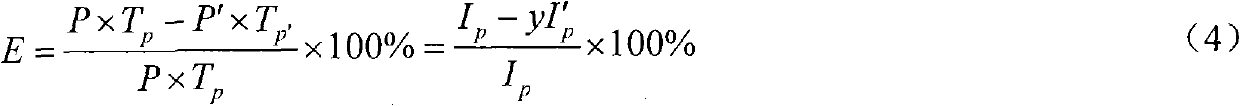

[0039] Take 160g (dry weight) double-sided printing laser printing paper, the specification is A4, print a fixed content on each page (to ensure stable ink volume), and place it in a plastic sealing bag for 24 hours to balance the moisture after printing. Then disintegrate into 6.3mm wide paper strips with a paper shredder, put into the Adirondack Formax pulper, add 0.0025% deinking agent BRD 2349 (mass percentage relative to the absolute dry pulp), at 15% thick, 65 Disintegrate for 25 minutes under the condition of ±2°C, then take 100g (absolutely dry weight) of the crushed pulp, dilute it to 1% pulp concentration, pour it into the Denver D 12 flotation cell, and float at 43±2°C for 5 minute. Take the pulp samples of crushed pulp and flotation good pulp respectively (at the same time, take another sample to measure the moisture content), dry and carbonize, then burn the ash in the muffle furnace, and calculate the ash content A in the pulp before and after flotation p and A'...

Embodiment 3

[0043] Take 160g (dry weight) double-sided printing laser printing paper, the specification is A4, print a fixed content on each page (to ensure stable ink volume), and place it in a plastic sealing bag for 24 hours to balance the moisture after printing. Then disintegrate into 6.3mm wide paper strips with a paper shredder, put into the Adirondack Formax pulper, add 0.005% deinking agent BRD 2349 (mass percentage relative to the absolute dry pulp), at 15% thick, 65 Disintegrate for 25 minutes under the condition of ±2°C, then take 100g (absolutely dry weight) of the crushed pulp, dilute to 1% pulp concentration, pour it into the Denver D 12 flotation cell, and float at 43±2°C for 5 minute. Take the pulp samples of crushed pulp and flotation good pulp respectively (at the same time, another sample is taken to measure the moisture content), after drying and carbonization, burn the ash in the muffle furnace, and calculate the ash content A in the pulp before and after flotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com