Optical fiber rapid cold connective device

A splicing device and fast technology, applied in the coupling of optical waveguide, etc., can solve the problems of inconvenient addition of matching liquid and stability, increase of production cost, complex packaging, etc., and achieve the requirements of simple structure, improved accuracy, and reduced processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

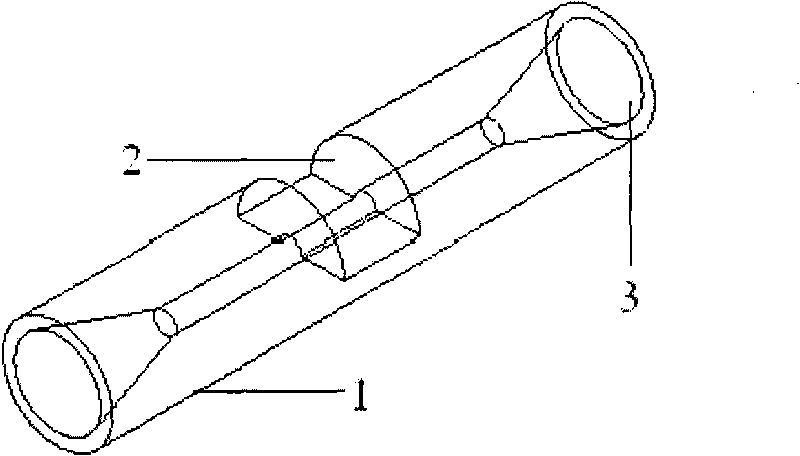

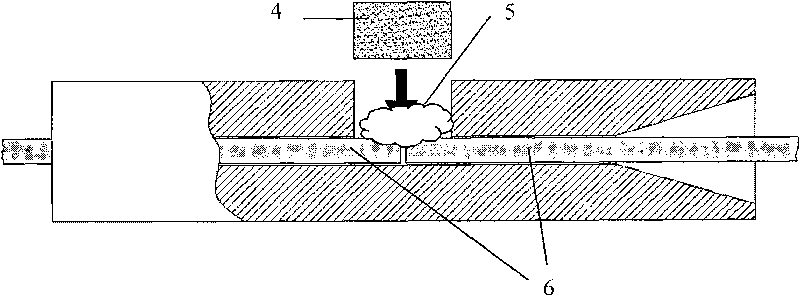

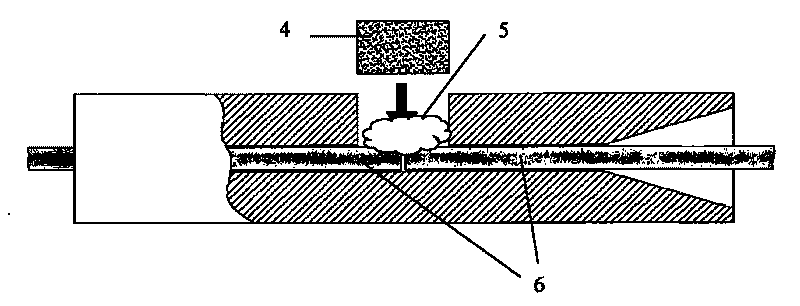

[0009] The device includes a hollow tube 1 and a briquetting block 4, the hollow tube 1 is a hollow core tube with a nominal aperture, the middle part of the hollow tube 1 has an opening to form a C-shaped groove 2, and the two ends of the hollow tube are A conical guide port 3 is provided, and the pressing block 4 is located in the C-shaped groove 2 when practical. The junction point of the optical fiber 6 to be connected is located in the middle of the C-shaped groove 2 of the hollow tube. The diameter of the hole in the hollow tube 1 is slightly larger than the outer diameter of the optical fiber 6 to be connected. In order to facilitate the insertion of the optical fiber, the inner diameter of the hollow tube is slightly larger than the outer diameter of the optical fiber to be connected, and there are guide ports with tapered structures at both ends. The end faces of the two optical fibers to be connected can easily reach the middle of the C-shaped groove 2 of the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com