High-voltage megawatt-grade high-power resistance

A high-power resistance, megawatt-level technology, applied in the direction of resistors, non-adjustable metal resistors, non-adjustable liquid resistors, etc., can solve the problems of high cost and large resistance volume of alloy materials, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

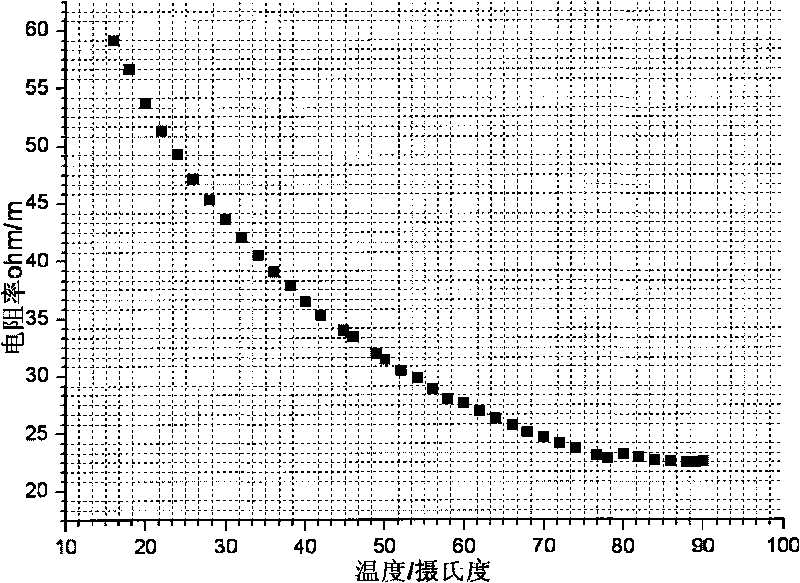

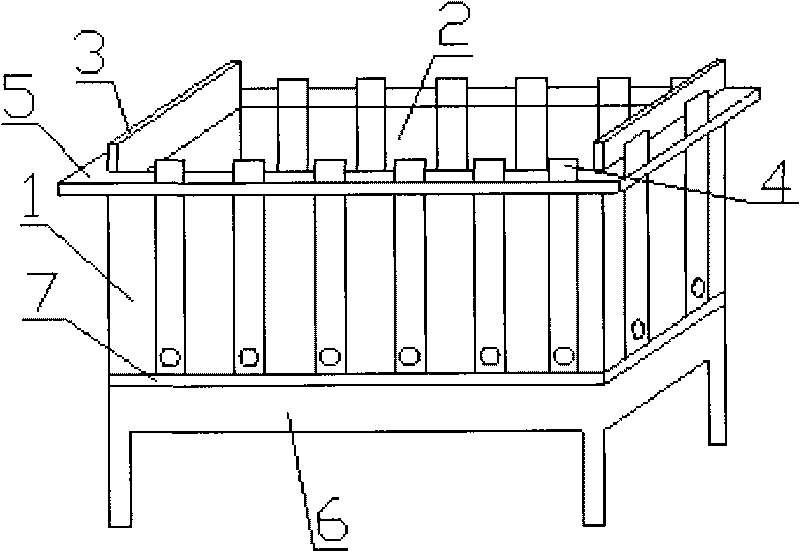

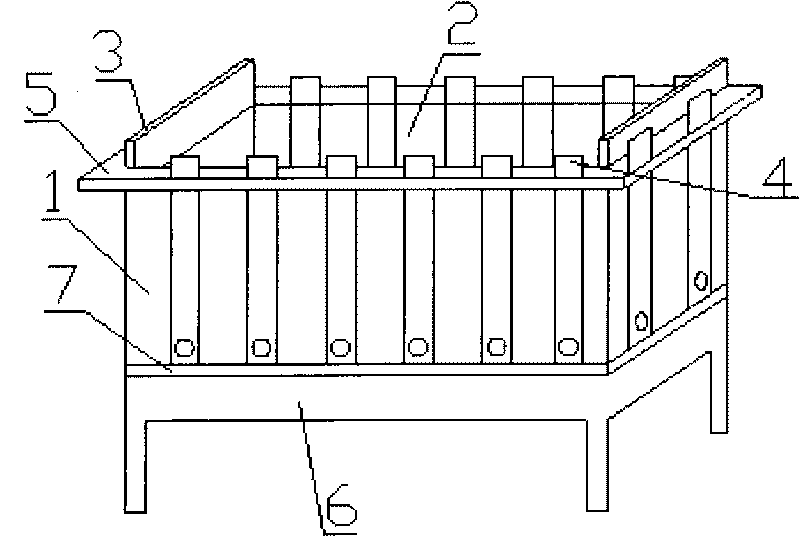

[0024] The high-voltage megawatt-level high-power resistor includes a container 1 made of insulating material, and water 2 is contained in the container 1 as a resistance medium. The height of the container 1 is higher than that of the water 2 in the container 1, and it also includes a metal electrode plate 3 , the metal electrode plates 3 are respectively inserted into the water 2 along the two side walls of the container 1, and cling to the two side walls of the container 1, as the terminals of the resistance. The water resistor is connected to the circuit through the metal electrode plate 3 for use. Heating makes the water in the container 1 boil, and obtains a water resistance with stable resistance. The shape of the container 1 is cylindrical, semi-cylindrical, cuboid, cone or sphere, and the cross-sectional area of the container 1 is rectangular; the container 1 is open or sealed; the external of the container 1 has reinforcing ribs 4 for fixing. When the container 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com