Thin temperature fuse with cushion layer structure and preparation method thereof

A technology of temperature fuse and layer structure, which is applied in the manufacture of fuses, electrical components, circuits, etc. It can solve the problems of potential danger in the underlying technology, unsafe mobile phone batteries, and imperfect manufacturing technology of lithium batteries, so as to save spot welding Auxiliary bending feet, firm welding, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

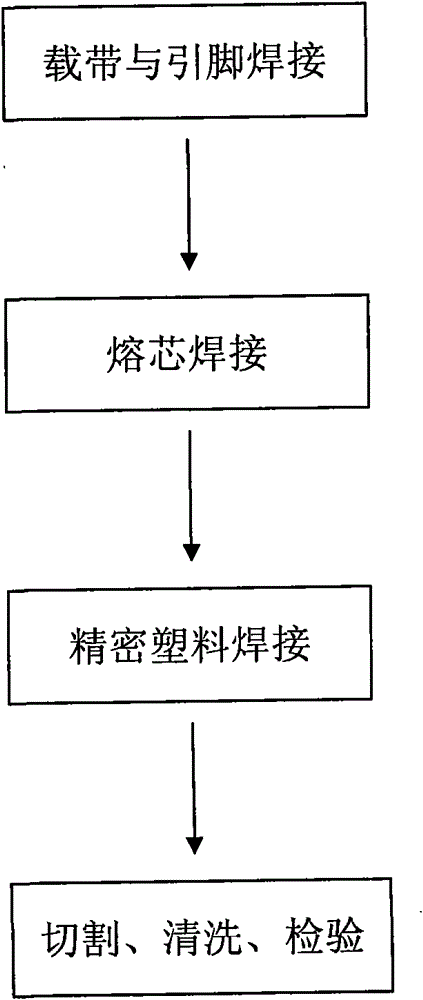

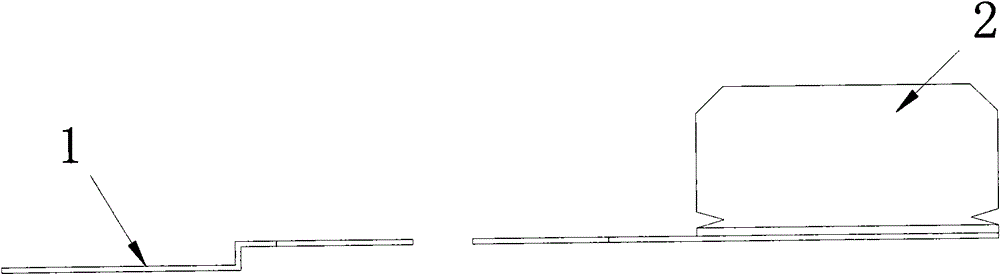

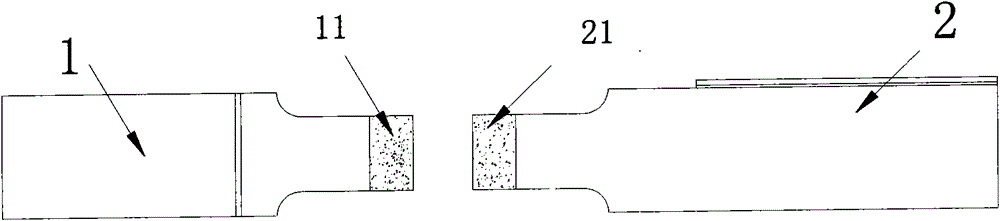

[0047] see figure 1 It is a process flow diagram of the present invention, figure 2 It is a schematic diagram of the front view structure of the metal pin of the present invention, image 3 It is a top view structure schematic diagram of the metal pin of the present invention, Figure 4 It is a top view structure schematic diagram of the download tape of the present invention, Figure 5 It is a schematic diagram of the top view structure of the welding of the metal pin and the download chip of the present invention, Figure 6 It is a schematic top view structure diagram of the carrier tape in the present invention, Figure 7 It is a top view structural schematic diagram of welding of the carrier tape and the metal pin in the present invention, Figure 8 It is a top view structural schematic diagram of welding of the fusible core and the ends of two metal pins of the present invention, Figure 9 It is the schematic diagram of the decomposition main section structure of e...

Embodiment 2

[0054] The preparation method, structure and size are the same as in Example 1, except that the width of the cushion layer of the intermediate carrier tape is different, and the width s is 0.5mm, and a thin thermal fuse (50pcs) is obtained.

Embodiment 3

[0056] The preparation method, structure and size are all the same as in Example 1, except that the width and thickness of the cushion layer of the intermediate carrier tape are different. The width s is 0.5mm and the thickness is 0.05mm, and a thin thermal fuse (50pcs) is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com