Nonmetallic vibration film multilayer piezoelectric speaker

A piezoelectric speaker, non-metallic technology, applied in the field of microphones, to achieve the effect of reducing total harmonic distortion, reducing distortion, and improving sound pressure output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

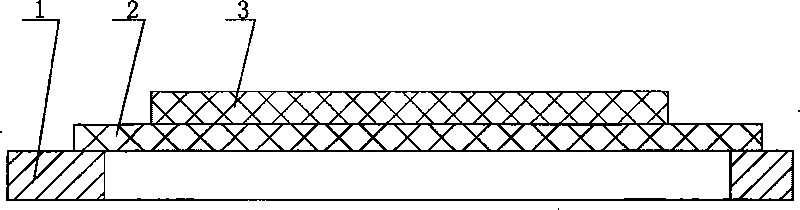

[0017] exist figure 1 , 2 Among them, the non-metallic diaphragm multilayer piezoelectric loudspeaker of this embodiment is composed of a frame 1 , a nonmetallic elastic diaphragm 2 , and a multilayer piezoelectric ceramic sheet 3 .

[0018] A non-metallic elastic vibrating film 2 is fixedly bonded to the frame 1 with glue, and a multilayer piezoelectric ceramic sheet 3 is bonded to the non-metallic elastic vibrating film 2 with glue.

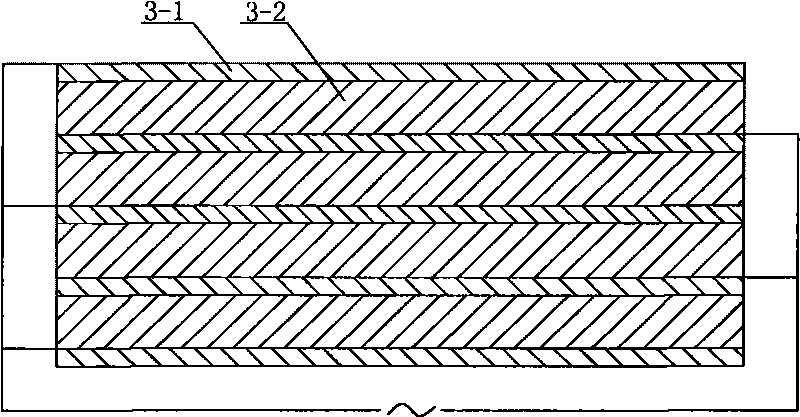

[0019] The multilayer piezoelectric ceramic sheet 3 of this embodiment is made by laminating and sintering 4 layers of piezoelectric ceramic layers 3-2 and 5 layers of electrode layers 3-1, and one layer of piezoelectric ceramic layer 3-2 is laminated with an adjacent layer An electrode layer 3-1 is arranged between the electric ceramic layers 3-2, and the electrode layer 3-1 is made of Ag / Pd electrode material, and an electrode layer 3 is arranged on the outer surfaces of the two outermost piezoelectric ceramic layers 3-2. -1, the electrode ...

Embodiment 2

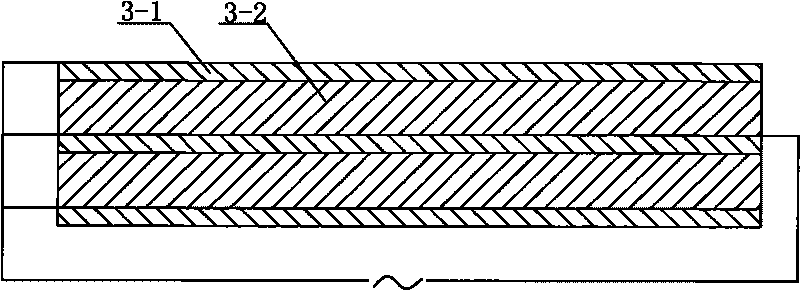

[0022] In this embodiment, the multilayer piezoelectric ceramic sheet 3 is made by laminating and sintering two piezoelectric ceramic layers 3-2 and three electrode layers 3-1, and a An electrode layer 3-1 is provided on the outer surfaces of the two piezoelectric ceramic layers 3-2, and an electrode layer 3-1 is provided on the outer surfaces of the two piezoelectric ceramic layers 3-2, and the electrode layers 3-1 on the outer surfaces of the two piezoelectric ceramic layers 3-2 are respectively connected to AC power The electrode layer 3-1 between the two piezoelectric ceramic layers 3-2 is connected to the other end of the AC power supply. The non-metallic elastic diaphragm 2 is the same as that in Embodiment 1. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0024] In this embodiment, the multilayer piezoelectric ceramic sheet 3 is made by stacking and sintering 9 piezoelectric ceramic layers 3-2 and 10 electrode layers 3-1, and one piezoelectric ceramic layer 3-2 is adjacent to one An electrode layer 3-1 is provided between the piezoelectric ceramic layers 3-2, and an electrode layer 3-1 is provided on the outer surfaces of the two outermost piezoelectric ceramic layers 3-2, and each piezoelectric ceramic layer 3-2 The electrode layer 3-1 on one side is connected to one end of the AC power supply, and the electrode layer 3-1 on the other side is connected to the other end of the AC power supply. The non-metallic elastic diaphragm 2 is the same as that in Embodiment 1. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0025] In order to verify the beneficial effects of the present invention, the inventors used the non-metallic diaphragm multilayer piezoelectric speaker prepared in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com