Physical amount change history recording method, its program, flow rate measuring device, and fluid supply system

A flow measurement device and physical quantity technology, applied in the direction of measuring flow/mass flow, measuring device, liquid/fluid solid measurement, etc., to achieve the effects of reducing storage capacity, improving calculation speed and recognition accuracy, and simplifying calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described with reference to the drawings.

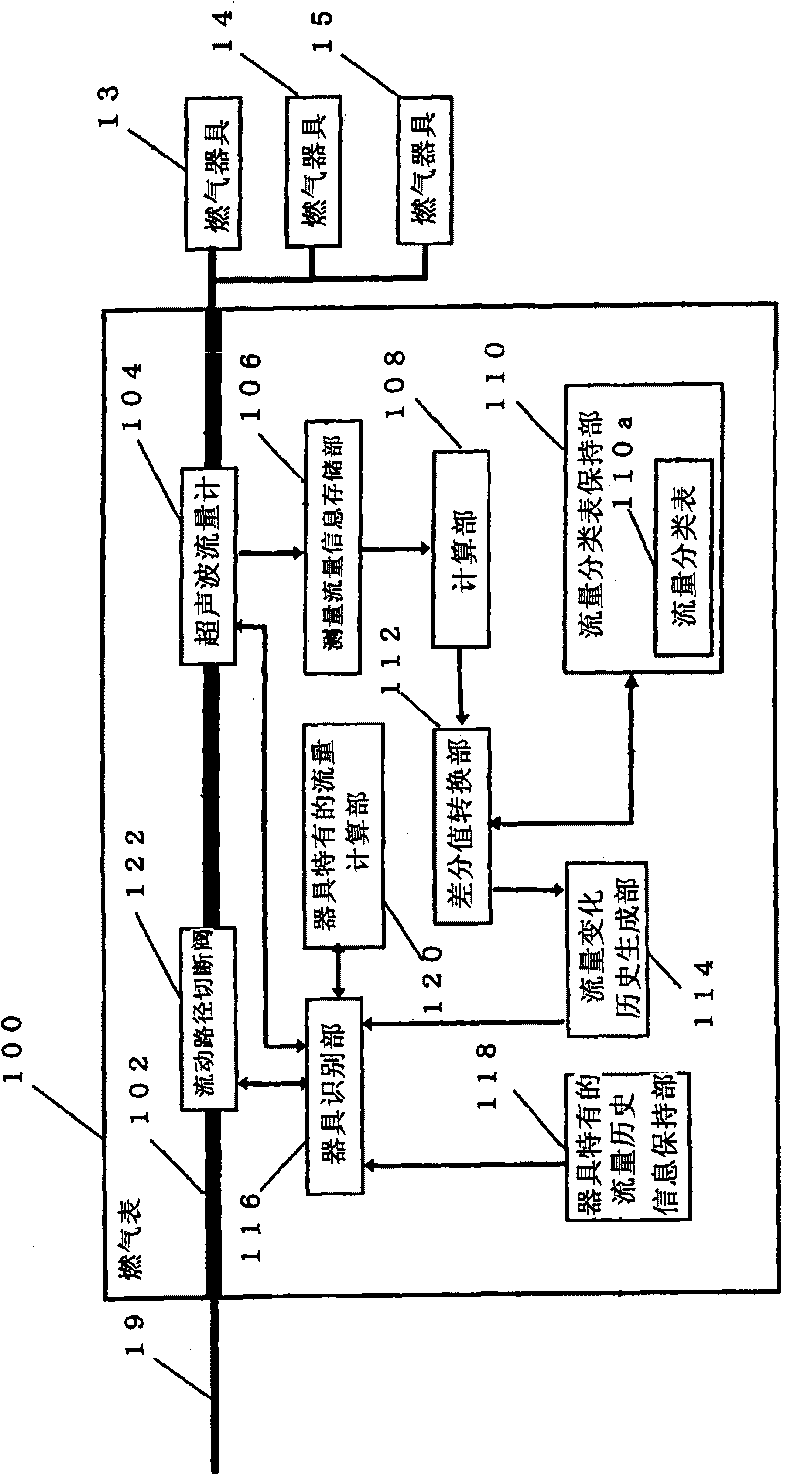

[0041] figure 1 It is a block diagram of a gas meter as a flow measuring device (physical quantity measuring device) in an embodiment of the present invention.

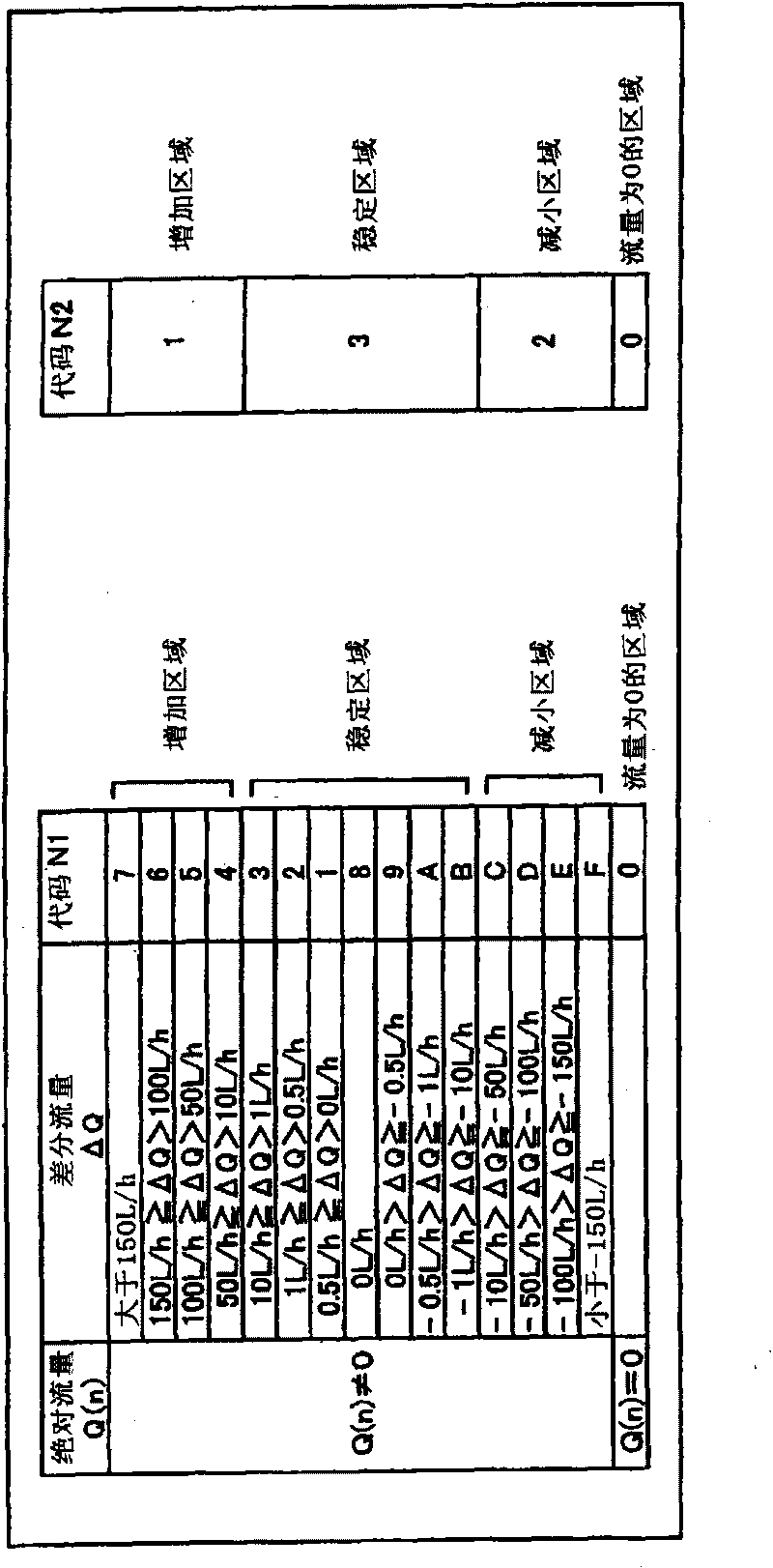

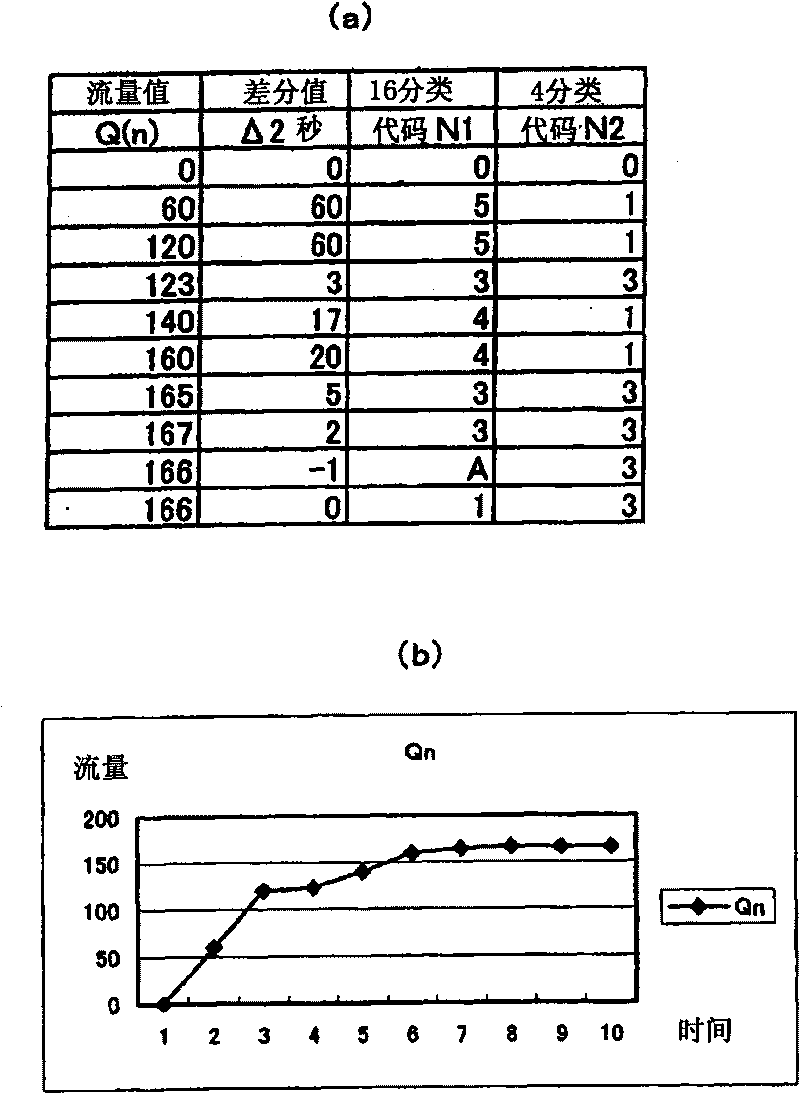

[0042] figure 1 Among them, the gas meter 100 includes: a flow path 102, an ultrasonic flowmeter 104 as a flow measurement unit, a measured flow information storage unit 106, a calculation unit 108, a flow classification table storage unit 110, a differential value conversion unit 112, and a flow change history generation unit. 114 , an appliance identification unit 116 , and an appliance-specific flow history information storage unit 118 . The gas meter 110 further includes a flow path shutoff valve 122 on the flow path 102 for shutting off gas in an emergency or the like.

[0043] The ultrasonic flowmeter 104 emits ultrasonic waves at given time intervals (for example, two seconds, etc.) to gas as a fluid flowing in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com