Repairing and polishing device for redundant brazing filler metal of precision components

A kind of precision parts and redundant technology, applied in the field of welding auxiliary equipment, can solve the problems of difficult to guarantee the design requirements and low efficiency, and achieve the effect of ensuring the quality of repair and polishing, reducing vibration and overcoming difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is a repairing and polishing device for redundant solder of precision parts, and is used for processing engine guide vanes.

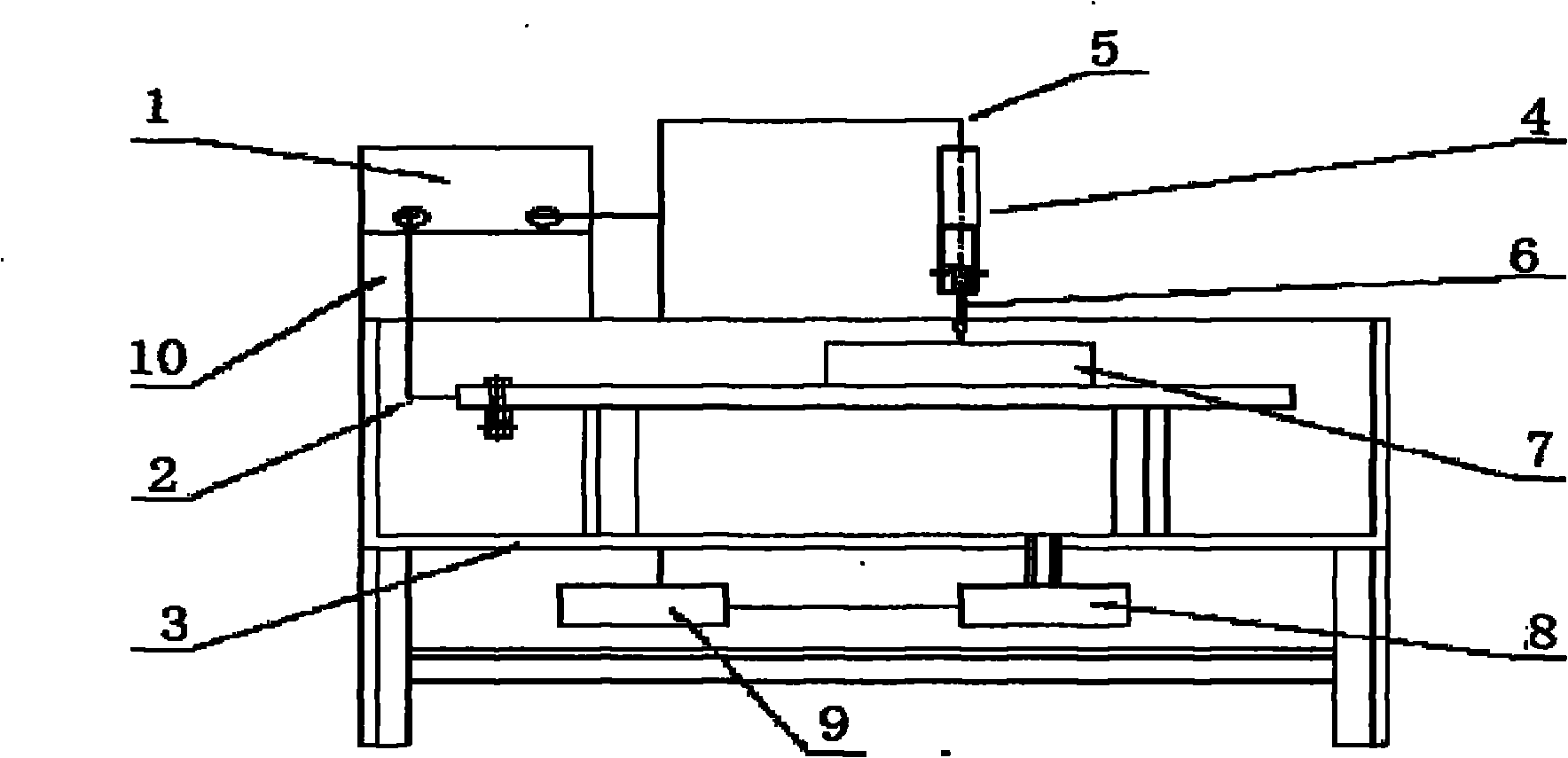

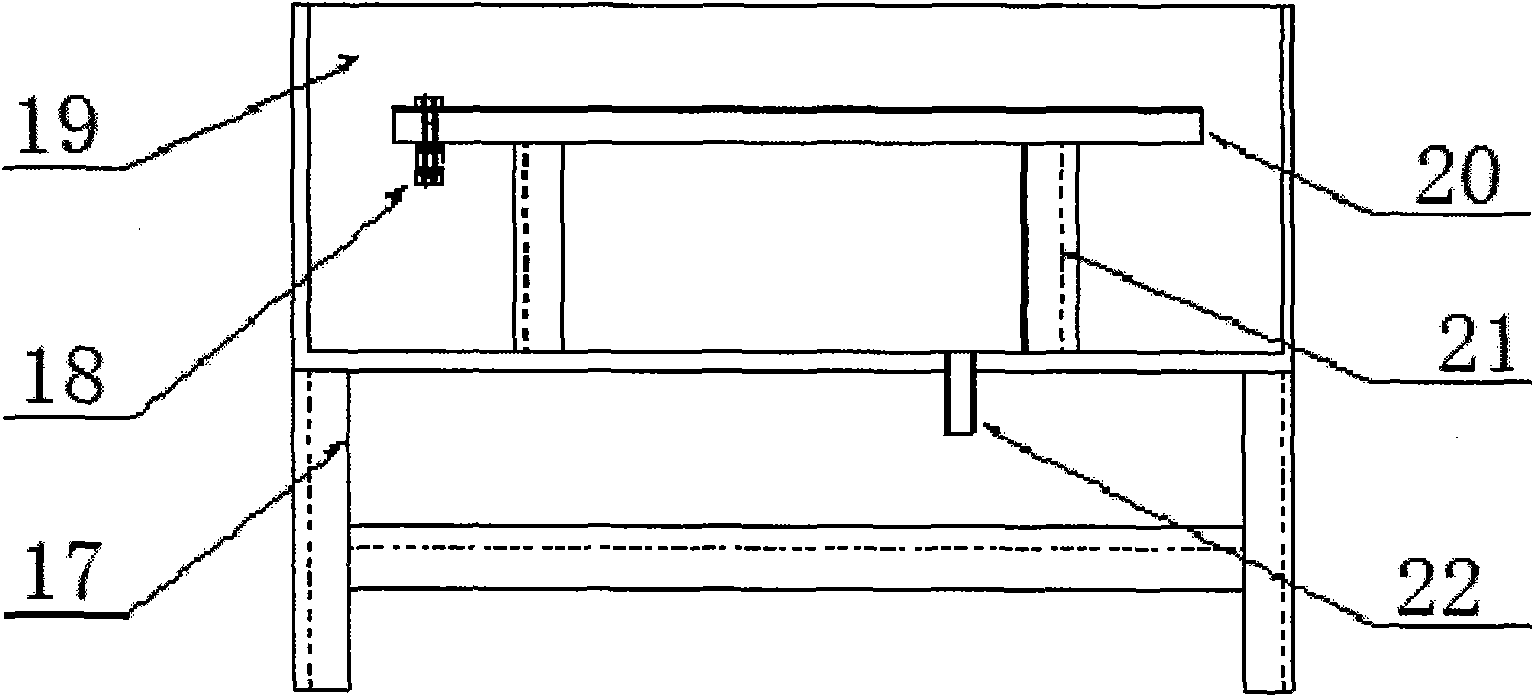

[0024] This embodiment includes a power supply 1 , a workbench 3 , a miniature polishing gun 4 , a sandwich hollow pipeline 5 , an electromechanical composite processing head 6 , an electrical connector 7 and a controller 10 . in,

[0025] The power supply 1 adopts a high-frequency pulse precision power supply.

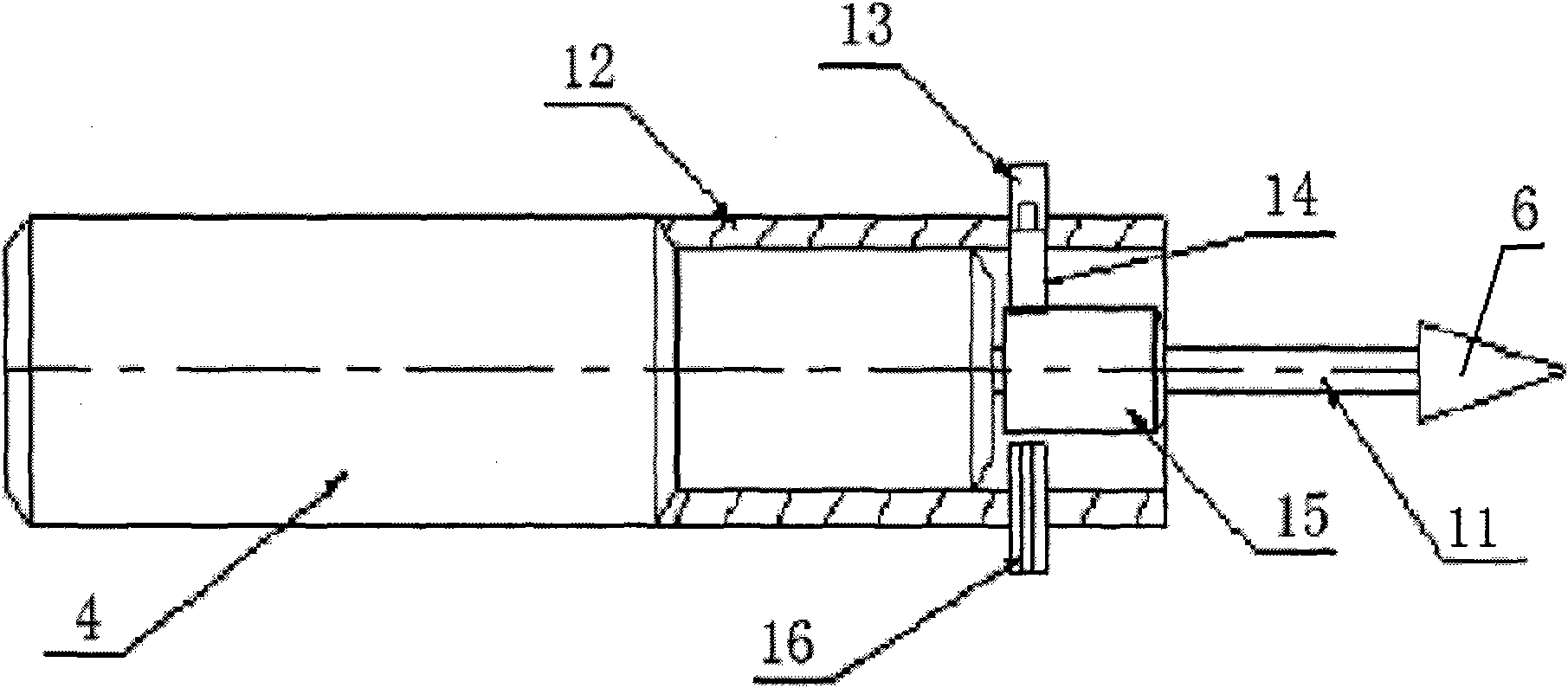

[0026] The electromechanical composite processing head 6 includes an electromechanical composite polishing head and an electromechanical composite polishing head, which are selected and used according to the spread of the workpiece 7 solder. The electromechanical composite polishing head and the electromechanical composite polishing head all have the conical working head of polishing or polishing at one end of the clamping rod 11;

[0027] The interlayer hollow pipeline 5 is to install an inner insulating tube 25 on the...

Embodiment 2

[0034] This embodiment is a repairing and polishing device for redundant solder of precision parts, and is used for processing engine guide vanes.

[0035] This embodiment includes a power supply 1 , a workbench 3 , a miniature polishing gun 4 , a sandwich hollow pipeline 5 , an electromechanical composite processing head 6 , an electrical connector 7 and a controller 10 . in,

[0036] Power supply 1 adopts high-frequency pulse precision power supply.

[0037] The electromechanical composite processing head 6 includes an electromechanical composite polishing head and an electromechanical composite polishing head, which are selected and used according to the spread of the workpiece 7 solder. The electromechanical composite polishing head and the electromechanical composite polishing head all have the conical working head of polishing or polishing usefulness at one end of the clamping rod 11;

[0038] The interlayer hollow pipeline 5 is an additional layer of inner insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com