Low-acid and efficient diesel antiwear additive and preparation method thereof

An anti-wear agent, low-sulfur diesel technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of small source of raw materials, high cost, complex production process, etc., and achieve the effect of significant anti-wear effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] One technical feature of the invention is that the raw materials are readily available and can be directly purchased from existing products in the market; another technical feature is that the production process is simple, and the production conditions are mild and easy to implement.

[0036] Therefore, after obtaining the specific raw material composition and mass ratio, industrialized production can be quickly realized in accordance with specific production procedures.

[0037] The following examples will further illustrate the invention, but do not limit the invention in any way.

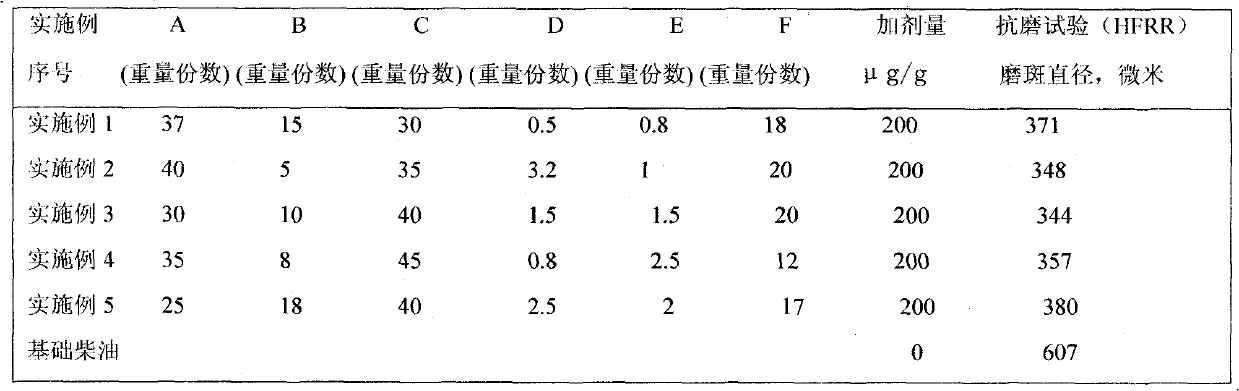

[0038] Table 1

[0039]

[0040] Note: Anti-wear test (HFRR) is a high-frequency reciprocating anti-wear test method, SH / T0765-2005

[0041] It can be seen from Table 1 that within the dosage range of each component given in the present invention, better anti-wear effects can be obtained.

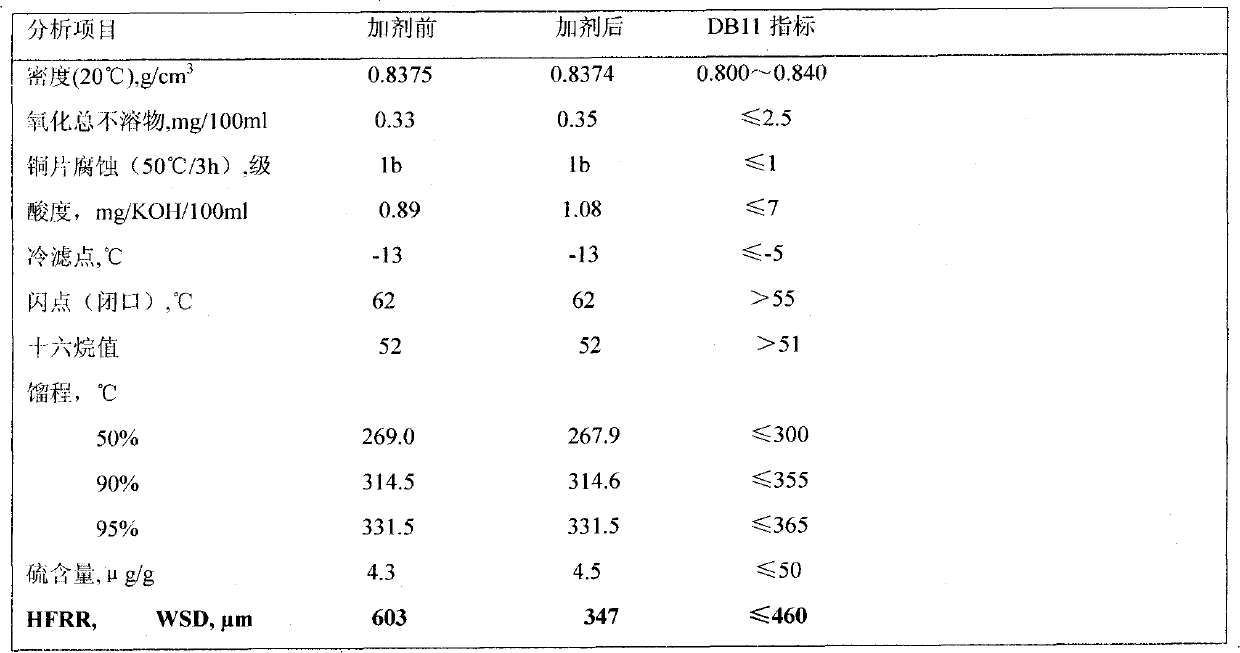

[0042] The anti-wear agent of the present invention has no adverse effect on the index of diese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com