Blocking ball device for horizontal well core drill

A technology of coring drilling tools and plugging balls is applied in the direction of extraction of undisturbed cores, earthwork drilling, etc., which can solve the problems of easily entering the jetting and reverse drilling tools by mistake, affecting the single-pass recovery rate of cores, etc., and achieves the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

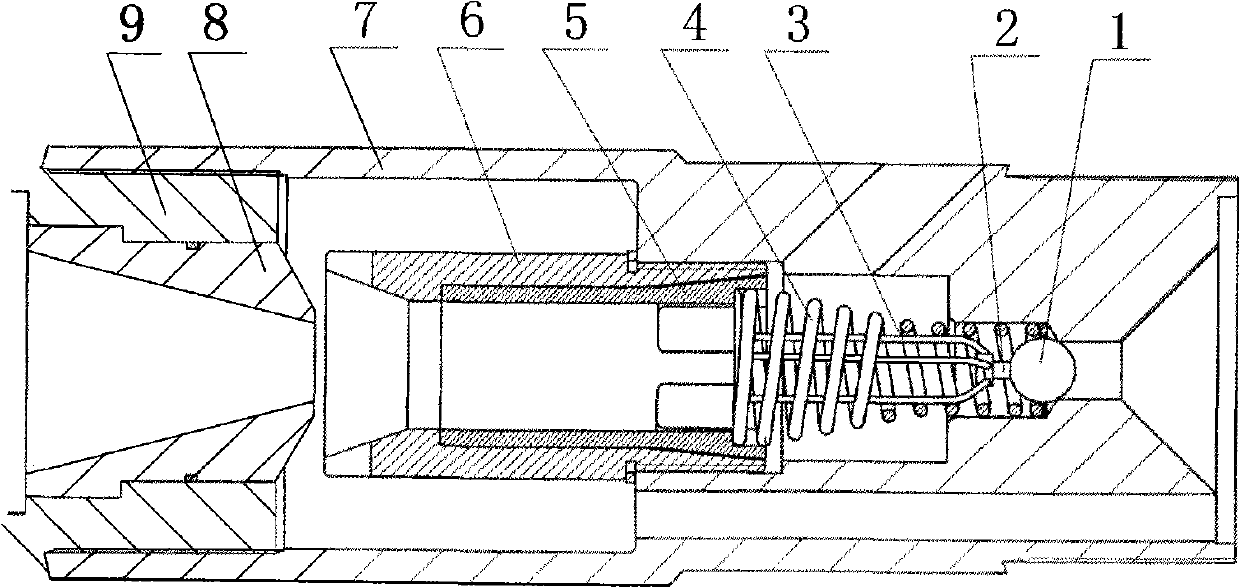

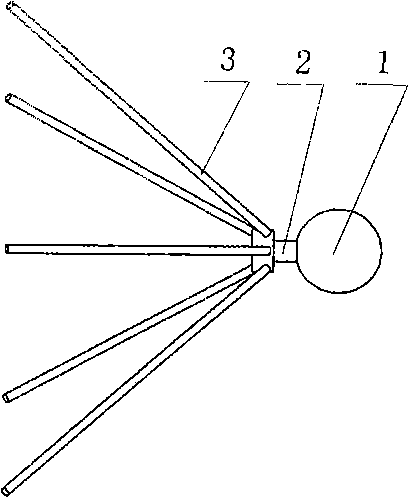

[0021] Embodiment 1: make horizontal well coring tool plugging ball device of the present invention, its structure is as follows figure 1 As shown, it includes a plugging ball, a conical spring and an anti-spray mechanism; wherein, the spray cavity of the anti-spray mechanism adopts a double-layer structure combining inner and outer shells, and a through hole is drilled in the middle of the base of the spray cavity of the anti-spray mechanism to form the center of the drill tool. Flow channel, the diameter of the drilled through hole is smaller than the diameter of the sphere 1 that blocks the ball. The conical spring is installed between the spray cavity inner sleeve 5 and the spray cavity base 7 of the spray reverse mechanism, and passes through the spray cavity outer cover 6 and the spray cavity base. The connecting threads between 7 are fixed, and the inner diameter of the conical spring cone top is slightly larger than the outer diameter of the plugging ball spheroid.

[...

Embodiment 2

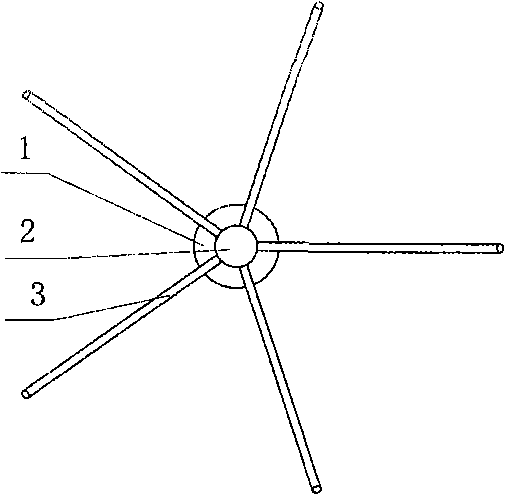

[0023] Embodiment 2: the plugging ball device of the horizontal well coring tool of the present invention made in embodiment 1 is installed in the coring tool, and the installed position is as follows Figure 4 As shown, the drilling tool is lowered into the bottom of the horizontal well, that is, after the drilling tool reaches the working position, the drilling fluid can be used to directly flush the bottom of the horizontal well through the center hole of the drilling tool, and the cuttings accumulated in the well can be carried back up. After the bottom of the well is cleaned, Put in the plugging ball, carried by the drilling fluid, the plugging ball reaches the anti-spray mechanism, falls into the conical spring under the guidance of the conical spring, the guide spring is automatically retracted, the steel ball accurately blocks the center hole, and the anti-spray mechanism resumes spraying. Anti-function and immediate suction effect. Using the device of the invention ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com